Explore barium strontium titanate (BST) as a ferroelectric material, its properties, applications, challenges, and future research directions.

Barium Strontium Titanate (BST) as Ferroelectric Material: An Overview

Introduction

Barium strontium titanate (BST) is a mixed oxide compound with the general formula Ba1-xSrxTiO3, where x can vary between 0 and 1. This compound is widely recognized for its remarkable dielectric, ferroelectric, and piezoelectric properties. Owing to these characteristics, BST has gained significant attention in various technological applications, such as tunable capacitors, sensors, actuators, and energy harvesting devices. In this article, we will discuss the properties of BST as a ferroelectric material and its potential applications.

Ferroelectricity in BST

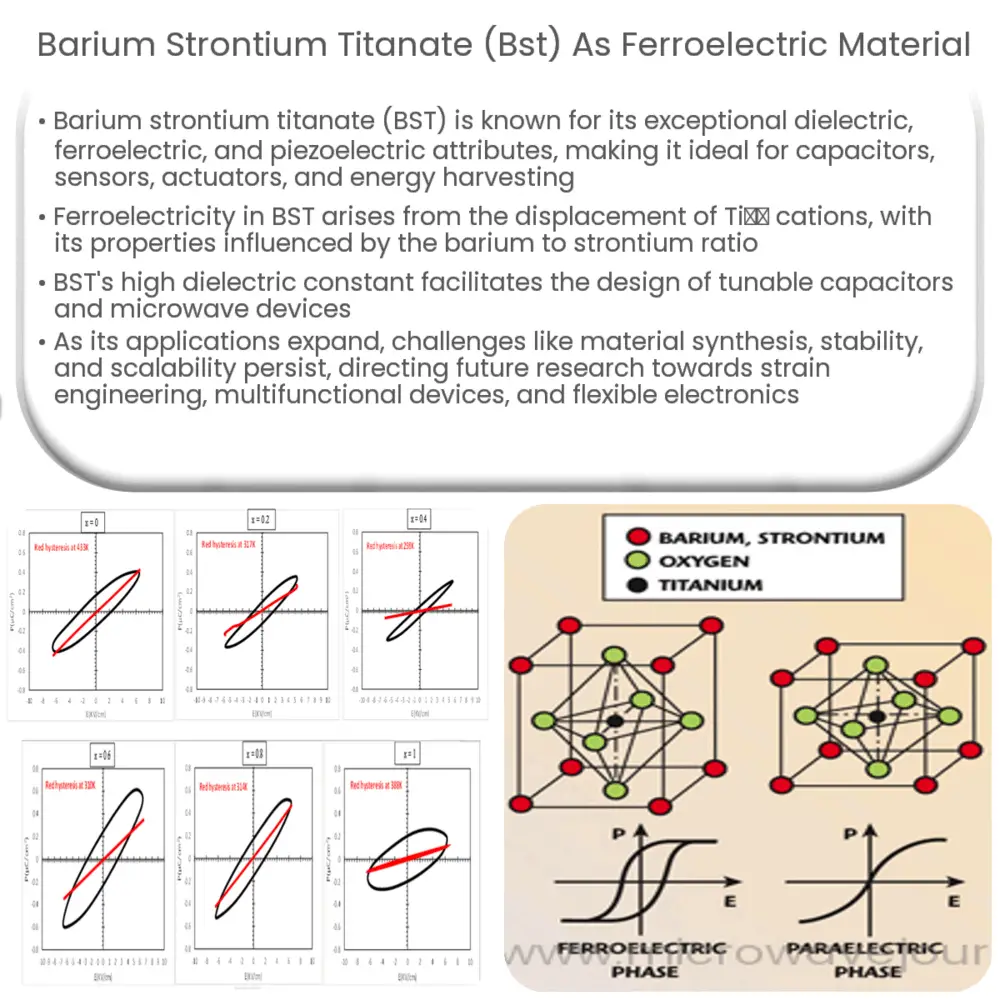

Ferroelectric materials exhibit a spontaneous polarization that can be reversed by applying an external electric field. This phenomenon is referred to as ferroelectricity, which is analogous to ferromagnetism in magnetic materials. In BST, the ferroelectric behavior arises from the displacement of Ti4+ cations relative to the center of the surrounding oxygen octahedra. This displacement results in a net electric dipole moment, giving rise to a spontaneous polarization in the material.

One of the key factors influencing the ferroelectric properties of BST is the composition, specifically the ratio of barium to strontium. The ferroelectric transition temperature, known as the Curie temperature (Tc), increases with increasing barium content. At room temperature, the ferroelectric phase is stable in BST with a barium content greater than 10%. The ferroelectric behavior of BST can also be tailored by introducing dopants, which can enhance the dielectric and ferroelectric performance of the material.

Dielectric Properties

BST exhibits a high dielectric constant, which is a measure of a material’s ability to store electrical energy. The dielectric constant of BST can be tuned by varying the composition, temperature, and applied electric field. This tunability makes BST an attractive candidate for the development of tunable capacitors and microwave devices. Moreover, BST demonstrates low dielectric loss, which is essential for minimizing energy dissipation in electronic devices.

Applications of BST

Due to its unique combination of ferroelectric, dielectric, and piezoelectric properties, BST finds a wide range of applications in various fields. Some of the prominent applications include:

- Tunable capacitors: BST-based tunable capacitors are used in frequency-agile communication systems and phase shifters, which enable the adjustment of signal frequency and phase in response to varying operating conditions.

- Sensors and actuators: The sensitivity of BST to mechanical stress and temperature changes makes it an ideal material for the development of pressure, temperature, and humidity sensors. Additionally, BST-based piezoelectric actuators have potential applications in micro-electromechanical systems (MEMS), such as inkjet printers and microfluidic devices.

- Energy harvesting: BST can be employed in energy harvesting devices, which convert mechanical vibrations or thermal energy into electrical energy. This can be particularly useful for powering remote sensors and wireless communication devices.

Thin Films and Heterostructures

In recent years, there has been a growing interest in the fabrication of BST thin films and heterostructures. Thin films offer several advantages over bulk materials, such as reduced size, weight, and power consumption, as well as improved performance due to enhanced surface-to-volume ratio. Additionally, heterostructures, which consist of alternating layers of different materials, can exhibit novel properties and functionalities not observed in their individual components.

BST thin films can be deposited using a variety of techniques, such as pulsed laser deposition, chemical vapor deposition, and sol-gel processing. The choice of deposition technique depends on factors such as film thickness, uniformity, and crystalline quality. The properties of BST thin films can be further tailored by controlling the deposition parameters and post-deposition treatments, such as annealing and etching.

Challenges and Future Directions

Despite the remarkable properties and diverse applications of BST, several challenges remain to be addressed for its widespread adoption. Some of the key challenges include:

- Material synthesis and processing: The optimization of BST synthesis methods and the control of material properties, such as stoichiometry, grain size, and crystallinity, are essential for achieving the desired performance in specific applications.

- Stability: The long-term stability of BST-based devices under various operating conditions, such as high temperature, humidity, and mechanical stress, needs to be improved for reliable operation.

- Scaling: The development of scalable fabrication techniques for BST thin films and heterostructures is necessary for the commercialization of BST-based devices.

Future research on BST should focus on addressing these challenges, as well as exploring new functionalities and applications. Some promising research directions include:

- Strain engineering: The manipulation of strain in BST thin films and heterostructures can lead to the emergence of novel properties and improved performance. For example, strain can enhance the piezoelectric response and tune the ferroelectric transition temperature.

- Multiferroic materials: The combination of BST with other ferroic materials, such as ferromagnetic and ferroelastic materials, can result in multifunctional devices with enhanced performance and novel functionalities, such as magnetoelectric coupling and voltage-controlled magnetic switching.

- Flexible electronics: The integration of BST thin films with flexible substrates can pave the way for the development of flexible electronic devices, such as wearable sensors and energy harvesters.

Conclusion

In summary, barium strontium titanate (BST) is a versatile ferroelectric material with a wide range of potential applications in electronics, communication, sensing, and energy harvesting. The tunable dielectric, ferroelectric, and piezoelectric properties of BST make it a promising candidate for the development of next-generation devices. Ongoing research on BST thin films, heterostructures, and novel functionalities is expected to further expand the potential applications and impact of this remarkable material.