Explore the importance of ESD Earth Bonding Points in managing electrostatic discharge, their installation, maintenance, and impact on workplace safety.

Understanding ESD Earth Bonding Points

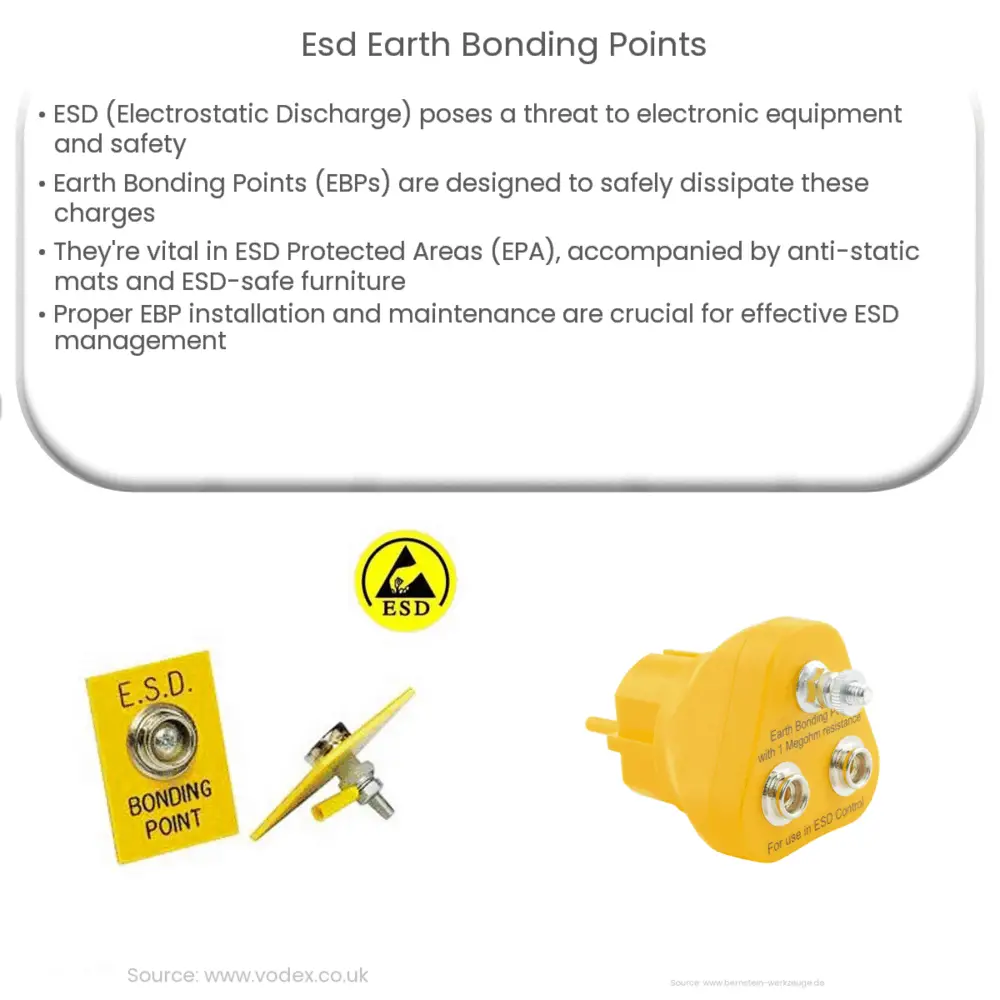

ESD (Electrostatic Discharge) is a serious concern in many industries. This invisible threat can damage electronic equipment, compromise safety, and even ignite flammable substances. Hence, managing ESD is paramount to ensuring both operational efficiency and workplace safety. An essential part of ESD management involves the use of earth bonding points. In this first part of our discussion, we will take a deep dive into understanding what these points are and why they are so important.

Defining ESD Earth Bonding Points

An Earth Bonding Point (EBP) is essentially a physical location designed to be electrically conductive. It is typically connected to the building’s grounding or earthing system. In the context of ESD, it provides a path for electrostatic charges to safely dissipate into the earth.

EBPs are not standalone items. They are part of an ESD Protected Area (EPA), which is a defined workspace where electronic components and assemblies susceptible to ESD damage can be handled safely. Other key elements of an EPA include anti-static mats, ESD-safe furniture, and personal grounding equipment such as ESD wrist straps and footwear.

The Importance of ESD Earth Bonding Points

The role of earth bonding points in managing ESD cannot be overstated. They help to:

- Prevent the buildup of electrostatic charges. By providing a pathway for these charges to the earth, EBPs help to keep all items and personnel within an EPA at the same electrical potential.

- Protect sensitive electronic components. Excessive electrostatic charges can cause catastrophic or latent damage to these components. By effectively controlling ESD, EBPs help to maintain the integrity of electronic products, thus preventing costly failures and rework.

The Installation of ESD Earth Bonding Points

Installing EBPs is a critical step in setting up an effective EPA. It requires careful planning and adherence to specific standards, such as ANSI/ESD S6.1, which provides guidelines for grounding in an ESD control program. In the next part of this article, we’ll delve deeper into the steps and considerations for installing and testing ESD earth bonding points, and the crucial role they play in creating a safe and productive work environment.

Key Steps for Installing ESD Earth Bonding Points

Correct installation of ESD earth bonding points is crucial to their effectiveness. Here are the key steps to keep in mind:

- Choose the right location: EBPs should be installed at strategic locations within the EPA, such as workstations and storage areas, to maximize their reach.

- Use appropriate hardware: Install the EBPs using conductive materials that ensure a reliable connection to the ground.

- Connect to the ground: The EBP must be connected to the building’s grounding system using an earth bonding plug or a ground lead.

- Test for effectiveness: Once installed, the effectiveness of the EBP should be verified using an ohmmeter or an ESD surface resistance meter.

Maintaining ESD Earth Bonding Points

EBPs require regular maintenance and testing to ensure they continue to perform their function effectively. An ESD control program should include routine checks for the integrity of the ground connection and the surface resistance of the EBP. Any deviation from the standard requirements indicates a problem that needs immediate attention.

Creating a Safe and Productive Environment

ESD Earth Bonding Points are an integral part of an ESD Protected Area (EPA), contributing significantly to a safe and productive work environment. By effectively managing ESD, they help to reduce equipment failures and improve the reliability of electronic products. It’s a win-win situation: enhancing operational efficiency and ensuring the safety of personnel and equipment.

Conclusion

In conclusion, ESD Earth Bonding Points are a key tool in managing the risks associated with Electrostatic Discharge. Their strategic placement, proper installation, and regular maintenance form an essential part of any ESD control program. By providing a pathway for electrostatic charges to safely dissipate, they help to protect sensitive electronic components and ensure the safety and productivity of the workplace. Thus, understanding and implementing ESD Earth Bonding Points is a must for anyone working in an environment dealing with electronic components.