An electromagnetic pressure sensor measures pressure by converting magnetic field changes into electrical signals, offering high sensitivity and accuracy.

Electromagnetic Pressure Sensor: An Overview

Introduction

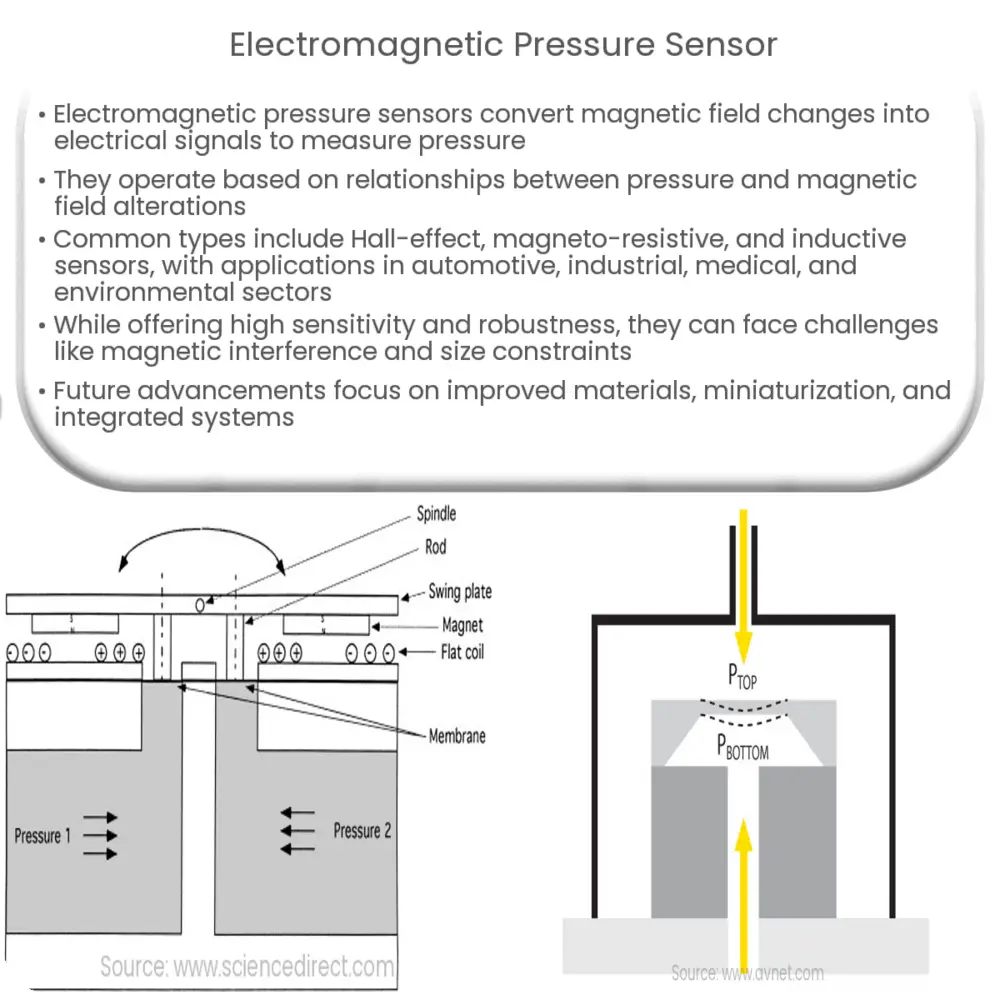

Electromagnetic pressure sensors are versatile devices that play a crucial role in various applications, from automotive systems to industrial machinery. These sensors measure pressure by converting changes in magnetic fields into electrical signals. This article provides an introduction to electromagnetic pressure sensors, explaining their principles of operation, types, and applications.

Principles of Operation

The basic principle of an electromagnetic pressure sensor relies on the relationship between pressure and magnetic field changes. When pressure is applied to a sensing element containing a magnetic material, the material’s magnetic properties are altered. This change in the magnetic field is then detected by a magnetic sensor, such as a Hall-effect sensor or a magneto-resistive sensor. The sensor converts the change in the magnetic field into an electrical signal, which is then processed and interpreted by a microcontroller or a signal conditioning circuit to determine the corresponding pressure value.

Types of Electromagnetic Pressure Sensors

There are several types of electromagnetic pressure sensors, each with its own advantages and applications. Some of the most common types include:

- Hall-effect Pressure Sensors: These sensors utilize the Hall effect, a phenomenon in which a voltage is generated in a conductor when it is exposed to a magnetic field perpendicular to the direction of the current flow. Hall-effect pressure sensors are known for their high sensitivity and accuracy, making them ideal for various applications, such as automotive systems and industrial processes.

- Magneto-resistive Pressure Sensors: These sensors operate based on the magneto-resistive effect, in which the electrical resistance of a material changes in response to an applied magnetic field. Magneto-resistive pressure sensors are highly sensitive and can measure small pressure changes, making them suitable for applications like medical devices and precision instrumentation.

- Inductive Pressure Sensors: Inductive pressure sensors work by detecting changes in the inductance of a coil due to pressure-induced changes in the magnetic field. These sensors are robust and can handle high-pressure environments, making them suitable for applications in heavy machinery and hydraulic systems.

Applications of Electromagnetic Pressure Sensors

Electromagnetic pressure sensors find use in a wide range of industries and applications, including:

- Automotive systems: monitoring tire pressure, fuel injection, and brake systems

- Industrial processes: controlling and monitoring pressure in hydraulic systems, pipelines, and process control systems

- Medical devices: monitoring blood pressure, respiratory systems, and infusion pumps

- Environmental monitoring: measuring water levels, atmospheric pressure, and wind speed

In the next section, we will explore the advantages of electromagnetic pressure sensors, their limitations, and the future of this technology.

Advantages of Electromagnetic Pressure Sensors

Electromagnetic pressure sensors offer several advantages compared to other pressure sensing technologies, such as:

- High sensitivity and accuracy: Due to their reliance on magnetic field changes, these sensors can accurately measure even the smallest pressure changes, making them ideal for precise applications.

- Wide operating range: Electromagnetic pressure sensors can operate over a wide range of pressures, enabling their use in various environments and applications.

- Robustness: These sensors are less affected by environmental factors such as temperature, humidity, and vibration, ensuring reliable performance in harsh conditions.

- Low power consumption: Electromagnetic pressure sensors typically consume less power than other sensing technologies, making them suitable for battery-powered devices and energy-efficient applications.

Limitations of Electromagnetic Pressure Sensors

Despite their advantages, electromagnetic pressure sensors also have some limitations:

- Magnetic interference: The presence of strong external magnetic fields can interfere with the sensor’s performance, leading to inaccurate readings. Proper shielding and calibration are essential to mitigate this issue.

- Size constraints: The size of the magnetic sensing elements can limit the miniaturization potential of these sensors, making it difficult to integrate them into certain applications with space constraints.

- Cost: Electromagnetic pressure sensors can be more expensive than other types of pressure sensors, particularly for high-precision and high-temperature applications.

Future of Electromagnetic Pressure Sensors

The future of electromagnetic pressure sensors is promising, with continuous advancements in materials science, sensor design, and manufacturing techniques leading to improved performance and new applications. Some potential developments in the field include:

- Improved materials: The development of new magnetic materials with enhanced properties, such as higher sensitivity and better temperature stability, can lead to more accurate and reliable sensors.

- Miniaturization: Advances in microfabrication and nanotechnology can enable the creation of smaller sensors, opening up new applications in areas such as wearable devices and medical implants.

- Integrated systems: The integration of electromagnetic pressure sensors with other sensing technologies, such as temperature and humidity sensors, can lead to more versatile and intelligent sensing systems for various applications.

- Wireless and energy harvesting: The development of wireless communication and energy harvesting technologies can enable self-powered and remotely monitored pressure sensing systems, reducing the need for batteries and wired connections.

In conclusion, electromagnetic pressure sensors play a vital role in various industries and applications due to their high sensitivity, accuracy, and robustness. Despite some limitations, ongoing advancements in materials and technology promise to further improve their performance and expand their range of applications.