Explore the role of ESD grounding cords in preventing electrostatic discharge, their types, best usage practices, and importance in workplace safety.

Understanding ESD Grounding Cords

Electrostatic Discharge (ESD) grounding cords are critical components in many workplaces and environments where the build-up and sudden discharge of static electricity can have detrimental effects. These devices work to eliminate this risk, offering a safer and more reliable working environment.

The Significance of ESD Grounding Cords

ESD events can occur when differently charged objects come into contact or close proximity, leading to a sudden flow of electricity from one to the other. This can pose risks to both equipment and individuals, especially in industries like electronics manufacturing, where components are highly sensitive to electrical discharge. Here is where ESD grounding cords come into play.

- Protection of Equipment: ESD can cause severe damage to electronic components, sometimes causing complete failure. ESD grounding cords are designed to prevent such events, channeling static electricity safely to the ground.

- Preventing Accidents: A sudden ESD can lead to accidents, potentially causing harm to personnel in the vicinity. ESD grounding cords help to mitigate such risks.

- Maintenance of Data Integrity: In computing environments, an ESD event can corrupt data or cause systems to malfunction. Grounding cords are crucial for maintaining data integrity.

Components and Functionality

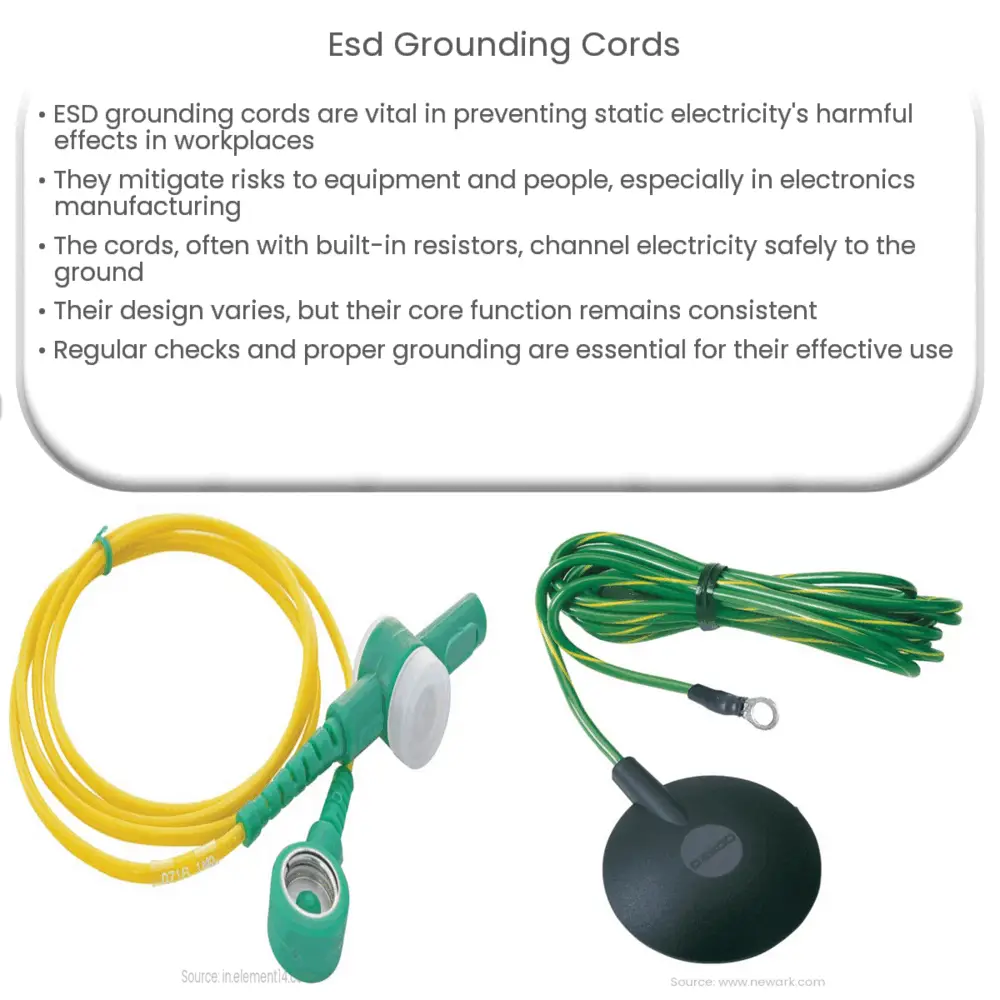

ESD grounding cords typically consist of a wire coated in insulating material, often incorporating a built-in resistor. This design enables them to effectively direct electrical charges to a grounded surface, limiting potential ESD events.

Grounding cords are usually connected to an ESD mat or similar surface, and the other end is attached to a ground point, such as a grounded metal structure or an electrical ground. This setup allows any built-up static charge to be safely and effectively discharged to the ground, preventing potential ESD events from occurring.

While the basic principle of operation remains constant, ESD grounding cords can differ based on their specific design, features, and standards they adhere to. This is especially important in different industry contexts, where varying levels of ESD protection may be required.

Different Types of ESD Grounding Cords

ESD grounding cords are available in various types and configurations, designed to cater to diverse requirements. Some of the common types include:

- Single-Wire Cords: These are the most common type of ESD grounding cords. They typically include one conductor and are used for standard ESD control applications.

- Dual-Wire Cords: These cords feature two conductors and offer continuous monitoring capabilities. They are commonly used in environments requiring more robust ESD protection.

- Coil Cords: These are grounding cords designed with a coiled wire, offering greater mobility and flexibility. They are typically used with ESD wrist straps.

Best Practices for Using ESD Grounding Cords

While using ESD grounding cords, certain best practices should be followed:

- Regularly check the cords for any damage or wear. This ensures they are in good working condition and providing adequate protection.

- Ensure the cords are properly grounded. A poorly grounded cord can lead to inadequate ESD protection.

- Replace faulty cords immediately. A faulty grounding cord can lead to severe consequences, including equipment damage and personal injury.

Conclusion

In conclusion, ESD grounding cords are a key element in managing and preventing Electrostatic Discharge (ESD) events in a wide range of industries, particularly in electronics manufacturing. They serve as a line of defense against potential damage to electronic components and people from static electricity. Understanding their functionality and the best practices for their use is crucial for anyone involved in an environment where ESD events could pose a threat. As such, investing in quality ESD grounding cords and following the recommended usage guidelines is an important step towards creating a safer and more reliable workspace.