Thermal conductivity gas sensors detect and measure gas concentrations using heat transfer properties, with applications in environmental monitoring, industrial control, and healthcare.

Thermal Conductivity Gas Sensor: An Overview

Introduction

Thermal conductivity gas sensors are versatile devices used to detect and measure the concentration of various gases in an environment. These sensors leverage the unique thermal conductivity properties of gases to provide accurate and reliable measurements. This article will discuss the basic principles, types, and applications of thermal conductivity gas sensors, as well as their advantages and disadvantages.

Principle of Operation

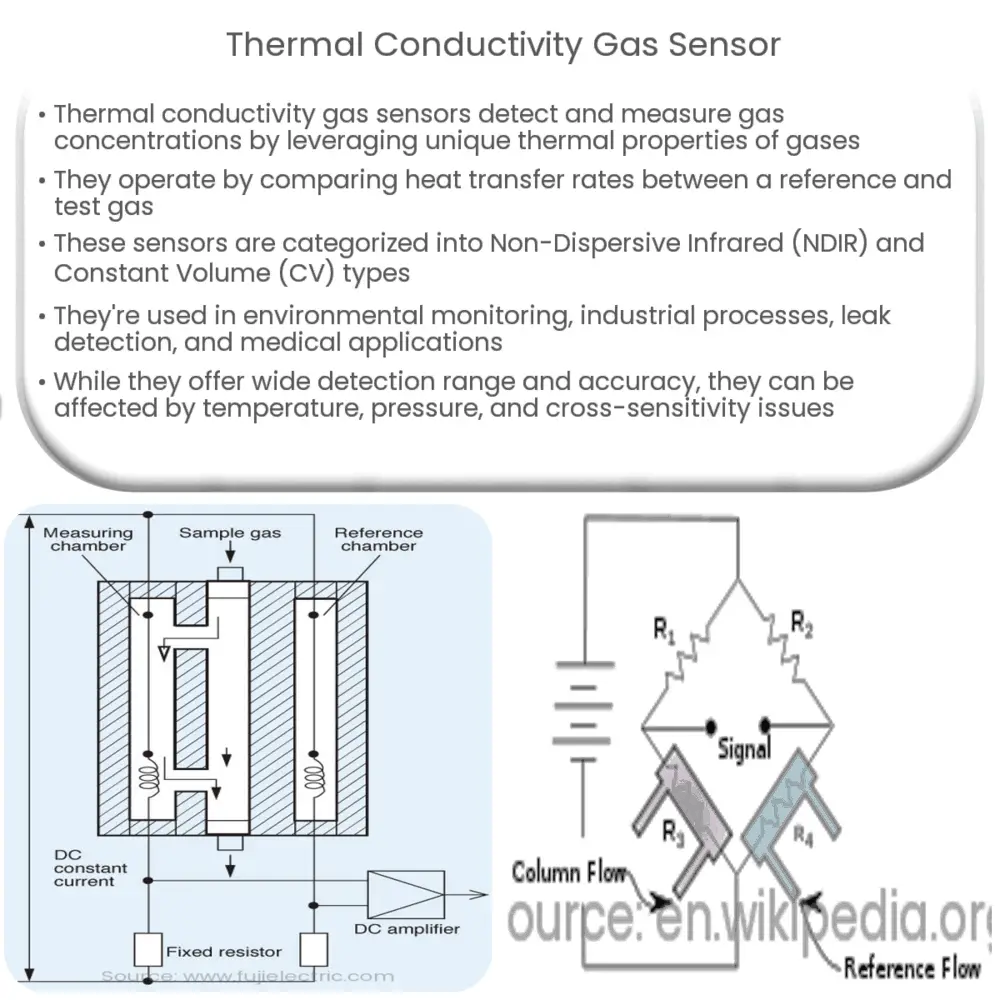

Thermal conductivity is the ability of a material to conduct heat. Gases exhibit different thermal conductivity properties, which can be used to identify and quantify their presence. The thermal conductivity gas sensor operates by measuring the heat transfer rate between a heated element and the surrounding gas. The rate of heat transfer is directly proportional to the thermal conductivity of the gas, and it varies as the gas composition changes.

The sensor typically consists of two thermopiles, one placed in a reference gas and the other exposed to the test gas. Each thermopile contains a heated element and a temperature sensor. The heat transfer rate from the heated element to the surrounding gas is determined by the temperature difference between the two thermopiles. When the test gas has a different thermal conductivity than the reference gas, the temperature difference between the thermopiles changes, providing a measurable signal that can be used to determine the gas concentration.

Types of Thermal Conductivity Gas Sensors

Thermal conductivity gas sensors can be broadly classified into two categories:

- Non-Dispersive Infrared (NDIR) Sensors: These sensors use infrared radiation to measure the thermal conductivity of gases. An infrared source emits radiation, which passes through the test gas and is absorbed by the gas molecules. The absorbed radiation heats the gas, changing its thermal conductivity. An infrared detector measures the amount of radiation that passes through the test gas, and the change in thermal conductivity is calculated based on the difference in the detector’s output signal.

- Constant Volume (CV) Sensors: In these sensors, a fixed volume of test gas is enclosed in a chamber with a heated element. The heat transfer rate between the heated element and the gas is determined by monitoring the temperature change in the gas as a function of time. The sensor provides a measurement of the gas concentration by comparing the heat transfer rate in the test gas to that of a known reference gas.

Applications of Thermal Conductivity Gas Sensors

Thermal conductivity gas sensors find applications in various industries due to their versatility and ability to detect a wide range of gases. Some of the most common applications include:

- Environmental Monitoring: These sensors are used to detect and monitor air quality, greenhouse gases, and pollutant levels in both indoor and outdoor environments.

- Industrial Process Control: Thermal conductivity gas sensors are used to monitor and control processes in industries such as chemical, petrochemical, and power generation, where gas composition plays a critical role in process efficiency and product quality.

- Leak Detection: The sensors are employed to detect leaks in gas pipelines, storage tanks, and other facilities, ensuring safety and preventing potential accidents.

- Medical Applications: In healthcare settings, these sensors are used to monitor respiratory gases and anesthesia levels, helping to maintain patient safety during surgical procedures and critical care.

Advantages and Disadvantages of Thermal Conductivity Gas Sensors

Thermal conductivity gas sensors offer several advantages, including:

- Wide Detection Range: These sensors can detect a broad range of gases, making them suitable for various applications.

- High Sensitivity and Accuracy: Thermal conductivity gas sensors provide accurate and reliable measurements, even at low gas concentrations.

- Long Life and Low Maintenance: These sensors have a long operational life and require minimal maintenance, making them cost-effective in the long run.

However, there are also some disadvantages to consider:

- Temperature and Pressure Dependency: The performance of thermal conductivity gas sensors can be affected by changes in temperature and pressure, which may require additional compensation mechanisms.

- Cross-Sensitivity: Some thermal conductivity gas sensors may exhibit cross-sensitivity to other gases, leading to false readings. This issue can be mitigated through careful sensor design and selection.

Conclusion

Thermal conductivity gas sensors offer a versatile and reliable solution for detecting and measuring various gases across multiple industries. Their wide detection range, high sensitivity, and low maintenance make them an attractive choice for many applications. However, it is essential to consider the limitations of these sensors, such as temperature and pressure dependency and cross-sensitivity, when selecting the most suitable sensor for a specific application.