Electrical conductivity affects corrosion by influencing electrochemical reactions, galvanic corrosion, localized corrosion, and corrosion protection methods.

Role of Electrical Conductivity in Corrosion Processes

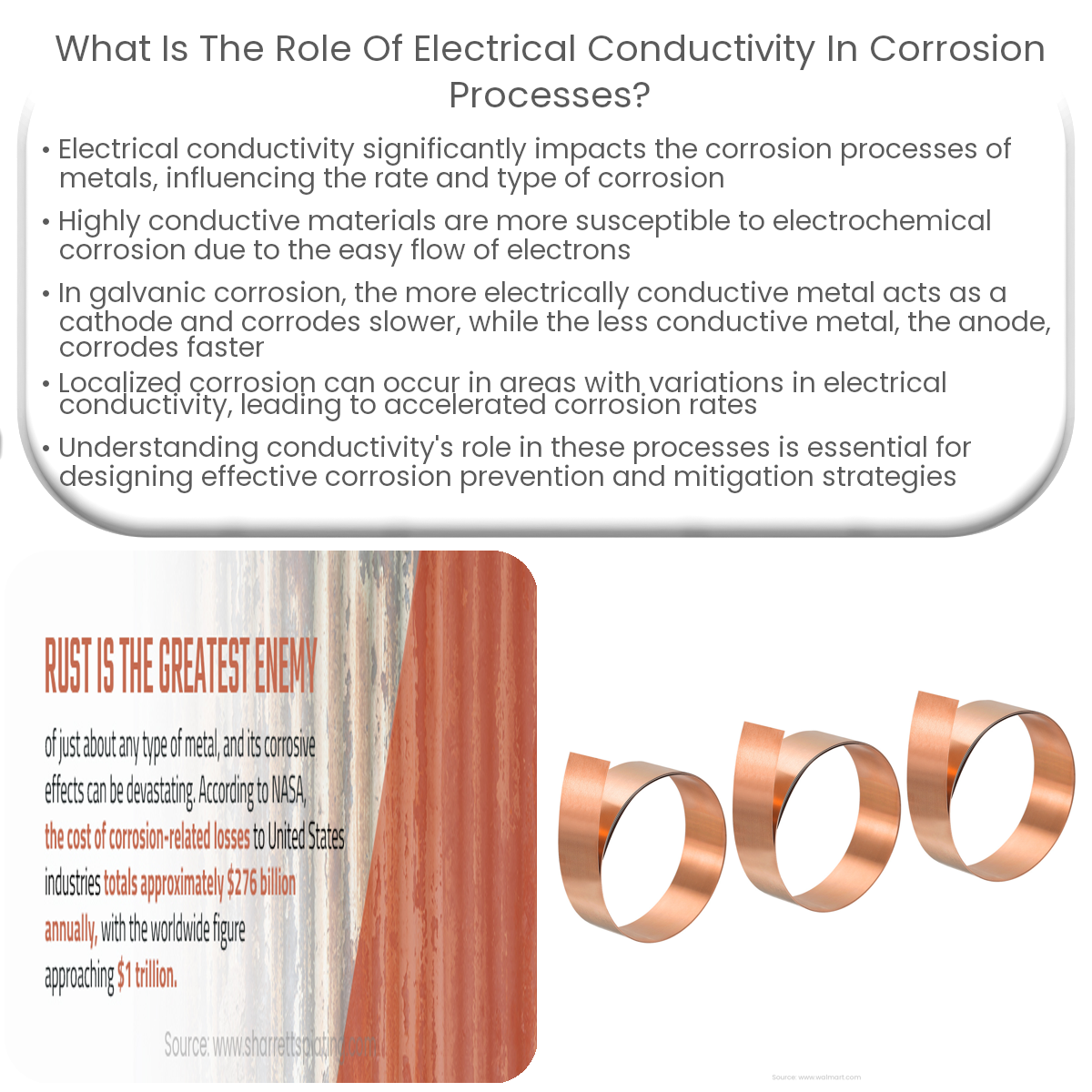

Corrosion is the natural deterioration of metals due to chemical reactions with their surrounding environment. Electrical conductivity plays a vital role in these processes, impacting the rate and type of corrosion that occurs.

Electrochemical Reactions

Corrosion is an electrochemical process, involving the flow of electrons between the metal and its environment. Electrical conductivity, the ability of a material to conduct electric current, influences the rate of these reactions. Highly conductive materials, such as copper, are more susceptible to electrochemical corrosion due to the ease of electron flow.

Galvanic Corrosion

Galvanic corrosion is a type of corrosion that occurs when two dissimilar metals are in contact in the presence of an electrolyte, such as water. The metal with higher electrical conductivity acts as a cathode, while the less conductive metal acts as an anode. The anode corrodes faster than it would alone, while the cathode corrodes more slowly or not at all. This process is particularly important in the design of structures and systems where different metals are in close proximity.

Localized Corrosion

Localized corrosion, such as pitting and crevice corrosion, can occur in areas with variations in electrical conductivity. These localized areas can create small galvanic cells, leading to accelerated corrosion rates. Controlling the electrical conductivity of a material or its environment can help mitigate the risk of localized corrosion.

Corrosion Inhibition and Protection

Understanding the role of electrical conductivity in corrosion processes is essential for developing effective corrosion protection methods. Techniques such as cathodic protection, coatings, and inhibitors rely on altering the electrical conductivity of a system to reduce the rate of corrosion. For example, cathodic protection systems introduce a more reactive metal or apply an external voltage to protect the structure, while coatings act as barriers that limit the flow of electrons and ions between the metal and its environment.

Conclusion

Electrical conductivity plays a crucial role in the corrosion processes of metals. By understanding its influence on electrochemical reactions, galvanic corrosion, and localized corrosion, engineers can develop strategies to prevent and mitigate corrosion-related damage, ultimately prolonging the life and performance of structures and systems.