Vinylidene fluoride (VDF) is a versatile ferroelectric material with potential applications in sensors, actuators, energy storage, and flexible electronics.

Vinylidene Fluoride (VDF) as Ferroelectric Material

Introduction

Vinylidene fluoride (VDF) is a widely-studied ferroelectric material that has garnered significant attention in recent years due to its potential applications in a diverse range of industries. Its unique combination of properties, such as high dielectric constant, large electrostrictive strain, and excellent thermal stability, make it a promising candidate for various applications, including sensors, actuators, and energy storage devices. In this article, we will explore the fundamentals of VDF, its ferroelectric properties, and potential applications.

Fundamentals of Vinylidene Fluoride (VDF)

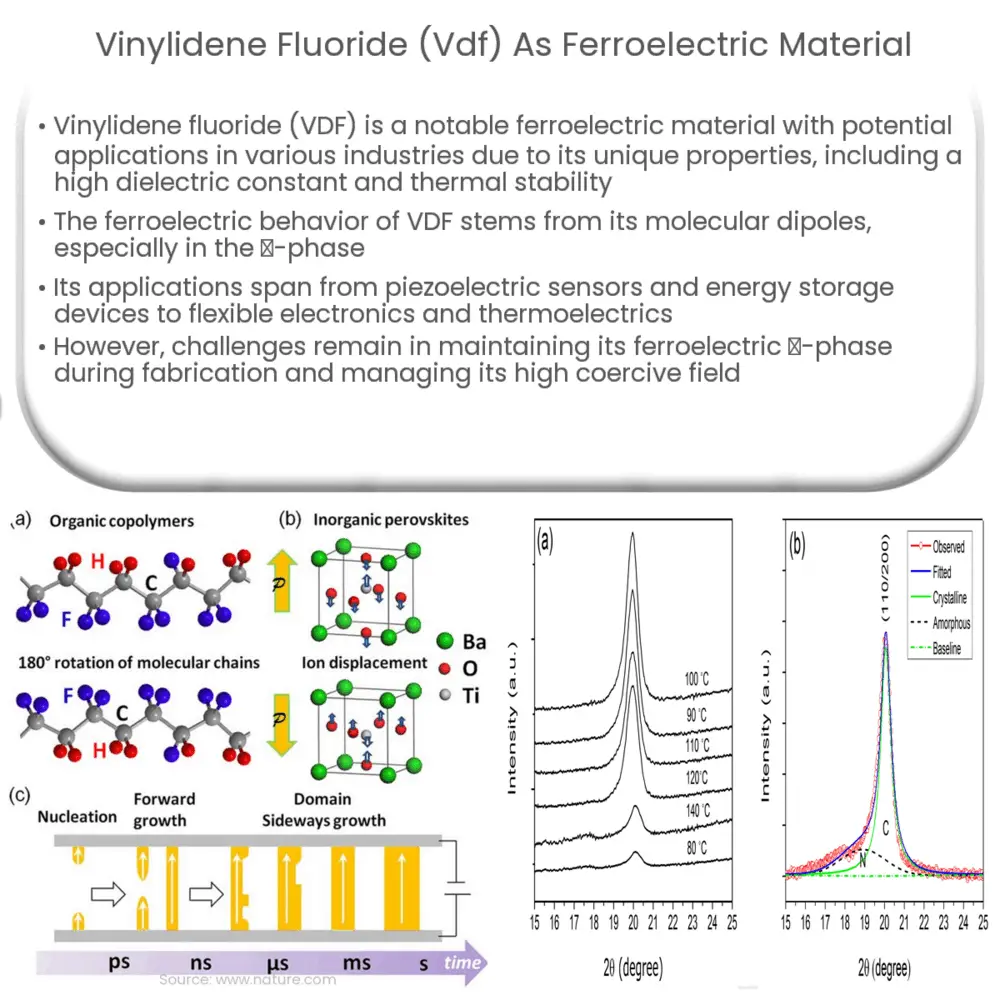

Vinylidene fluoride, or CH2CF2, is an organic compound belonging to the family of halogenated olefins. It is a colorless, odorless gas at room temperature and standard atmospheric pressure. VDF is a polymerizable molecule, and its polymer, polyvinylidene fluoride (PVDF), is a semi-crystalline thermoplastic material with a high degree of chemical resistance and excellent mechanical properties. PVDF can exist in several crystalline phases, including α, β, γ, and δ. The β-phase is of particular interest due to its ferroelectric properties.

Ferroelectric Properties of VDF

The ferroelectric behavior of VDF arises from the spontaneous polarization of its molecular dipoles. In the β-phase, the polymer chains adopt a trans-gauche conformation, resulting in a net dipole moment. The application of an external electric field can cause the dipoles to reorient, leading to a change in the polarization of the material. This polarization change is reversible, meaning that the material can be switched between its polarized and depolarized states multiple times without degradation, making VDF an attractive candidate for ferroelectric applications.

One key characteristic of ferroelectric materials is the presence of a hysteresis loop in their polarization-electric field (P-E) plots. VDF exhibits a well-defined hysteresis loop, confirming its ferroelectric nature. Other important ferroelectric properties of VDF include its high dielectric constant, which can exceed 10, and its high remanent polarization, which is the residual polarization after the removal of the external electric field. These properties make VDF a highly attractive material for various applications, as we will discuss in the next section.

Applications of VDF as a Ferroelectric Material

VDF’s unique ferroelectric properties have paved the way for its use in a wide range of applications. Its high dielectric constant makes it suitable for capacitors with high energy storage density, while its large electrostrictive strain makes it an excellent candidate for sensors and actuators. Additionally, VDF’s ability to maintain its ferroelectric properties at high temperatures makes it ideal for applications in harsh environments, such as aerospace and automotive industries. Some specific applications of VDF as a ferroelectric material include:

- Piezoelectric sensors: VDF can be used to create highly sensitive piezoelectric sensors for detecting pressure, force, or acceleration in various industries.

- Energy storage devices: VDF’s high dielectric constant and remanent polarization make it an ideal candidate for use in energy storage devices, such as supercapacitors and high-density capacitors.

- Actuators: The electrostrictive properties of VDF make it suitable for the development of micro-actuators and micro-electromechanical systems (MEMS) used in applications such as robotics and microfluidics.

- Non-volatile memory devices: VDF’s ferroelectric properties can be exploited to develop non-volatile memory devices, which can retain stored data even in the absence of power, making them suitable for low-power electronics.

- Flexible electronics: The flexibility and mechanical robustness of VDF-based materials enable their use in flexible electronic devices, such as wearable sensors and flexible displays.

- Thermoelectric materials: VDF’s ability to maintain its ferroelectric properties at high temperatures makes it a promising candidate for thermoelectric applications, such as power generation from waste heat.

Challenges and Future Prospects

Despite its numerous advantages, there are still some challenges that need to be addressed to fully exploit the potential of VDF as a ferroelectric material. One of the primary challenges is the difficulty in obtaining and maintaining the ferroelectric β-phase during the fabrication process. The presence of other phases in the material can lead to reduced ferroelectric performance. Researchers are continuously exploring new processing methods and material combinations to improve phase purity and enhance the performance of VDF-based devices.

Another challenge is the relatively high coercive field of VDF, which is the minimum electric field required to switch its polarization direction. This high coercive field can lead to increased energy consumption in some applications. Research is being conducted to reduce the coercive field while maintaining the desirable ferroelectric properties of the material.

As research on VDF progresses, its potential applications in various industries continue to expand. With ongoing developments in material science, the properties of VDF can be further optimized, and its compatibility with different fabrication processes can be improved. The future of VDF as a ferroelectric material looks promising, and its potential impact on the fields of electronics, energy, and sensing technology is immense.

Conclusion

Vinylidene fluoride (VDF) is a versatile ferroelectric material with a wide range of potential applications, including sensors, actuators, energy storage devices, and flexible electronics. Its unique combination of properties, such as high dielectric constant, large electrostrictive strain, and excellent thermal stability, make it an attractive candidate for various industries. Although there are still challenges to be overcome, ongoing research and development efforts continue to push the boundaries of VDF’s potential applications, paving the way for new technologies and innovations.