Electrostatic field separators utilize electric fields to separate materials based on electrical properties, aiding in mineral processing, recycling, and waste management.

Electrostatic Field Separator: An Introduction

Overview of Electrostatic Separation Technology

Electrostatic separation is a widely used technology in various industries for the separation and purification of different materials. It harnesses the principle of electrostatic forces to differentiate between materials based on their electrical conductivity, permittivity, and other properties. Electrostatic field separators have found applications in multiple sectors, including mineral processing, recycling, and waste management.

How Electrostatic Field Separators Work

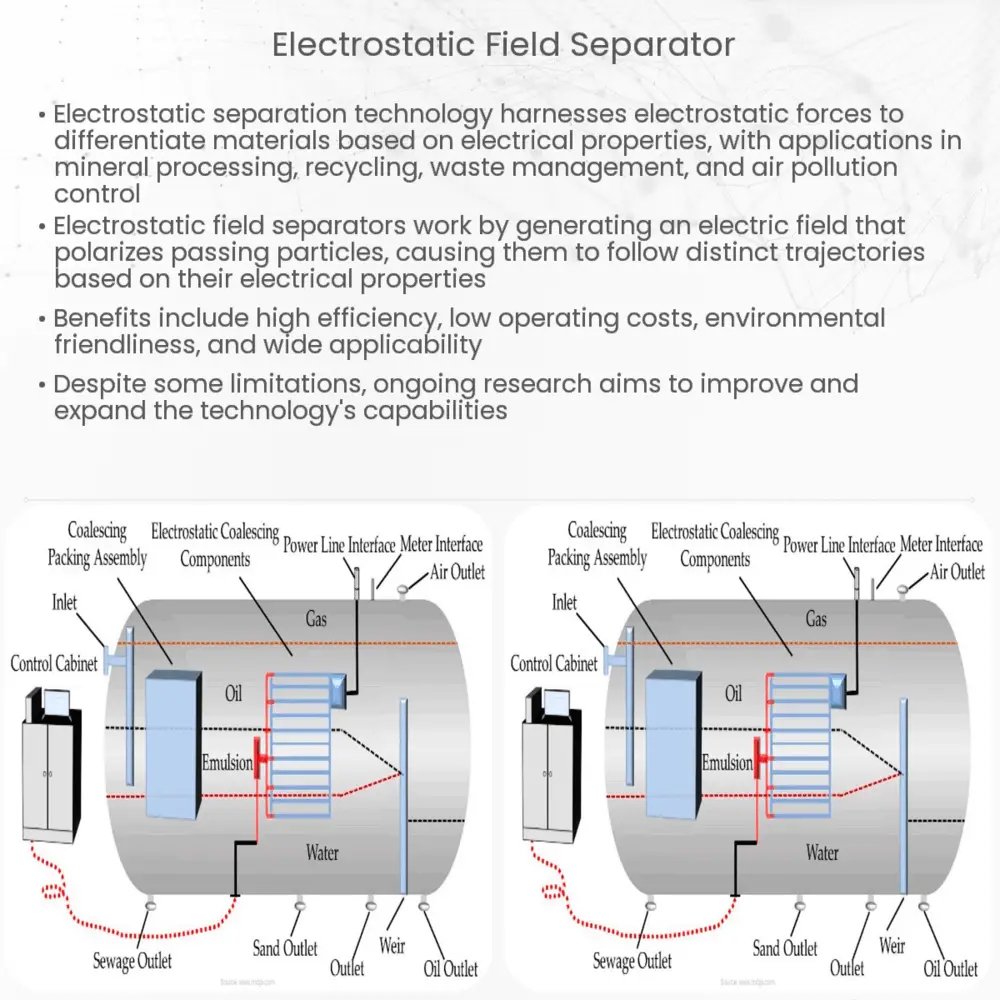

Electrostatic field separators function by generating an electric field between two oppositely charged electrodes. When the particles of materials pass through this electric field, they become polarized and develop an electrostatic charge. As a result, the charged particles experience a force that drives them towards the oppositely charged electrode. Consequently, particles with different electrical properties follow distinct trajectories, enabling their efficient separation.

There are two primary configurations of electrostatic field separators: the plate separator and the drum separator. Plate separators have a series of parallel conductive plates that create an electric field between them. In contrast, drum separators comprise a rotating conductive drum and a stationary electrode. The choice between these configurations depends on the specific application and the properties of the materials being separated.

Applications of Electrostatic Field Separators

Electrostatic field separators have a wide range of applications across various industries. Some of the most prominent examples include:

- Mineral Processing: In the mining industry, electrostatic separation is employed to separate valuable minerals from the gangue. This method is particularly effective for dry, granular materials and has been used to separate minerals like zircon, rutile, and ilmenite from their associated impurities.

- Recycling: Electrostatic field separators play a crucial role in recycling processes, where they help separate different types of materials, such as plastics and metals, from mixed waste streams. They are also used to recover valuable metals like copper and aluminum from electronic waste.

- Waste Management: In the waste management sector, electrostatic field separators can separate organic materials from inorganic waste, enabling more efficient recycling and disposal processes.

- Air Pollution Control: Electrostatic precipitators, a variation of electrostatic field separators, are used in industrial processes to remove particulate matter and dust from exhaust gas streams, thus reducing air pollution.

Advantages of Electrostatic Field Separators

Electrostatic field separators offer several advantages over other separation techniques. Some of the key benefits include:

- High separation efficiency: Electrostatic field separators can achieve high separation efficiency, even for materials with similar physical properties.

- Low operating costs: As they don’t involve the use of consumables like chemicals or water, these separators have lower operating costs compared to other separation methods.

- Environmentally friendly: The absence of chemicals and reduced water usage make electrostatic field separators an environmentally friendly choice for material separation.

- Wide applicability: Electrostatic separation is suitable for a variety of materials, making it a versatile separation technique.

Limitations of Electrostatic Field Separators

Despite their numerous advantages, electrostatic field separators also have some limitations:

- Material limitations: Electrostatic separation is most effective for dry, granular materials. Wet or sticky materials can cause complications in the separation process and reduce efficiency.

- Sensitivity to particle size: The efficiency of electrostatic field separators can be affected by variations in particle size. For optimal performance, materials must be carefully prepared and classified to ensure uniform particle size distribution.

- Conductivity requirements: The effectiveness of electrostatic field separators depends on the differences in electrical properties between the materials being separated. In cases where the materials have similar electrical properties, the separation efficiency may be compromised.

Improvements and Future Developments

Researchers and engineers are continuously working on improving electrostatic separation technology to overcome its limitations and expand its applications. Some of the ongoing efforts include:

- Developing advanced electrode designs and configurations to enhance the electric field and improve separation efficiency.

- Investigating the use of artificial intelligence and machine learning algorithms to optimize separation processes and reduce the influence of particle size variations.

- Exploring novel materials and surface treatments for electrodes to minimize fouling and improve durability.

- Studying the potential for integrating electrostatic field separators with other separation techniques, such as magnetic separation and flotation, to achieve more efficient and comprehensive separation processes.

Conclusion

Electrostatic field separators are a versatile and environmentally friendly separation technology with applications across various industries, including mineral processing, recycling, waste management, and air pollution control. By leveraging the principles of electrostatic forces, these separators can effectively separate materials based on their electrical properties. Despite some limitations, ongoing research and development efforts are paving the way for improved electrostatic separation techniques, offering the potential for even more efficient and cost-effective solutions in the future.