Eddy current proximity sensors detect distance & displacement with high accuracy in harsh environments, ideal for automation, aerospace, and more.

Eddy Current Proximity Sensor: A Comprehensive Overview

Introduction

Eddy current proximity sensors are a critical component in numerous applications, playing an essential role in industrial automation, transportation, and other sectors. These sensors are known for their ability to provide accurate and reliable measurements of proximity or displacement, even in harsh environments. In this article, we will discuss the principles behind eddy current proximity sensors, their advantages, and their applications.

Principles of Eddy Current Proximity Sensors

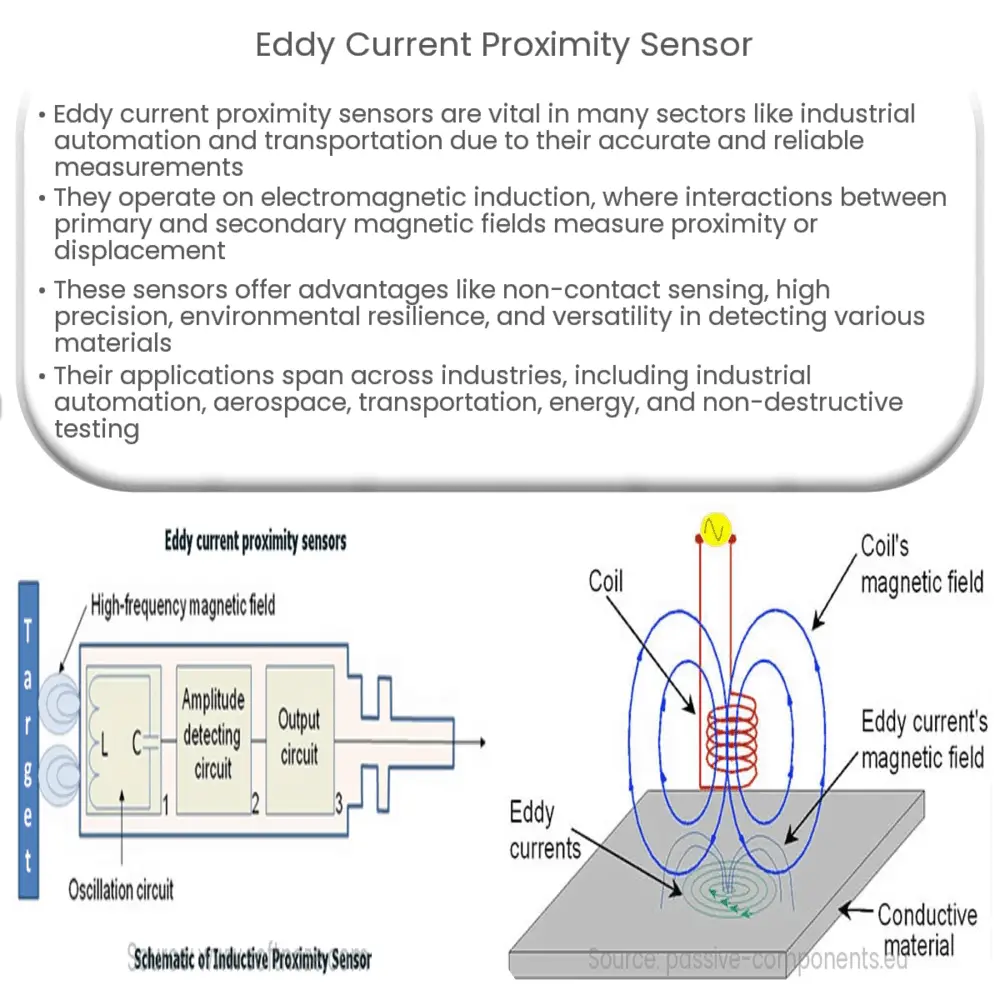

Eddy current proximity sensors operate based on the principle of electromagnetic induction. The sensor consists of a coil that generates an alternating magnetic field when an alternating current (AC) flows through it. This magnetic field interacts with any conductive material, such as a metal target, in the vicinity of the sensor. As a result, eddy currents are induced within the target material, producing a secondary magnetic field that opposes the primary magnetic field of the coil.

The interaction between the primary and secondary magnetic fields causes a change in the impedance of the coil. This impedance change is directly proportional to the distance between the sensor and the target, allowing the sensor to measure the proximity or displacement of the target accurately. A signal processing circuit within the sensor converts the impedance change into an output signal, such as voltage or current, that can be easily interpreted by other systems or devices.

Advantages of Eddy Current Proximity Sensors

Eddy current proximity sensors offer several advantages over other types of proximity sensors, such as inductive, capacitive, or ultrasonic sensors. Some of the key benefits include:

- Non-contact sensing: Eddy current sensors can measure proximity or displacement without requiring physical contact with the target, reducing wear and tear on both the sensor and the target.

- High accuracy and resolution: These sensors are known for their high accuracy and resolution, often in the order of micrometers, making them suitable for various precision measurement applications.

- Immunity to environmental factors: Eddy current sensors are not affected by dust, dirt, oil, or other contaminants, making them suitable for use in harsh industrial environments. They are also insensitive to changes in temperature, humidity, and pressure.

- Material versatility: While eddy current sensors are most commonly used for sensing metallic targets, they can also detect non-metallic materials with conductive properties, such as carbon fiber composites or certain types of plastics.

In the next part of this article, we will explore the various applications of eddy current proximity sensors in different industries and discuss their role in ensuring the safety, efficiency, and reliability of various processes and systems.

Applications of Eddy Current Proximity Sensors

Eddy current proximity sensors find widespread use in various industries due to their unique capabilities and advantages. Some of the most common applications include:

- Industrial automation: These sensors are widely used for position and displacement measurement in automated manufacturing processes, such as assembly lines, robotic systems, and CNC machines. They ensure precision and control in applications like tool wear monitoring, quality control, and part sorting.

- Aerospace and defense: Eddy current sensors are used in aircraft systems for monitoring critical components, such as turbine engines, landing gear, and structural health. They can detect minute changes in material properties, enabling early detection of potential issues and preventing catastrophic failures.

- Transportation: In the automotive industry, eddy current sensors are employed for measuring shaft speed, wheel speed, and bearing wear in vehicles. They also play a crucial role in railway systems, where they are used for track inspection, wheelset monitoring, and train speed detection.

- Energy: Eddy current sensors are used in the power generation sector for monitoring components like steam turbines, generators, and pumps. They help ensure optimal performance and prevent unexpected downtime in power plants.

- Non-destructive testing (NDT): These sensors are used for non-destructive testing of materials and structures, including flaw detection, crack propagation monitoring, and corrosion inspection. Their high sensitivity and accuracy make them ideal for detecting defects in critical structures, such as bridges, pipelines, and aircraft components.

Conclusion

Eddy current proximity sensors are a versatile and robust sensing technology that offers numerous benefits over other sensing methods. Their non-contact operation, high accuracy and resolution, immunity to environmental factors, and material versatility make them a popular choice for a wide range of industries and applications. As technology continues to evolve and the demand for precision and reliability increases, eddy current sensors will undoubtedly continue to play a critical role in shaping the future of various sectors, ensuring safety, efficiency, and overall system reliability.