Braided wire is a flexible, durable conductor with low electrical resistance and EMI shielding, ideal for aerospace, automotive, medical, and telecommunications applications.

Braided Wire: An Introduction to Its Applications and Benefits

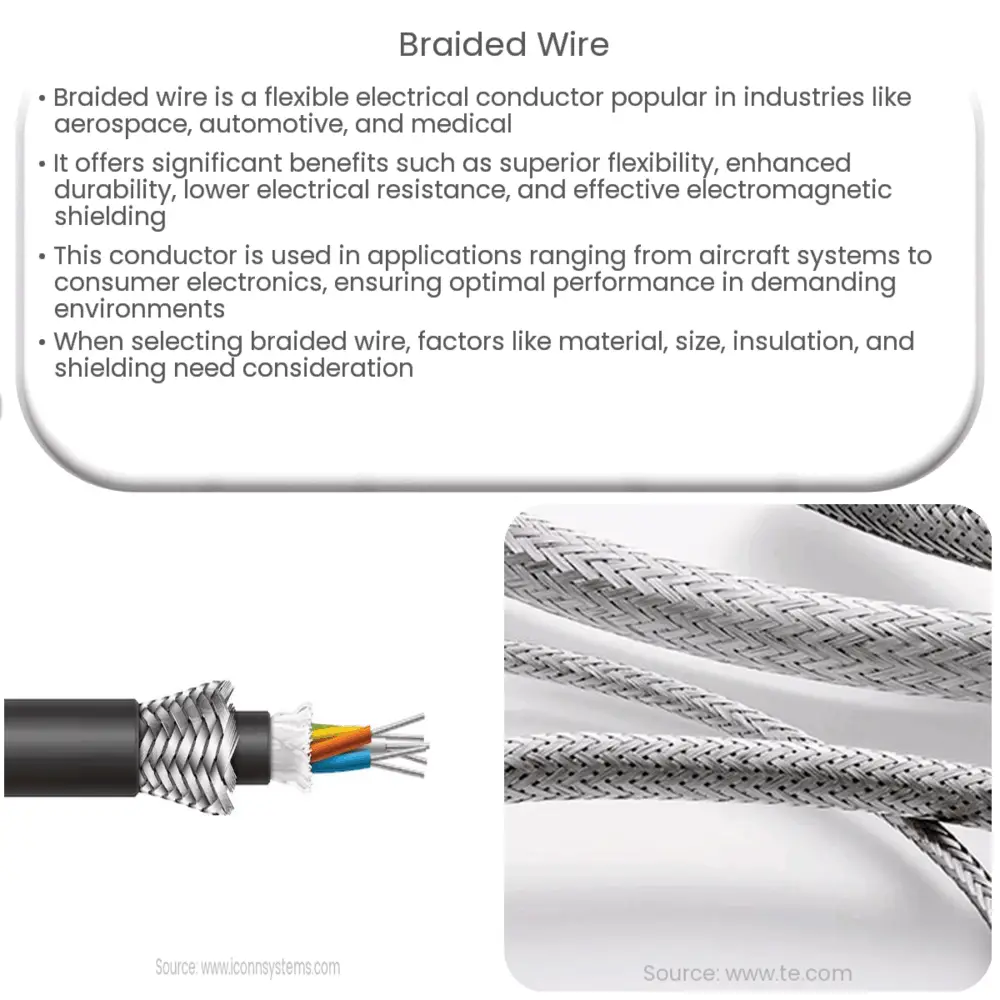

Braided wire is a type of electrical conductor made from multiple strands of thin wire woven or braided together. This versatile and flexible conductor is widely used in various industries, including aerospace, automotive, medical, telecommunications, and more. In this article, we will explore the benefits and applications of braided wire, and why it is preferred over other types of conductors in specific scenarios.

Benefits of Braided Wire

There are several reasons why braided wire is popular among engineers and designers. Some of the key benefits include:

- Flexibility: The woven design of braided wire allows for greater flexibility than solid or stranded wire, making it easier to bend and manipulate into the desired shape. This is particularly useful in applications where the wire needs to be routed through tight spaces or around sharp corners.

- Durability: The braided structure provides excellent mechanical protection, making the wire more resistant to abrasion, wear, and other environmental factors. This is important in applications where the wire is exposed to harsh conditions or repeated movement, such as in robotics or aerospace components.

- Lower electrical resistance: The increased surface area of the braided wire allows for better electrical conductivity, resulting in lower resistance compared to other types of conductors. This leads to better performance and lower energy losses, especially in high-frequency applications.

- Electromagnetic shielding: The braided construction can help reduce electromagnetic interference (EMI) by acting as a shield, minimizing the effects of external electrical noise on the wire’s signal transmission. This is essential in industries like telecommunications and medical equipment, where signal clarity and integrity are paramount.

Applications of Braided Wire

Braided wire has a wide range of applications across various industries, some of which include:

- Aerospace: In the aerospace industry, braided wire is used in wiring harnesses, ground straps, and shielding for avionics and other electronic systems. Its flexibility, durability, and EMI shielding capabilities make it an ideal choice for the demanding environments of aircraft and spacecraft.

- Automotive: Braided wire is used extensively in the automotive industry for battery cables, grounding straps, and other electrical systems. Its durability and flexibility allow it to withstand the vibration and temperature variations common in automotive applications.

- Medical: The medical industry relies on braided wire for various applications, including catheter reinforcement, surgical instruments, and medical device components. The flexibility, biocompatibility, and EMI shielding properties of braided wire make it suitable for these sensitive applications.

In conclusion, braided wire offers numerous advantages over other types of electrical conductors, making it a popular choice for a variety of industries and applications. Its flexibility, durability, and EMI shielding capabilities provide improved performance and longevity in demanding environments.

Telecommunications:

In the telecommunications industry, braided wire plays a crucial role in the construction of cables for data transmission and signal integrity. Its EMI shielding properties make it suitable for use in environments with high levels of interference, ensuring reliable communication and data transfer.

Consumer Electronics:

Braided wire is also found in a variety of consumer electronic devices, such as headphones, charging cables, and audio cables. Its durability and flexibility make it an ideal choice for these products, which often undergo regular bending and twisting during daily use.

Industrial Applications:

In industrial settings, braided wire is used for grounding and bonding electrical systems, as well as for shielding sensitive electronics from EMI. Its mechanical strength and resistance to abrasion make it suitable for use in harsh environments, such as manufacturing plants and heavy machinery applications.

Selecting the Right Braided Wire

When selecting braided wire for a specific application, it’s essential to consider several factors, including:

- Material: Braided wire can be made from various materials, such as copper, aluminum, stainless steel, and nickel. The choice of material will depend on factors like electrical conductivity, weight, and corrosion resistance, among others.

- Size: The size of the braided wire is determined by its overall diameter and the number of strands. This will affect the wire’s flexibility, strength, and electrical resistance. It is crucial to choose the appropriate size based on the application requirements.

- Insulation: In some cases, braided wire may require insulation to protect it from environmental factors or to prevent electrical shorts. Various insulation materials are available, such as PVC, silicone, and PTFE, each with its unique properties and temperature ratings.

- Shielding: Additional shielding may be necessary for applications that require enhanced EMI protection. Shielding materials, such as foil or additional braided layers, can be added to improve the wire’s overall EMI performance.

Conclusion

Braided wire is a versatile and reliable conductor that offers numerous benefits, including flexibility, durability, low electrical resistance, and EMI shielding capabilities. Its wide range of applications across industries such as aerospace, automotive, medical, telecommunications, consumer electronics, and industrial settings demonstrates its adaptability and effectiveness. By carefully considering the material, size, insulation, and shielding requirements, braided wire can be tailored to meet the specific demands of various applications, providing improved performance and longevity.