Explore the working, benefits, and limitations of electrostatic precipitators, and discover future prospects in air pollution control.

Understanding Electrostatic Precipitators

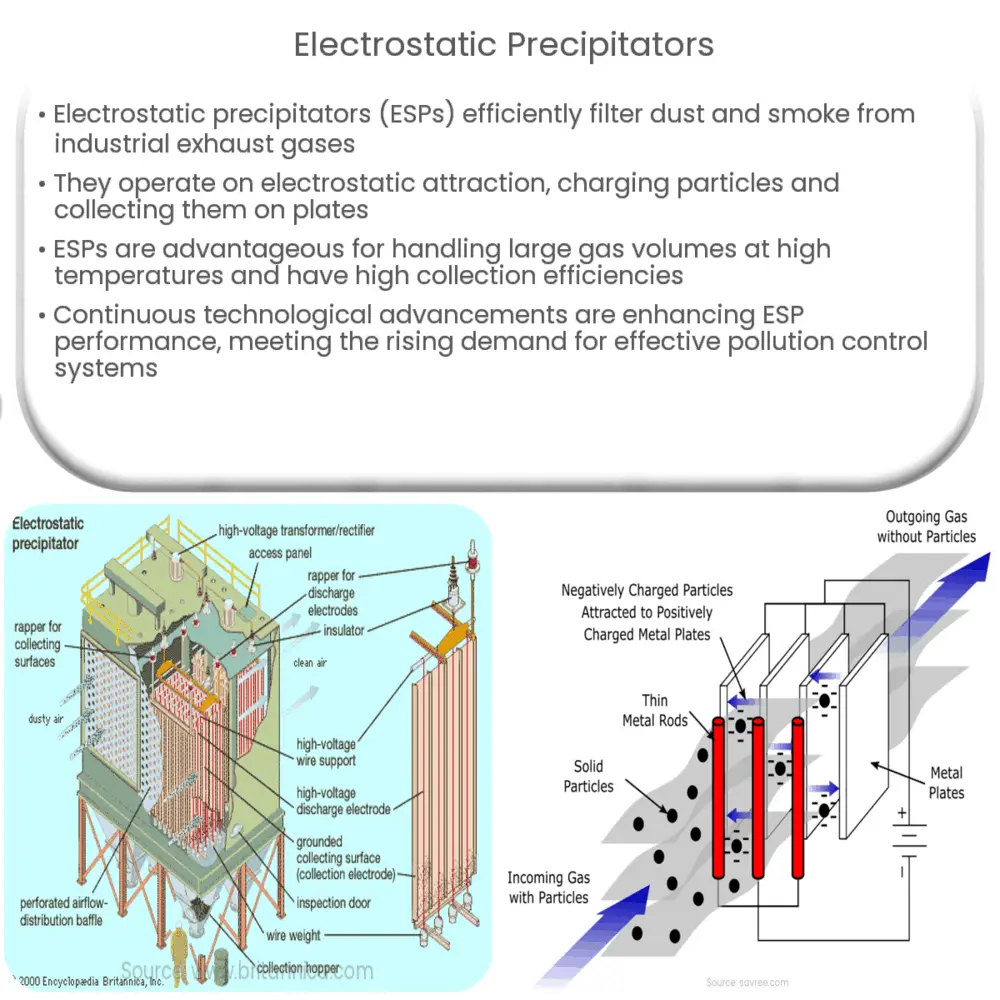

Electrostatic precipitators (ESPs) are one of the most effective and widely utilized devices designed to filter and eliminate fine particles like dust and smoke from industrial exhaust gases. The effectiveness of ESPs has made them a critical component in an array of applications, such as power plants, cement factories, steelworks, and various other industrial processes.

The Fundamental Principle

The concept of an electrostatic precipitator operates based on the principle of electrostatic attraction. Essentially, it involves imparting an electrical charge to particles, thereby making them adhere to a charged surface. Once these particles have been collected, they are then periodically removed, leaving the exhaust gases significantly cleaner.

Components and Operation

The main components of an electrostatic precipitator include the power supply, ionizing section, collection section, and the hopper. The operation of an ESP can be simplified into three steps.

- Ionization: In this phase, particles in the gas stream are ionized (given an electrical charge) in the ionizing section. This is achieved by generating a corona discharge using high-voltage electrodes.

- Collection: Once the particles are ionized, they are driven to a collecting electrode due to the electrostatic attraction. These electrodes are grounded, meaning they have a neutral charge, hence they attract the charged particles.

- Disposal: The collected particles form a layer on the collection plates. Over time, these plates are mechanically rapped, dislodging the particle layer which falls into a hopper for disposal.

The Benefits of Electrostatic Precipitators

ESPs offer a variety of advantages over other air pollution control equipment. They are capable of handling large volumes of gas at high temperatures, making them ideal for use in industrial settings. Additionally, their operating costs are relatively low as they use electrical energy instead of mechanical energy. Furthermore, they have high collection efficiencies, capable of removing more than 99% of particulate matter, depending on the specific application and design.

Challenges and Limitations

Despite their advantages, electrostatic precipitators do have certain limitations. They are less effective in removing very small particles and gaseous pollutants. Moreover, they can be sensitive to changes in operating conditions, such as the velocity and temperature of the gas stream, and the electrical properties of the particles. Additionally, the initial capital costs of these systems can be high.

Modern Developments and Improvements

Recent years have seen significant technological advancements in the field of electrostatic precipitators. Efforts have been concentrated on improving their performance, especially in the challenging conditions found in specific industries. For instance, innovations have been made to enhance their efficiency in removing fine particles and gaseous pollutants.

Some notable developments include the introduction of advanced electrode designs, the use of alternative materials for construction, and the integration of advanced control systems. These advancements not only increase the efficiency of ESPs but also extend their lifespan, thereby reducing long-term operating costs.

The Future of Electrostatic Precipitators

As we move forward, the demand for highly efficient and reliable air pollution control systems like electrostatic precipitators is set to increase. With the ongoing trend of stricter environmental regulations worldwide, the role of ESPs in mitigating industrial pollution becomes even more crucial.

In the future, we can expect further advancements in ESP technology, including improved designs and the use of smart technologies for real-time monitoring and control. The integration of ESPs with other emission control systems could also become a common practice to address a wider range of pollutants.

Conclusion

In conclusion, electrostatic precipitators are a vital tool in our battle against air pollution, especially in industrial settings. They operate on a simple principle, yet their impact on improving air quality is profound. While they do have certain limitations, continuous improvements and technological advancements are constantly enhancing their performance and efficiency. As we strive for a cleaner environment, the importance of electrostatic precipitators in achieving this goal cannot be understated.