Optical proximity sensors use light to measure distance or presence of objects with high precision, benefiting various industries and applications.

Optical Proximity Sensors: How They Work and Their Applications

Introduction

Optical proximity sensors are a vital component in many industrial and consumer applications, providing a non-contact solution to measure the distance or presence of an object. These sensors use light to determine the proximity of an object, making them a popular choice for applications that require precision and reliability. In this article, we will explore the working principles of optical proximity sensors, their types, and their applications in various industries.

Working Principle of Optical Proximity Sensors

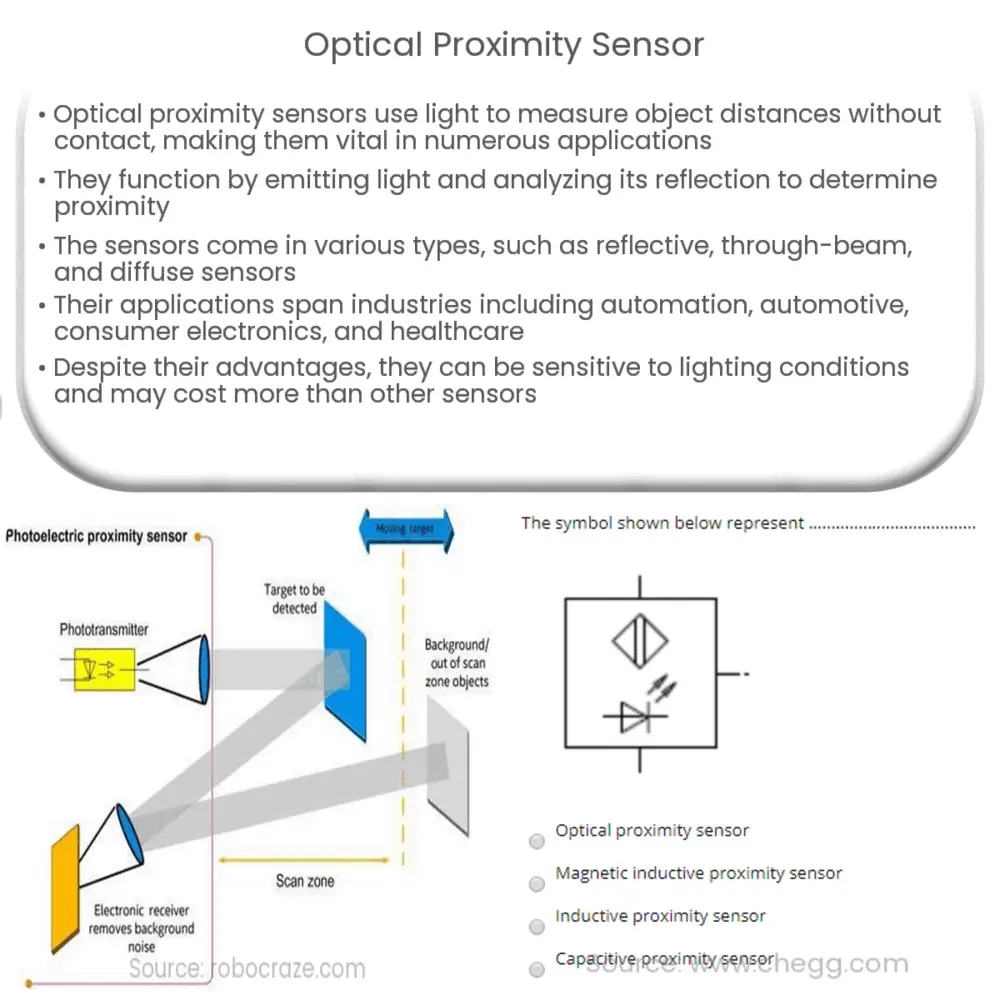

Optical proximity sensors operate by emitting a beam of light, usually infrared, and measuring the intensity of the reflected light to determine the distance to the object. The sensor consists of two main components: an emitter, which generates the light, and a detector, which senses the reflected light. When an object is close to the sensor, the intensity of the reflected light is high, and when the object is far away, the intensity is low. By analyzing the intensity of the reflected light, the sensor can calculate the distance to the object.

There are two primary methods used in optical proximity sensing: time-of-flight (ToF) and triangulation. ToF sensors measure the time it takes for the emitted light to travel to the object and back, while triangulation sensors measure the angle between the emitted and reflected light. Both methods have their advantages and drawbacks, with ToF sensors typically offering longer sensing ranges and triangulation sensors providing higher resolution and accuracy.

Types of Optical Proximity Sensors

There are several types of optical proximity sensors, each with its unique characteristics and advantages. Some of the most common types include:

- Reflective Sensors: Reflective sensors rely on the reflection of emitted light from the surface of the object. These sensors are the simplest and most widely used type of optical proximity sensor. They are suitable for detecting objects with reflective surfaces, but their performance can be affected by the object’s color and surface finish.

- Through-beam Sensors: Through-beam sensors consist of a separate emitter and detector, which are placed opposite each other. The presence of an object is detected when it interrupts the beam of light between the emitter and detector. Through-beam sensors offer high accuracy and longer sensing ranges but require precise alignment of the emitter and detector.

- Diffuse Sensors: Diffuse sensors combine the emitter and detector in a single unit, like reflective sensors. However, they use a different principle for detecting objects, relying on the diffusion of light rather than reflection. Diffuse sensors can detect objects with non-reflective surfaces but have a shorter sensing range compared to through-beam sensors.

Applications of Optical Proximity Sensors

Optical proximity sensors have a wide range of applications across various industries, such as:

- Automation and Robotics: Proximity sensors are commonly used in automated assembly lines and robotic systems for tasks like object detection, positioning, and collision avoidance.

- Automotive: In the automotive industry, optical proximity sensors are used for applications like parking assistance systems, blind-spot detection, and vehicle proximity warning systems.

- Consumer Electronics: Optical proximity sensors are found in many consumer electronics devices, including smartphones, where they are used to detect the presence of a user’s ear during a call, and in touchless control systems for gesture recognition.

- Medical and Healthcare: In medical devices and healthcare systems, optical proximity sensors play a critical role in ensuring patient safety and proper equipment function. Applications include monitoring intravenous drip rates, detecting the presence of medical instruments, and ensuring correct positioning of patients during diagnostic procedures.

- Security and Surveillance: Optical proximity sensors are employed in security systems for perimeter monitoring, intrusion detection, and access control. They can be used to detect the presence of people or objects, monitor restricted areas, and trigger alarms in case of unauthorized entry.

- Agriculture and Farming: In the agriculture sector, optical proximity sensors are utilized for tasks such as crop monitoring, soil analysis, and automated harvesting. They can help farmers optimize irrigation, detect plant health issues, and improve overall crop yield.

Advantages and Disadvantages of Optical Proximity Sensors

Optical proximity sensors offer several advantages over other types of proximity sensors, such as inductive or capacitive sensors. Some of these advantages include:

- Non-contact sensing: Optical sensors can detect objects without physical contact, reducing the risk of damage or wear to the sensor and the object.

- High precision and accuracy: Optical sensors can provide precise distance measurements, making them suitable for applications that require high levels of accuracy.

- Ability to detect a wide range of materials: Unlike inductive or capacitive sensors, which are limited to detecting specific materials, optical sensors can detect almost any object, regardless of its composition.

- Insensitive to environmental factors: Optical sensors are less affected by factors like temperature, humidity, or the presence of dust or dirt, making them suitable for use in harsh environments.

However, optical proximity sensors also have some disadvantages:

- Sensitivity to light conditions: Ambient light or changes in lighting conditions can interfere with the sensor’s operation, leading to false readings or reduced accuracy.

- Limitations with certain object properties: The performance of optical sensors can be affected by the object’s color, transparency, or surface finish, which may lead to inconsistent readings.

- Higher cost: Optical proximity sensors are generally more expensive than other types of sensors due to their complexity and precision.

Conclusion

Optical proximity sensors are a versatile and reliable solution for various distance measurement and object detection applications. They offer numerous advantages over other types of proximity sensors and have a wide range of applications across different industries. Despite some limitations, their accuracy, flexibility, and non-contact sensing capabilities make them a popular choice for many industrial and consumer applications.