Explore the functions, applications, types, and maintenance of conductance meters, and delve into advancements shaping their future.

Understanding Conductance Meters

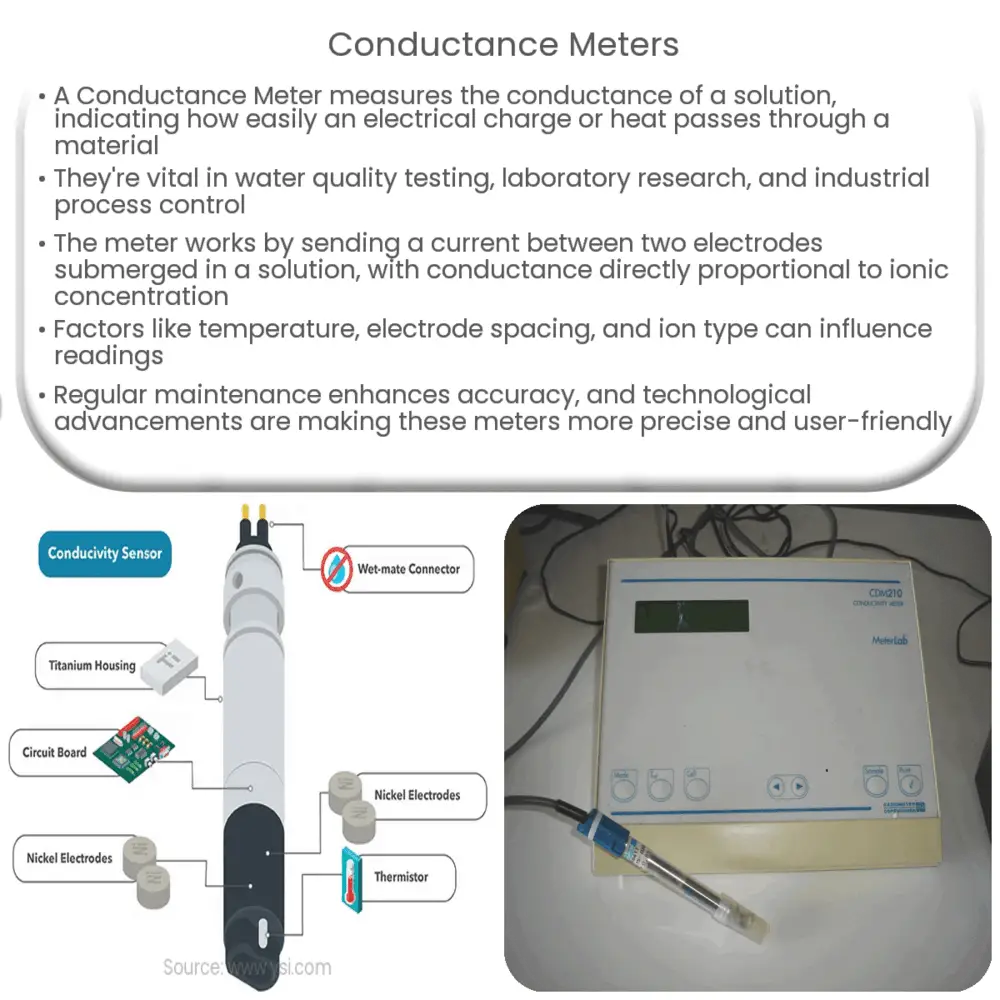

A Conductance Meter is a device that is used extensively in several industrial and laboratory applications. This piece of equipment primarily measures the conductance of a solution, which is the reciprocal of resistance. In simpler terms, conductance is the measure of how easily an electrical charge or heat can pass through a material.

Applications of Conductance Meters

- Water Quality Testing: Conductance meters are a common sight in water treatment plants, where they measure the purity of the water. The device can quantify the level of salts or impurities present in the water, which affects its conductivity.

- Laboratory Use: In laboratory settings, these meters help in understanding the properties of different solutions and materials. They are pivotal in analytical chemistry, where they’re used to ascertain solution concentrations.

- Industrial Process Control: Conductance meters are also found in various industrial processes, where they serve to monitor and control process parameters. For instance, in metal plating, the solution’s conductance needs to be measured constantly for optimum results.

Working Principle of Conductance Meters

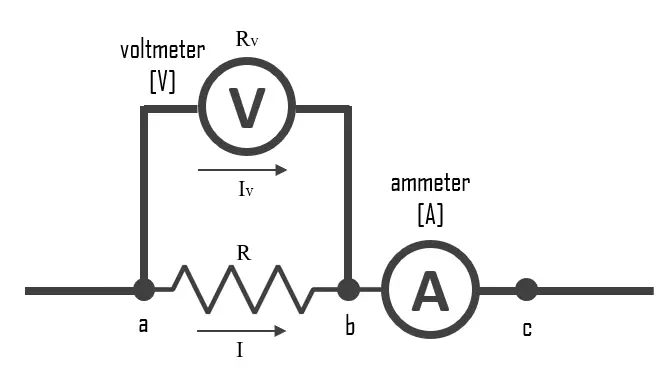

A conductance meter operates on a rather straightforward principle. It uses a probe or a pair of electrodes that are submerged into the solution to be tested. The meter then sends a small electrical current between these two electrodes. The ease with which this current flows through the solution, thus completing the circuit, determines the solution’s conductance.

It’s essential to note that the conductance is directly proportional to the ionic concentration in the solution. So, when the number of ions (charged particles) increases, so does the conductivity. This is due to the ions acting as carriers for the electrical charge, thereby facilitating its passage through the solution.

Types of Conductance Meters

- Benchtop Meters: These are large and highly accurate meters used primarily in laboratory environments.

- Portable Meters: These are lightweight, compact, and designed for field use. They’re less precise than benchtop meters, but their portability is a significant advantage.

Understanding the capabilities and limitations of each type of conductance meter is crucial when choosing a suitable device for specific needs.

Factors Influencing Conductance Measurements

When using a conductance meter, there are several factors to consider, as they can influence the accuracy of the readings. Here are a few:

- Temperature: Temperature plays a crucial role in conductivity measurements. The conductivity of a solution generally increases with temperature, and thus, it’s often necessary to perform measurements at a fixed temperature or use temperature compensation techniques.

- Electrode Spacing and Area: The distance between electrodes and their surface area can affect the measurement. In general, greater electrode areas and smaller spacing lead to higher conductance readings.

- Type and Concentration of Ions: Different ions have different mobilities, and thus, the type of ions in the solution can impact the conductance. Moreover, higher ion concentration usually results in higher conductivity.

Maintaining a Conductance Meter

Regular maintenance and calibration of a conductance meter are paramount for its continued precision and longevity. This process involves cleaning the electrode and recalibrating the device using standard solutions with known conductivity. Ensuring the electrodes are free from any adhering material and the meter is reading the standard solutions correctly can significantly enhance the reliability of the measurements.

Latest Developments

In the ever-evolving world of technology, conductance meters are also benefiting from new innovations and advancements. The integration of digital technology and improved materials has made these meters more precise, reliable, and user-friendly. Some modern conductance meters now come with digital displays, automatic temperature compensation, data logging, and even wireless connectivity for easier data transfer and monitoring.

Conclusion

In conclusion, a conductance meter is an indispensable tool in various sectors, from water treatment to industrial process control and laboratory research. Understanding its working principle, types, influencing factors, and maintenance practices can significantly enhance its effective use and the reliability of the readings. With ongoing advancements in technology, we can expect to see even more sophisticated and efficient conductance meters in the future, further propelling their applications and usefulness.