A dew point hygrometer measures the temperature at which air becomes saturated, helping control humidity in various industries and applications.

Dew Point Hygrometer: Principles and Applications

Introduction

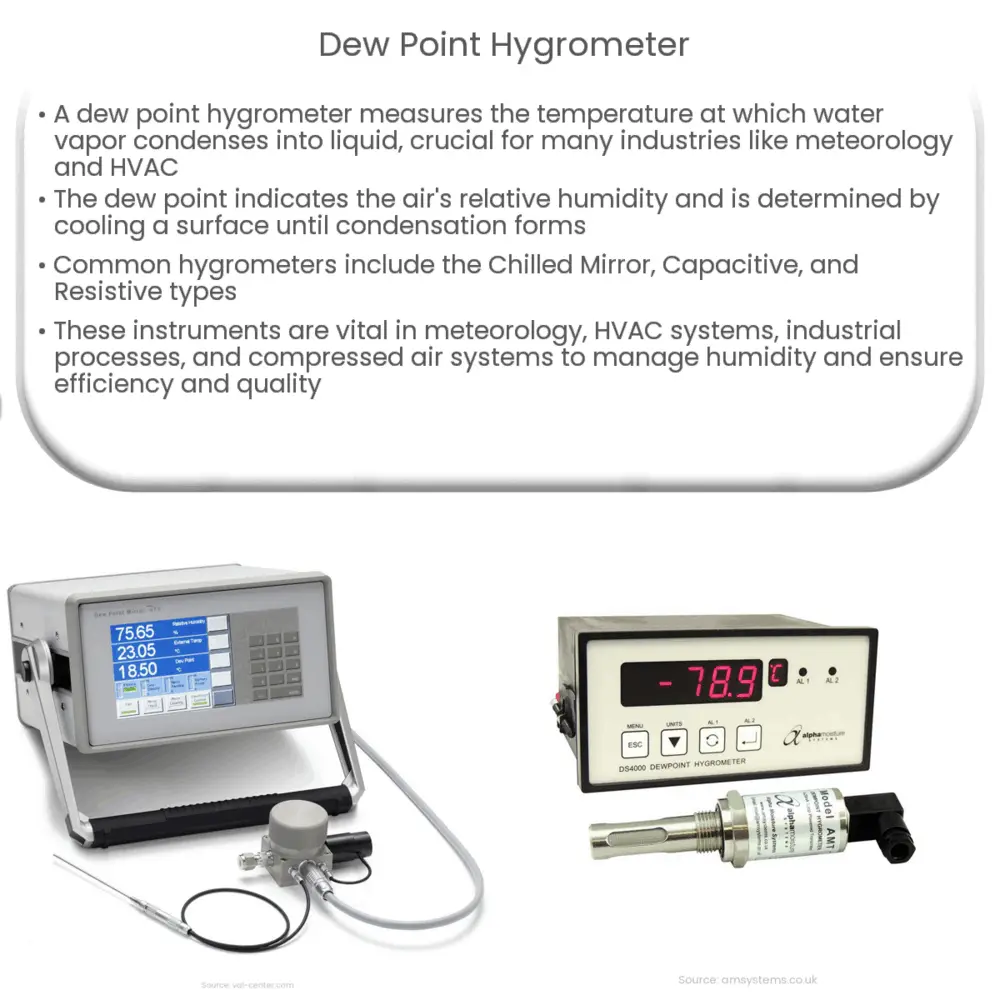

A dew point hygrometer is a critical instrument used to measure the dew point temperature of a gas, which is the temperature at which water vapor in the gas begins to condense into liquid. This measurement is essential for various industries such as meteorology, HVAC systems, and manufacturing processes that require strict control of humidity levels. In this article, we will discuss the basic principles behind dew point hygrometers, the types of hygrometers available, and their applications.

Principles of Dew Point Measurement

The dew point is the temperature at which air becomes saturated with water vapor, and condensation begins to occur. When air cools, its capacity to hold water vapor decreases. As the air temperature decreases, the water vapor in the air eventually reaches a saturation point, and excess water vapor condenses into liquid droplets. The dew point is an important parameter in determining the relative humidity of the air, as it is directly related to the amount of water vapor present in the air.

Dew point hygrometers measure the dew point by cooling a surface, typically a mirror, to the point where condensation starts to form. The temperature of the surface at the onset of condensation is recorded as the dew point temperature. This method is based on the fact that the dew point is the temperature at which the saturation vapor pressure of the water vapor in the air equals the actual vapor pressure.

Types of Dew Point Hygrometers

There are several types of dew point hygrometers, each with their own advantages and disadvantages. Some of the most common types include:

- Chilled Mirror Hygrometer: This is the most accurate type of dew point hygrometer, using a cooled mirror to determine the dew point. A light source is directed at the mirror, and a detector measures the intensity of the reflected light. As condensation forms on the mirror, the intensity of the reflected light decreases, and the temperature of the mirror is recorded as the dew point.

- Capacitive Hygrometer: Capacitive hygrometers measure the dew point by monitoring changes in the capacitance of a sensor as the relative humidity changes. The sensor is typically made of a polymer film or a ceramic material that absorbs moisture from the air, causing a change in the electrical capacitance. The change in capacitance is then converted into a dew point temperature.

- Resistive Hygrometer: These hygrometers measure the dew point by detecting changes in the electrical resistance of a humidity-sensitive material, such as a polymer or metal oxide. As the humidity increases, the resistance of the material changes, and this change is used to calculate the dew point temperature.

Applications of Dew Point Hygrometers

Dew point hygrometers are essential in various industries and applications where accurate humidity control and measurement are crucial. Some of the key applications include:

- Meteorology: Meteorologists use dew point hygrometers to measure the atmospheric dew point and relative humidity, which are essential parameters for weather forecasting and climate studies. Dew point data helps predict the formation of fog, frost, and dew, as well as the likelihood of precipitation.

- HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, dew point hygrometers are used to maintain optimal humidity levels for occupant comfort and to prevent condensation on surfaces, which can lead to mold growth and structural damage. Proper humidity control can also improve energy efficiency by reducing the need for additional heating or cooling.

- Industrial Processes: Manufacturing processes in industries such as pharmaceuticals, electronics, and food and beverages often require strict humidity control to ensure product quality and safety. Dew point hygrometers help monitor and control humidity levels in production areas, cleanrooms, and storage facilities.

- Compressed Air Systems: Dew point measurement is essential in compressed air systems to prevent condensation and corrosion within the system. Excessive moisture can cause damage to pneumatic tools and equipment, contaminate products, and compromise system efficiency. Dew point hygrometers help maintain the optimal level of dryness in compressed air systems.

Conclusion

Dew point hygrometers play a vital role in maintaining and monitoring humidity levels in various applications across multiple industries. Understanding the principles behind dew point measurement and the different types of hygrometers available is essential in selecting the right instrument for a specific application. By accurately measuring the dew point, industries can ensure product quality, system efficiency, and occupant comfort while minimizing the risk of damage due to excessive moisture and condensation.