Electrical conductivity affects electroplating efficiency, coating uniformity, energy consumption, and corrosion resistance of the plated material.

Electrical Conductivity in Electroplating and Metal Deposition

Electrical conductivity plays a crucial role in electroplating and metal deposition processes, affecting the quality, efficiency, and uniformity of the plated coatings. This article discusses the significance of electrical conductivity in these processes and how it influences their outcome.

Electroplating Process

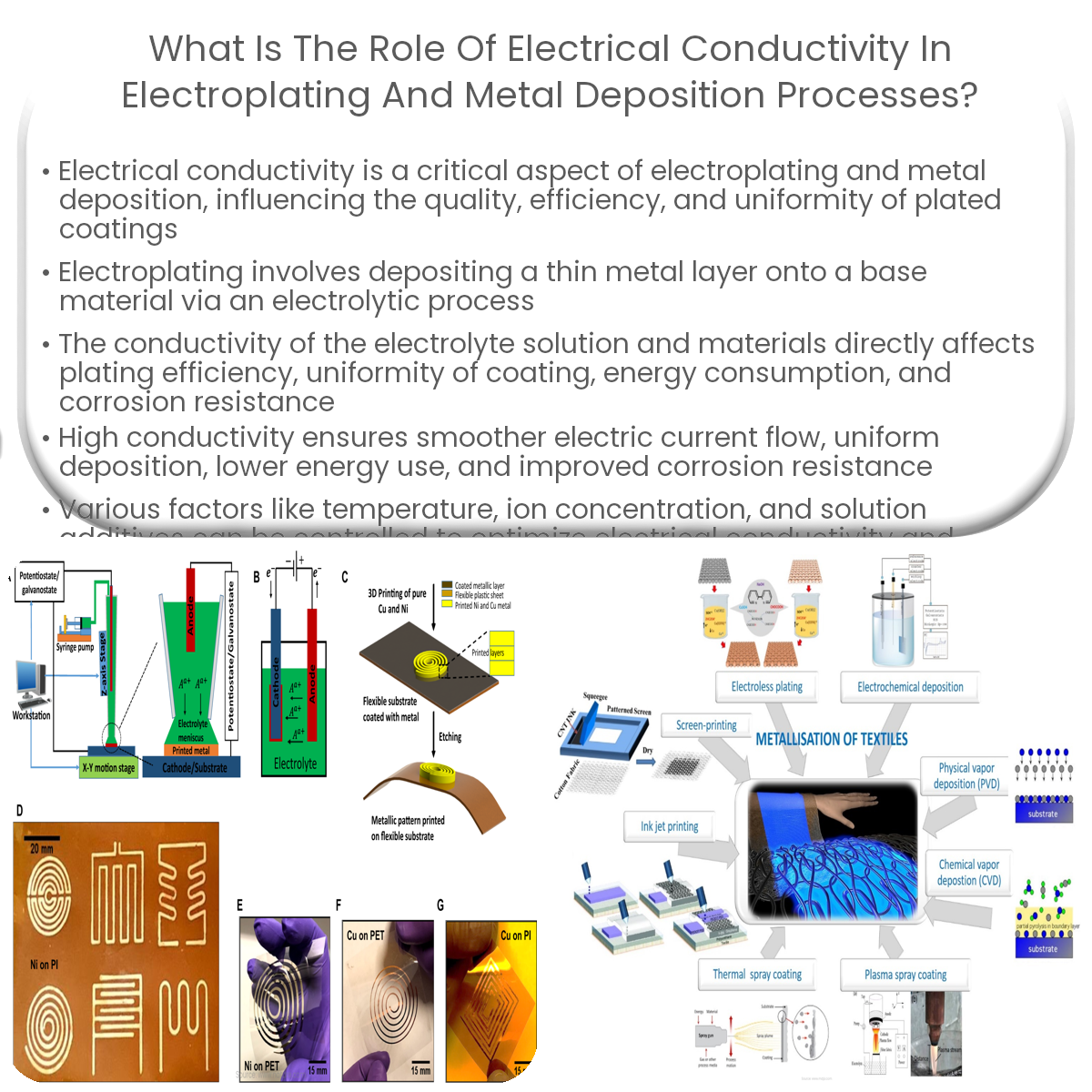

Electroplating is a technique used to deposit a thin layer of one metal onto another, typically a base material, through an electrolytic process. The base material, known as the cathode, is immersed in an electrolyte solution containing ions of the metal to be deposited. The anode, usually composed of the plating metal, is also submerged in the solution. A direct current is passed through the circuit, causing the metal ions to move from the anode to the cathode, where they are reduced and deposited as a thin layer on the surface of the base material.

Role of Electrical Conductivity

Electrical conductivity is the measure of a material’s ability to conduct electric current. In electroplating and metal deposition processes, the electrical conductivity of the electrolyte solution and the materials involved directly affects the following aspects:

- Plating Efficiency: High electrical conductivity in the electrolyte solution ensures a smoother flow of electric current, leading to better plating efficiency and faster deposition rates.

- Uniformity of Coating: A uniform electric field within the electrolyte solution, facilitated by high conductivity, results in even deposition of the metal on the base material, producing a consistent and uniform coating.

- Energy Consumption: Materials with higher electrical conductivity require less energy to deposit the metal ions, reducing the overall energy consumption of the process and making it more cost-effective.

- Corrosion Resistance: A uniform and consistent coating achieved through optimal electrical conductivity enhances the corrosion resistance of the plated material, extending its lifespan and improving its performance.

Optimizing Electrical Conductivity

Various factors can influence the electrical conductivity of the electrolyte solution and the materials involved in electroplating and metal deposition processes. These include temperature, concentration of ions, and the presence of additives in the solution. By controlling and optimizing these factors, it is possible to achieve the desired electrical conductivity and enhance the overall performance of the electroplating process.