Explore the importance, composition, types, and applications of thermal pads in electronics for efficient heat management.

Introduction to Thermal Pads

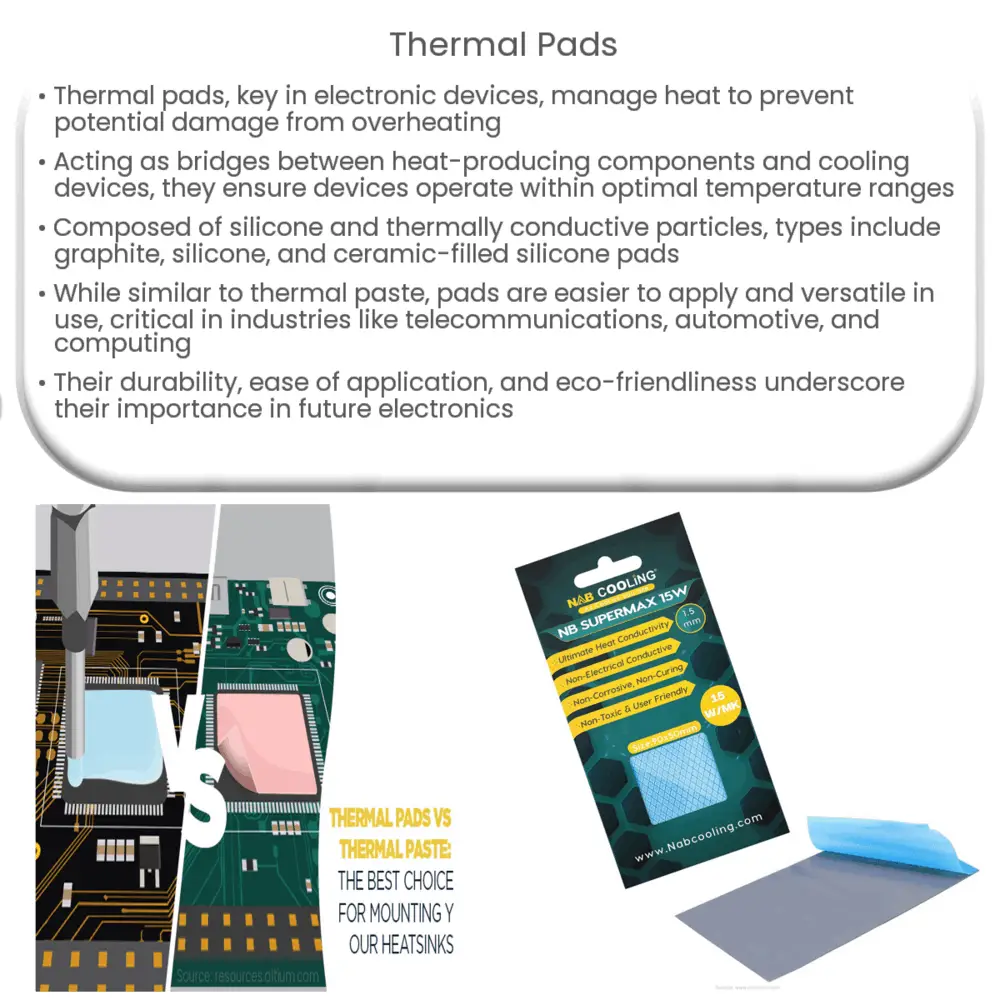

Thermal pads, also referred to as thermally conductive pads, are a crucial component in the realm of electronic devices. They serve a significant role in managing the heat generated during the operation of these devices, effectively safeguarding them from potential damage induced by overheating.

Role of Thermal Pads

Heat is a by-product of electricity, particularly in components such as processors, which can generate substantial heat due to their high-speed operations. Excessive heat can lead to diminished performance, accelerated wear and tear, and, in severe cases, can cause permanent damage to the components. This is where thermal pads come into play.

-

Thermal pads act as a bridge, filling the gap between heat-producing components and heat sinks or other cooling devices, enhancing the device’s overall thermal management.

-

They are specifically designed to conduct heat away from sensitive components, ensuring that the device operates within its optimal temperature range.

Composition and Types of Thermal Pads

Thermal pads are generally composed of a silicone-based material filled with thermally conductive particles. This combination provides high thermal conductivity while remaining non-electrically conductive, an essential feature to prevent short-circuits.

-

Graphite Thermal Pads: They offer exceptional thermal conductivity. These pads are ideal for high-performance applications.

-

Silicone Thermal Pads: These are popular due to their flexibility and wide temperature range. Silicone thermal pads are commonly used in consumer electronic devices.

-

Ceramic Filled Silicone Pads: Offering better performance than regular silicone pads, these are composed of ceramic particles within the silicone matrix, improving thermal conductivity.

Thermal Pads vs. Thermal Paste

While both thermal pads and thermal paste serve the same purpose – to enhance heat transfer between components and heat sinks – they differ in their application and performance.

-

Thermal pads are easier to apply and less messy compared to thermal paste. They also maintain their physical properties over a broad temperature range, making them ideal for long-term applications.

-

On the other hand, thermal paste offers superior thermal conductivity, making it a more effective solution for high-performance applications where minor temperature differences can impact performance.

Choosing Between Thermal Pads and Paste

Choosing between thermal pads and thermal paste ultimately depends on the specific needs of your application. If convenience and less mess are your primary concerns, thermal pads are the better choice. They come in a range of thicknesses and can be cut to fit any shape or size. However, if high performance and superior heat transfer are required, thermal paste, despite its messier application, is the superior choice.

Application of Thermal Pads

Thermal pads are extensively used across various industries, including telecommunications, automotive, and computing. They are crucial for cooling LED lights, power supplies, memory modules, graphic processors, and many other heat-generating components in electronic devices.

-

Telecommunications: With the advent of 5G and increased data processing demands, thermal management has become crucial in telecommunications equipment. Thermal pads are used in these devices to dissipate heat efficiently.

-

Automotive: In the automotive industry, thermal pads are used in electric vehicles’ batteries and power control modules to manage heat.

-

Computing: In the realm of personal computers and servers, thermal pads are used to cool CPUs, GPUs, and other components that generate significant amounts of heat.

Advantages of Using Thermal Pads

Thermal pads provide numerous benefits in addition to their primary function of transferring heat. They offer:

-

Easy Application: Thermal pads are easy to apply and can be custom cut to fit any size or shape of component.

-

Durability: These pads have a long lifespan and can withstand repeated heating and cooling cycles without degradation.

-

Eco-friendly: Many thermal pads are eco-friendly, being both recyclable and non-toxic.

Conclusion

In conclusion, thermal pads play an indispensable role in the thermal management of electronic devices. Their ability to effectively dissipate heat, coupled with their ease of application and durability, make them a preferred choice in many industries. As electronics continue to evolve and shrink, the importance of effective thermal management will only increase, making the humble thermal pad a significant player in the future of electronics.