Explore the role, types, and applications of Wire Mesh Grips in various industries, and learn key factors for their selection and maintenance.

Introduction to Wire Mesh Grips

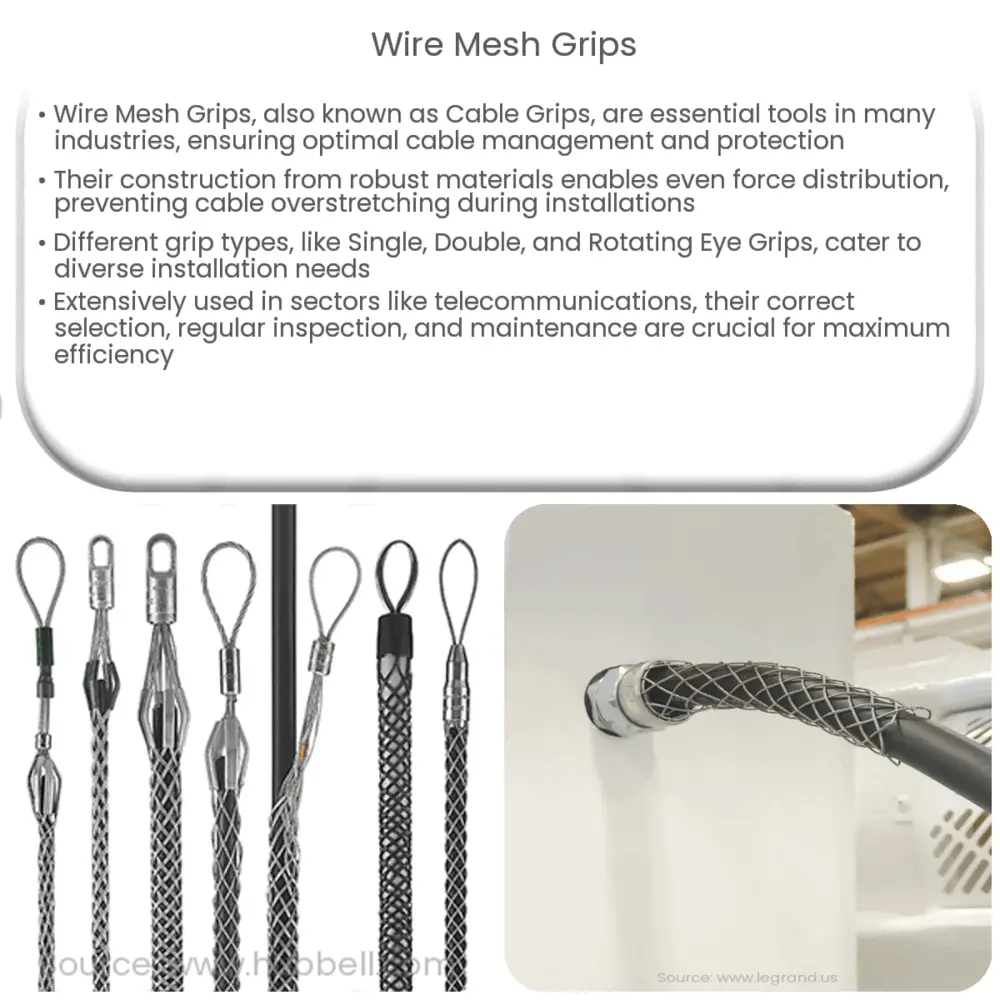

Wire Mesh Grips, also known as Cable Grips, serve as a fundamental tool in numerous industries, providing vital support in managing cables and wires. Renowned for their versatility and robustness, these devices ensure the optimal performance and protection of the wire infrastructure.

Construction and Functionality

The basic construction of a Wire Mesh Grip entails a flexible, mesh design made from robust, high-tensile strength materials such as stainless steel or galvanized steel. These grips are woven in a way that they form a sock-like structure. When a cable is inserted through this structure, it tightens around the cable as the tension increases, providing an even distribution of force across the cable’s surface.

The fundamental role of Wire Mesh Grips lies in mitigating strain on cables, particularly during the installation process. They prevent the cable from overstretching or becoming damaged by absorbing and distributing the pulling force that is exerted on the cable.

Types of Wire Mesh Grips

- Single Eye Grips: These grips are designed with a single eye or loop at the top. They are primarily used in situations where the cable has a straight path.

- Double Eye Grips: These grips are equipped with two eyes or loops. They are ideal for situations where the direction changes during the pulling process.

- Rotating Eye Grips: These grips come with a swivel or rotating eye, allowing for multi-directional pulling. They are suitable for complex installations where the pulling direction frequently changes.

Applications

Wire Mesh Grips find extensive application in a broad range of industries, including telecommunications, construction, and utility sectors. They are used for pulling electrical and fiber optic cables, overhead line construction, and submersible pump installations. The critical role they play in maintaining the integrity and longevity of cables makes them an invaluable asset to these industries.

Choosing the Right Wire Mesh Grip

Selecting the appropriate Wire Mesh Grip depends on a variety of factors such as the type and size of the cable, the direction of the pull, and the expected load or tension on the cable. It’s crucial to ensure that the grip is compatible with the specific cable dimensions and designed to withstand the estimated pulling force.

Factors to Consider when Choosing Wire Mesh Grips

The choice of Wire Mesh Grip should not be taken lightly. Several factors need to be considered to ensure optimal results.

- Cable Type: Different types of cables (like fiber optic, electrical, etc.) may require different kinds of grips.

- Cable Diameter: The diameter of the cable is another critical factor, as the grip must be able to fit snugly around it.

- Load Capacity: The grip chosen must be able to handle the maximum expected load. Overlooking this factor may lead to cable damage or failure.

- Environment: Conditions where the grip will be used also affect the choice. Factors such as exposure to water, corrosive substances, or extreme temperatures can influence the selection of grip material.

Maintenance and Inspection of Wire Mesh Grips

Regular inspection and maintenance are paramount for Wire Mesh Grips. These measures help prevent equipment failure and extend the life of the grips. Inspections should look for signs of wear and tear, such as broken strands or deformities. Furthermore, the grip should be replaced if it no longer securely fits the cable or if it has been subjected to a heavy load.

Conclusion

Wire Mesh Grips are an integral component in many industries, playing a significant role in the management and protection of cables and wires. They ensure the safe and effective installation and operation of cables, thereby promoting efficiency and reducing potential costs related to damage and maintenance. The selection of the appropriate Wire Mesh Grip requires careful consideration of various factors, and their ongoing inspection and maintenance are crucial for optimal performance. In essence, these unassuming devices are the unsung heroes maintaining the integrity of complex cable systems across various sectors.