An electromechanical relay is a switch that uses an electromagnetic coil to open or close electrical contacts, providing control and isolation in various systems.

Electromechanical Relay: The Backbone of Modern Control Systems

Introduction

Electromechanical relays are a vital component in various industries, playing a significant role in the operation of modern control systems. These devices, which are used to control electrical circuits by opening or closing contacts, have been in use for over a century. Despite the advent of solid-state relays, electromechanical relays continue to be popular due to their simplicity, reliability, and cost-effectiveness. This article aims to provide an in-depth understanding of electromechanical relays, their working principles, and applications.

What is an Electromechanical Relay?

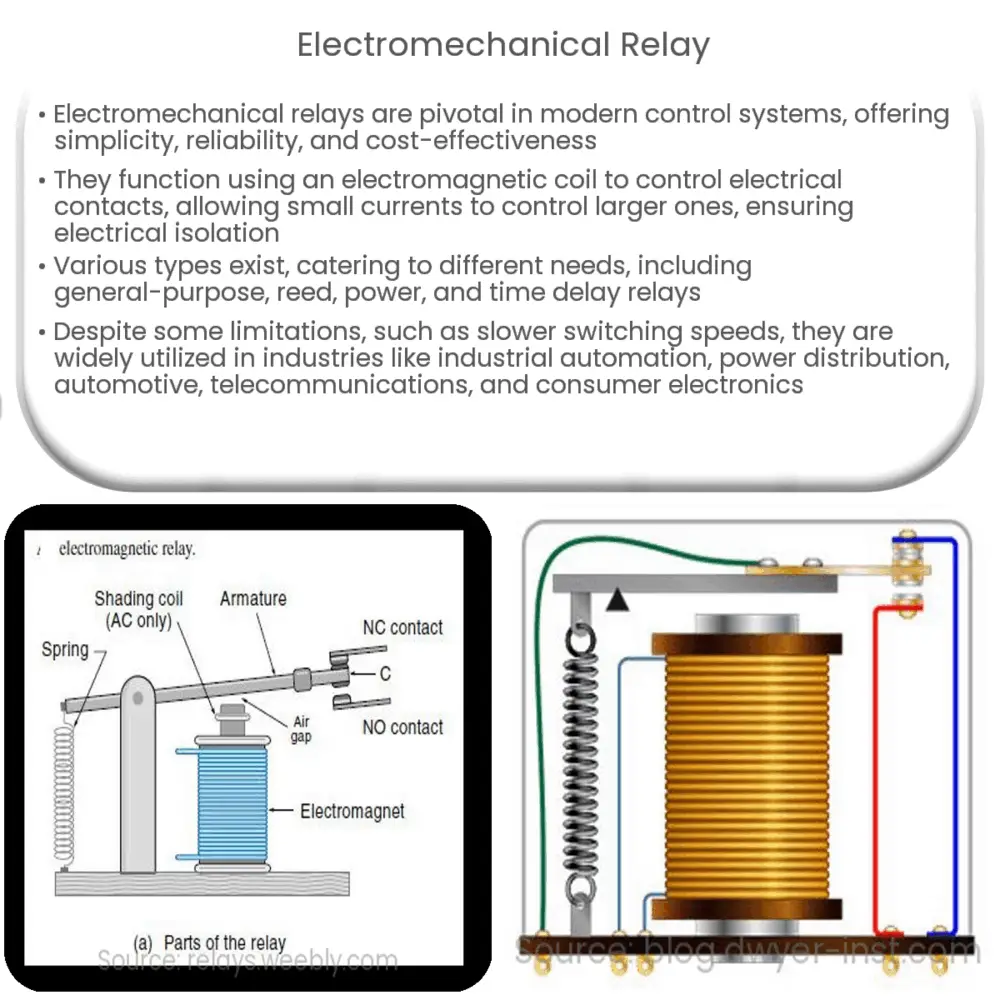

An electromechanical relay is a switch that uses an electromagnetic coil to control the opening and closing of electrical contacts. The relay consists of an electromagnet, an armature, and one or more sets of contacts. When an electrical current flows through the coil, a magnetic field is generated, which attracts the armature and causes the contacts to open or close. This mechanism allows a relatively small current to control a larger current or voltage, providing electrical isolation between the input and output circuits.

Working Principle of Electromechanical Relays

The working principle of an electromechanical relay can be divided into three main stages:

- Activation: When an electrical current is applied to the relay’s coil, a magnetic field is generated. This magnetic field attracts the armature, causing it to move towards the coil.

- Movement: The movement of the armature changes the position of the contacts, either opening or closing the electrical circuit.

- Deactivation: When the current flowing through the coil is removed, the magnetic field disappears, and the armature returns to its original position due to the spring force. This action reverts the contacts to their initial state.

Types of Electromechanical Relays

Electromechanical relays can be classified into various types based on their structure, operation, and application. Some common types include:

- General Purpose Relays: These are the most common type of electromechanical relays and are used in a wide range of applications. They typically have multiple contacts and can handle a variety of voltages and currents.

- Reed Relays: Reed relays consist of two or more reed switches sealed in a glass tube. They offer fast switching times and are used in applications requiring low power consumption and high speed.

- Power Relays: Power relays are designed to handle higher voltages and currents. They are used in applications such as motor control and high-power switching.

- Time Delay Relays: These relays incorporate a timer circuit that delays the opening or closing of the contacts for a specific period. They are used in applications requiring time-based control, such as industrial automation and process control.

Advantages and Disadvantages of Electromechanical Relays

Electromechanical relays offer several advantages and disadvantages compared to other switching technologies, such as solid-state relays:

Advantages

- Electrical Isolation: Electromechanical relays provide excellent electrical isolation between input and output circuits, protecting sensitive electronic components from potential damage.

- Cost-Effectiveness: They are generally less expensive than solid-state relays, making them a popular choice for budget-conscious applications.

- Reliability: Due to their simple construction and minimal component count, electromechanical relays are highly reliable and have a long operational life.

- Noise Immunity: These relays are less susceptible to electromagnetic interference, making them suitable for use in electrically noisy environments.

Disadvantages

- Switching Speed: Electromechanical relays have slower switching times compared to solid-state relays, limiting their use in high-speed applications.

- Mechanical Wear: The mechanical nature of electromechanical relays can lead to wear and tear over time, reducing their lifespan compared to solid-state alternatives.

- Power Consumption: The power required to operate the coil can be relatively high, especially for larger relays, which may be a concern in energy-sensitive applications.

Applications of Electromechanical Relays

Electromechanical relays are widely used in various industries and applications, including:

- Industrial Automation: Relays are used in control panels, motor starters, and other automation equipment to control and protect electrical devices.

- Power Distribution: They play a crucial role in power distribution systems, helping to manage and protect electrical circuits in residential, commercial, and industrial settings.

- Automotive: Electromechanical relays are used in vehicles for controlling various electrical systems, such as lighting, power windows, and engine control modules.

- Telecommunications: Relays are employed in telephone exchanges and other communication equipment for switching and signal routing.

- Consumer Electronics: They can be found in household appliances, such as washing machines, air conditioners, and refrigerators, to control electrical circuits and ensure safe operation.

Conclusion

Despite the emergence of solid-state alternatives, electromechanical relays continue to be a popular choice in various industries due to their simplicity, reliability, and cost-effectiveness. They play a crucial role in modern control systems and are widely used across a range of applications. Understanding the working principles, types, advantages, and disadvantages of electromechanical relays is essential for engineers, technicians, and hobbyists working with electrical and electronic systems.