A vector impedance meter measures complex impedance, helping engineers analyze electronic components and circuits in AC conditions.

Vector Impedance Meter: An Essential Tool for Electronic Testing

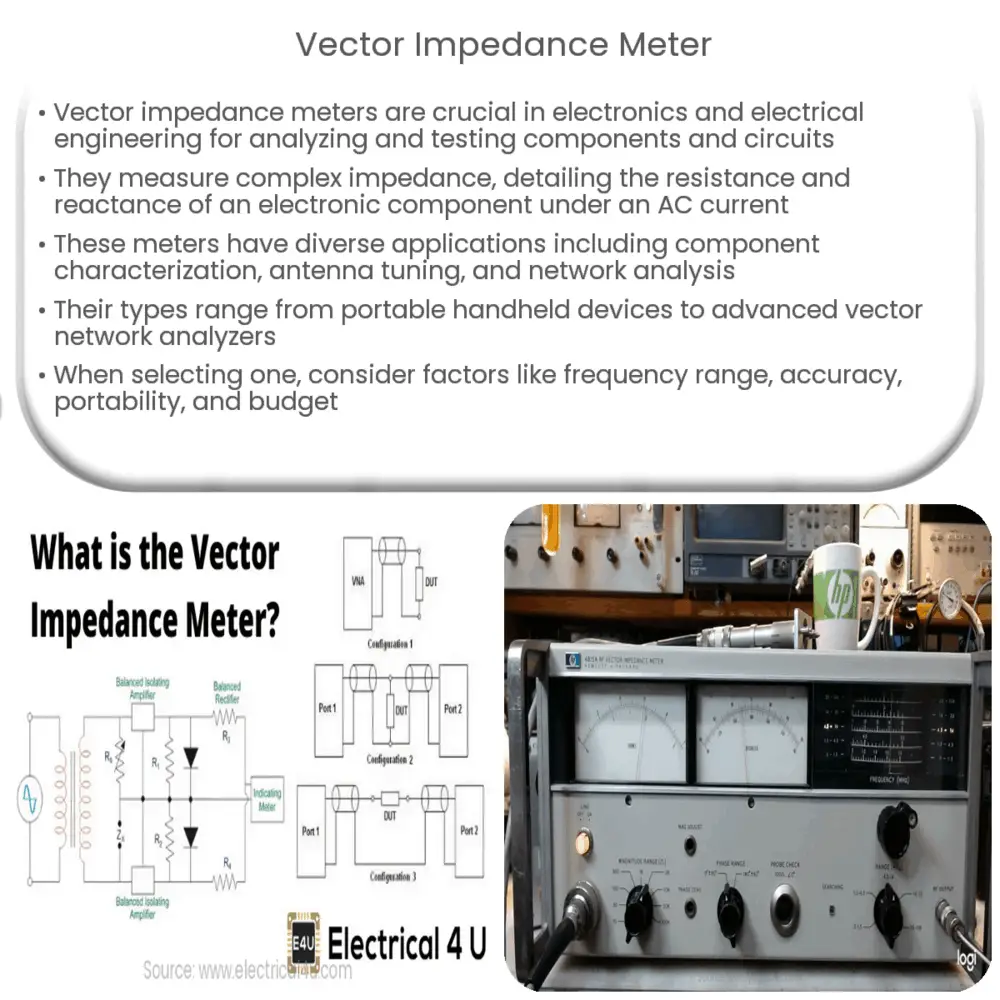

Vector impedance meters are essential tools in the field of electronics and electrical engineering, playing a crucial role in testing and analyzing components and circuits. They are used to measure complex impedance, a property that describes the resistance and reactance of an electronic component when an alternating current (AC) is applied to it. This article provides an introduction to vector impedance meters, their applications, and their importance in the electronics industry.

Understanding Impedance and Its Components

Impedance is a vital concept in electronics, as it determines how a component or circuit will behave when subjected to an AC signal. It is a complex quantity, consisting of two components: resistance (R) and reactance (X). Resistance is the opposition to the flow of direct current (DC) and is measured in ohms (Ω). Reactance, on the other hand, is the opposition to the flow of AC and is also measured in ohms. Reactance can be further subdivided into capacitive reactance (Xc) and inductive reactance (Xl).

Impedance (Z) can be represented as a complex number, with resistance as the real part and reactance as the imaginary part. Mathematically, it can be expressed as Z = R + jX, where j is the imaginary unit. This representation is crucial for understanding the behavior of electronic components in AC circuits and designing efficient systems.

Vector Impedance Meter: Function and Operation

A vector impedance meter is an instrument designed to measure the complex impedance of electronic components and circuits. It operates by applying a known AC voltage or current to the device under test (DUT) and measuring the resulting current or voltage, respectively. By comparing the phase difference and magnitude between the applied signal and the measured response, the instrument can calculate the impedance of the DUT.

Modern vector impedance meters employ sophisticated digital signal processing techniques to provide accurate and reliable impedance measurements across a wide frequency range. They can display the results in various formats, such as polar coordinates (magnitude and phase angle) or rectangular coordinates (real and imaginary parts), facilitating the interpretation and analysis of the data.

Applications of Vector Impedance Meters

Vector impedance meters are widely used in various electronic testing and development scenarios, including:

- Component characterization: Engineers use vector impedance meters to determine the impedance characteristics of electronic components, such as resistors, capacitors, and inductors, which are crucial for designing circuits and systems.

- Antenna tuning and analysis: In radio frequency (RF) applications, vector impedance meters are indispensable tools for measuring the impedance of antennas, ensuring optimal performance and efficient power transfer between the transmitter and the antenna.

- Network analysis: Vector impedance meters can also be used to analyze the performance of complex circuits and systems by measuring their impedance response over a wide frequency range. This information is essential for identifying and resolving issues related to signal integrity, crosstalk, and overall system performance.

As the electronics industry continues to evolve, the demand for precise and reliable impedance measurement tools grows, and vector impedance meters remain a cornerstone technology for achieving these goals.

Types of Vector Impedance Meters

There are several types of vector impedance meters available in the market, each with its unique set of features and capabilities. Some of the most common types include:

- Handheld vector impedance meters: These portable devices are designed for field use, offering mobility and ease of operation. They are ideal for on-site measurements and troubleshooting of electronic components and systems, such as antennas, filters, and transmission lines.

- Benchtop vector impedance meters: These devices are designed for laboratory and research settings, providing higher accuracy and a broader range of features than handheld models. They are well-suited for in-depth analysis, characterization, and testing of electronic components and circuits.

- Vector network analyzers (VNAs): These highly sophisticated instruments are capable of measuring not only impedance but also other complex parameters, such as S-parameters, in multi-port networks. VNAs are widely used in the design and analysis of high-frequency circuits and systems, such as those used in telecommunications, radar, and microwave applications.

Selecting the Right Vector Impedance Meter

Choosing the appropriate vector impedance meter for your needs depends on several factors, including:

- Frequency range: Ensure that the meter covers the frequency range of interest for your application. For example, a radio frequency engineer working with antennas might require a meter with a higher frequency range than an engineer working on audio circuits.

- Accuracy and resolution: Consider the level of accuracy and resolution required for your measurements. High-precision instruments are essential for characterizing critical components or systems, but they often come with a higher price tag.

- Portability: If you need to perform measurements in the field or at various locations, a handheld vector impedance meter might be the best choice.

- Additional features: Some vector impedance meters come with extra features, such as built-in data logging, programmable test sequences, and compatibility with external software for data analysis and reporting. Evaluate whether these features are necessary for your specific application.

- Budget: Finally, consider the cost of the instrument in relation to your budget and the value it provides for your specific needs.

Conclusion

Vector impedance meters are indispensable tools for the analysis and testing of electronic components and systems. They provide valuable insights into the behavior of circuits and components under AC conditions, enabling engineers to design more efficient and reliable systems. With various types of meters available, it is essential to carefully consider the specific requirements of your application and choose the right instrument to ensure accurate and reliable measurements.