A time-delay fuse is a safety component that protects electrical circuits from overloads, allowing temporary surges before interrupting the circuit.

Understanding Time-Delay Fuses: Function, Application, and Design

Introduction

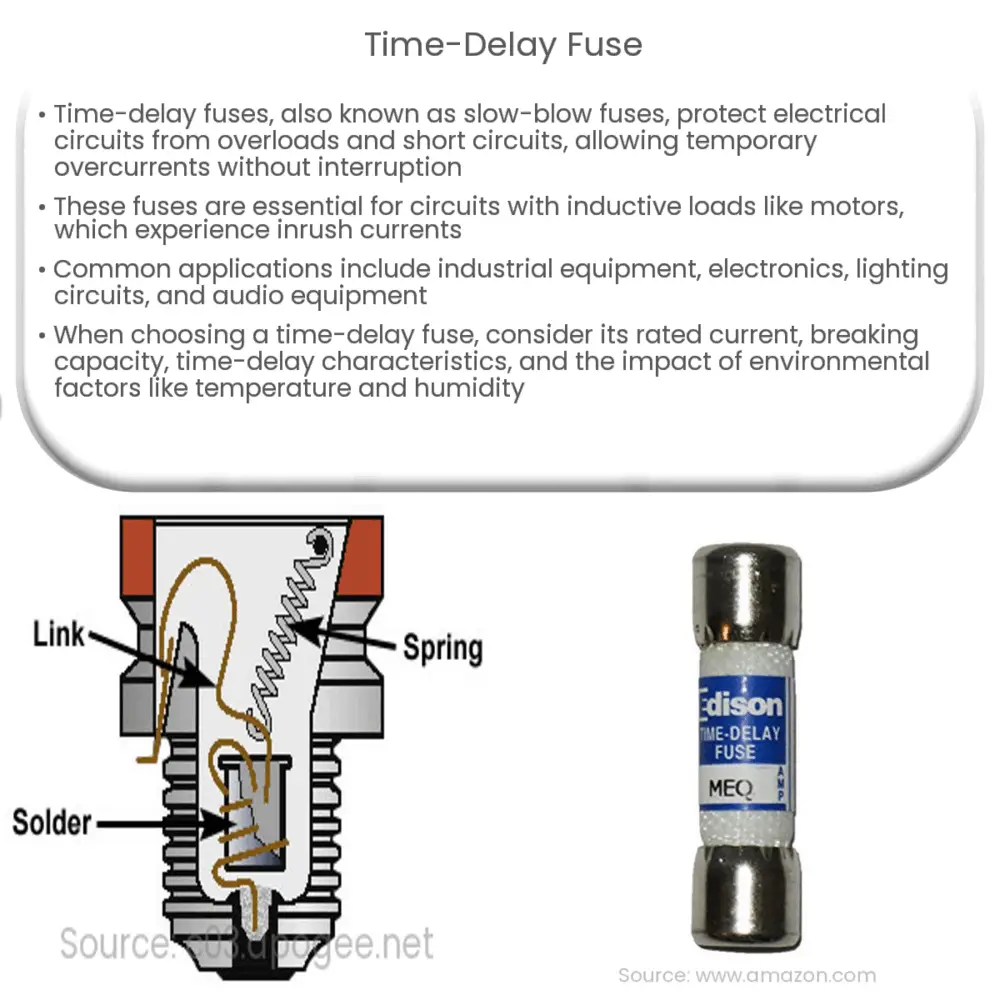

A time-delay fuse, also known as a slow-blow fuse, is an essential safety component designed to protect electrical circuits from overloads and short circuits. Unlike a standard fuse that operates instantly when a fault occurs, a time-delay fuse provides a specific time window before it interrupts the circuit. This feature allows for temporary, harmless overcurrent conditions that may arise in various applications. In this article, we will delve into the functionality, application, and design of time-delay fuses.

Functionality of Time-Delay Fuses

A time-delay fuse consists of a fusible link, which is typically made of a metal alloy designed to melt when exposed to excessive current for a predetermined amount of time. The fuse’s time-delay characteristic depends on the physical properties and dimensions of the fusible link. This design ensures that the fuse only operates when a sustained overcurrent condition is present, rather than reacting to short-duration surges that can occur during normal operation.

Time-delay fuses are particularly useful in circuits with inductive loads, such as motors, transformers, and solenoids. These devices often experience inrush currents, which are temporary surges of current that can reach several times the rated operating current. Inrush currents are not necessarily harmful to the equipment, but they can cause standard fuses to blow prematurely. By employing a time-delay fuse, these temporary overcurrent events can be tolerated without interrupting the circuit.

Applications of Time-Delay Fuses

Time-delay fuses find use in a wide range of applications that require protection against sustained overcurrent conditions. Some common applications include:

- Industrial Equipment: Motors, pumps, and other heavy-duty machinery often experience inrush currents when starting up. Time-delay fuses are used to protect these devices from damage caused by sustained overcurrents without interrupting their normal operation.

- Electronics: Power supplies, inverters, and other electronic devices may require time-delay fuses to safeguard sensitive components from damage caused by sustained overcurrents or short circuits.

- Lighting Circuits: Some types of lighting systems, such as HID (High-Intensity Discharge) lamps, can generate inrush currents during startup. Time-delay fuses help prevent nuisance tripping caused by these temporary surges.

- Audio Equipment: Amplifiers and speaker systems can draw significant amounts of current during operation, particularly when experiencing audio peaks. Time-delay fuses offer protection from prolonged overcurrents without interrupting the audio signal during normal operation.

Design Considerations for Time-Delay Fuses

When selecting a time-delay fuse for a specific application, several factors must be considered. These include the fuse’s rated current, breaking capacity, and the desired time-delay characteristics. Additionally, environmental factors, such as ambient temperature and humidity, can impact the fuse’s performance and should be accounted for in the selection process.

Choosing the Right Rated Current

The rated current of a time-delay fuse is the maximum continuous current it can carry without melting the fusible link. To select the appropriate rated current, it is crucial to consider the normal operating current of the device or circuit being protected. As a general rule, the fuse’s rated current should be 125% to 150% of the device’s nominal current, which helps account for any potential current fluctuations during regular operation.

Breaking Capacity

Breaking capacity, also known as interrupting rating, is the maximum fault current a fuse can safely interrupt without causing damage or posing a safety hazard. When selecting a time-delay fuse, ensure that its breaking capacity is equal to or greater than the maximum fault current that could potentially occur in the circuit. This value is usually specified by the circuit designer or can be calculated based on the circuit’s parameters.

Time-Delay Characteristics

Time-delay characteristics refer to the fuse’s response time when subjected to an overcurrent condition. These characteristics depend on factors such as the fusible link’s material, dimensions, and design. Time-delay fuses are available in various time-delay classes, which define their response time under specific overcurrent conditions. When selecting a fuse, consider the application’s requirements to determine the appropriate time-delay class. For instance, circuits with inductive loads may require a longer time delay to tolerate inrush currents, while resistive loads may require a shorter time delay for adequate protection.

Environmental Factors

Environmental factors, such as ambient temperature and humidity, can influence the performance of a time-delay fuse. High temperatures can cause the fusible link to melt at lower currents, while low temperatures may make the fuse more resistant to overcurrent conditions. It is crucial to select a fuse that is rated for the specific operating conditions of the application, taking into account any temperature and humidity fluctuations that may occur during regular operation.

Conclusion

Time-delay fuses are essential components in various applications, offering protection against sustained overcurrents without reacting to short-duration surges. When selecting a time-delay fuse, consider factors such as rated current, breaking capacity, time-delay characteristics, and environmental conditions to ensure optimal performance and protection for your specific application. By understanding the functionality, application, and design considerations of time-delay fuses, you can make informed decisions when selecting the appropriate fuse for your needs, ensuring the safety and reliability of your equipment and circuits.