Explore the workings of electrostatic motors, their design, applications, advantages, and future prospects in this comprehensive guide.

Introduction to Electrostatic Motors

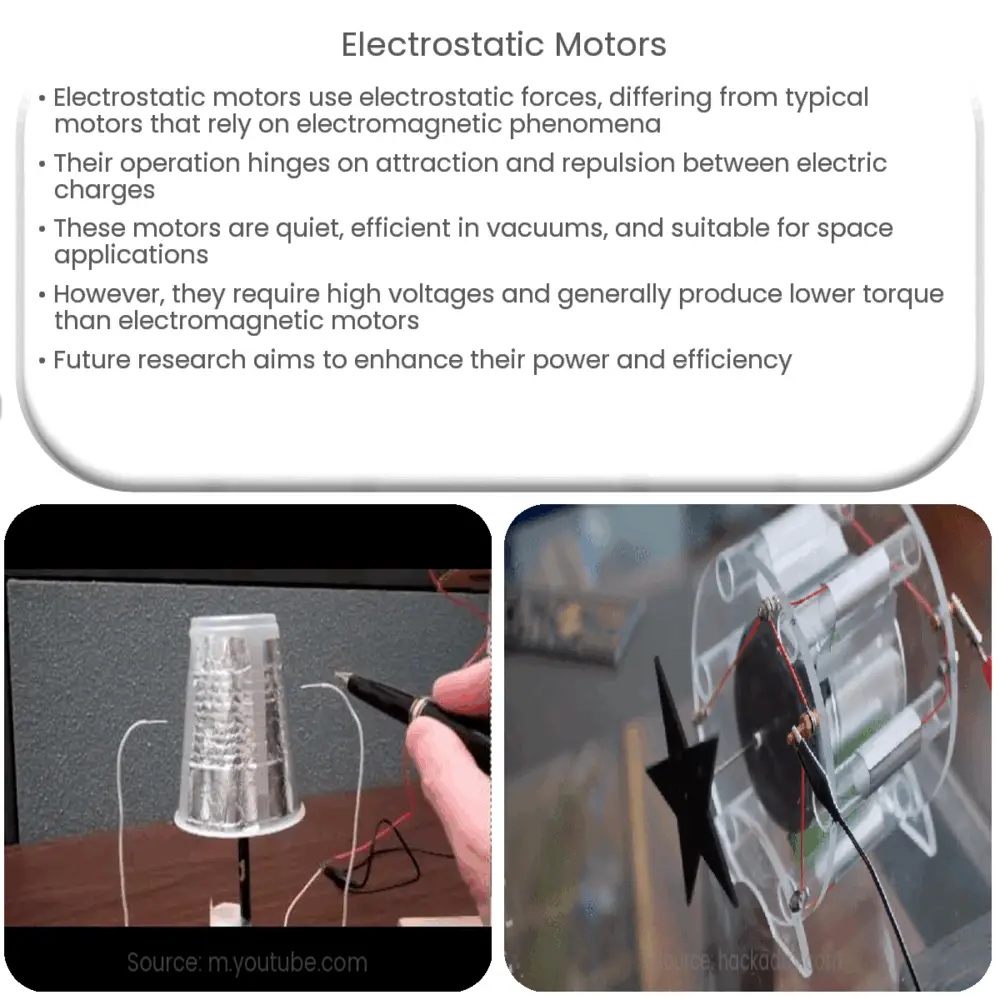

Electrostatic motors, often referred to as capacitor motors, represent a distinct category of electric motors which utilize electrostatic forces to generate mechanical motion. Unlike typical motors that rely on electromagnetic phenomena, these machines employ high voltage electrostatic fields to facilitate their operation.

Principles of Operation

The operation of an electrostatic motor primarily depends on the basic principles of electrostatics. The engine works on the concept of attraction and repulsion between electric charges. When voltage is applied, the charges on the stator (the stationary part of the motor) interact with the charges on the rotor (the rotating part), causing the rotor to move.

- Attraction Motor: In the simplest form of an electrostatic motor, a charged rotor is attracted towards a neutral or oppositely charged stator, causing it to rotate.

- Repulsion Motor: Alternatively, the rotor and stator can both be charged with like charges, so they repel each other, driving the rotor into motion.

These two types of action are often combined in practical motors, utilizing complex configurations of multiple rotors and stators. However, the fundamental principles of attraction and repulsion remain consistent throughout.

Design and Construction

Designing an electrostatic motor can be quite complex due to the need for high voltage and insulation. The design incorporates a rotor and a stator, much like a conventional electric motor. The rotor is made of conductive materials such as metal, while the stator is often built of insulating materials to withstand high voltages.

- The rotor, being a moving part, is designed for low inertia to reduce the load on the motor and increase efficiency.

- The stator, on the other hand, is designed to handle high voltages without breaking down, which requires the use of high-quality insulating materials.

Challenges in constructing these motors involve managing the high electrostatic fields without causing dielectric breakdowns. Moreover, managing leakage currents and achieving efficient charge transfer are essential for the reliable operation of these motors.

Applications of Electrostatic Motors

Electrostatic motors have been used in a range of applications due to their unique characteristics. These motors are inherently quiet, produce no electromagnetic interference, and can operate efficiently in a vacuum. This makes them particularly useful in space applications, like powering satellites or space rovers.

Advantages and Limitations

One significant advantage of electrostatic motors is their ability to operate in vacuum environments, making them ideal for space and high-altitude applications. In addition, these motors are remarkably quiet and produce no electromagnetic interference, which is beneficial in sensitive environments.

- They are also energy-efficient, as they have no iron losses and exhibit a high power-to-weight ratio.

- The lack of moving parts reduces wear and tear, resulting in lower maintenance requirements.

However, electrostatic motors also have their limitations. One primary drawback is the high voltages required for operation, which necessitates careful insulation and poses safety concerns. Also, these motors typically produce lower torque than electromagnetic motors and thus may not be suitable for heavy-duty applications.

Future Prospects

Despite their limitations, there is ongoing research to improve electrostatic motor technology. The focus is mainly on increasing their power and efficiency, reducing the operating voltage, and developing safer designs. With advancements in materials science, particularly in the development of superior insulating materials, there is potential for significant improvements in the performance and safety of these motors.

Emerging applications in nanotechnology also open new opportunities for electrostatic motors. Their compact design and high efficiency make them an excellent choice for powering nanoscale devices.

Conclusion

In conclusion, electrostatic motors offer a compelling alternative to traditional electric motors. While they currently face limitations such as high operating voltages and lower torque, ongoing research and technological advancements promise a bright future for this technology. Their unique advantages, such as the ability to operate in vacuum environments and the absence of electromagnetic interference, make them highly desirable for specific applications like space exploration and nanotechnology. With continued development, these motors are poised to play a vital role in various sectors, opening new avenues for innovation in the realm of electric machines.