Explore the essentials of Surface Potential Meters, their types, applications in diverse sectors, advantages, and considerations for selection.

Understanding Surface Potential Meters

A Surface Potential Meter is a specialized instrument used to measure the electrical potential, or voltage, present on the surface of an object. These tools are commonly used in various sectors, including electronics, manufacturing, and material science. Their primary function is to detect and quantify static electricity present on surfaces, which can have significant implications for various industrial processes and scientific research.

Working Principle of Surface Potential Meters

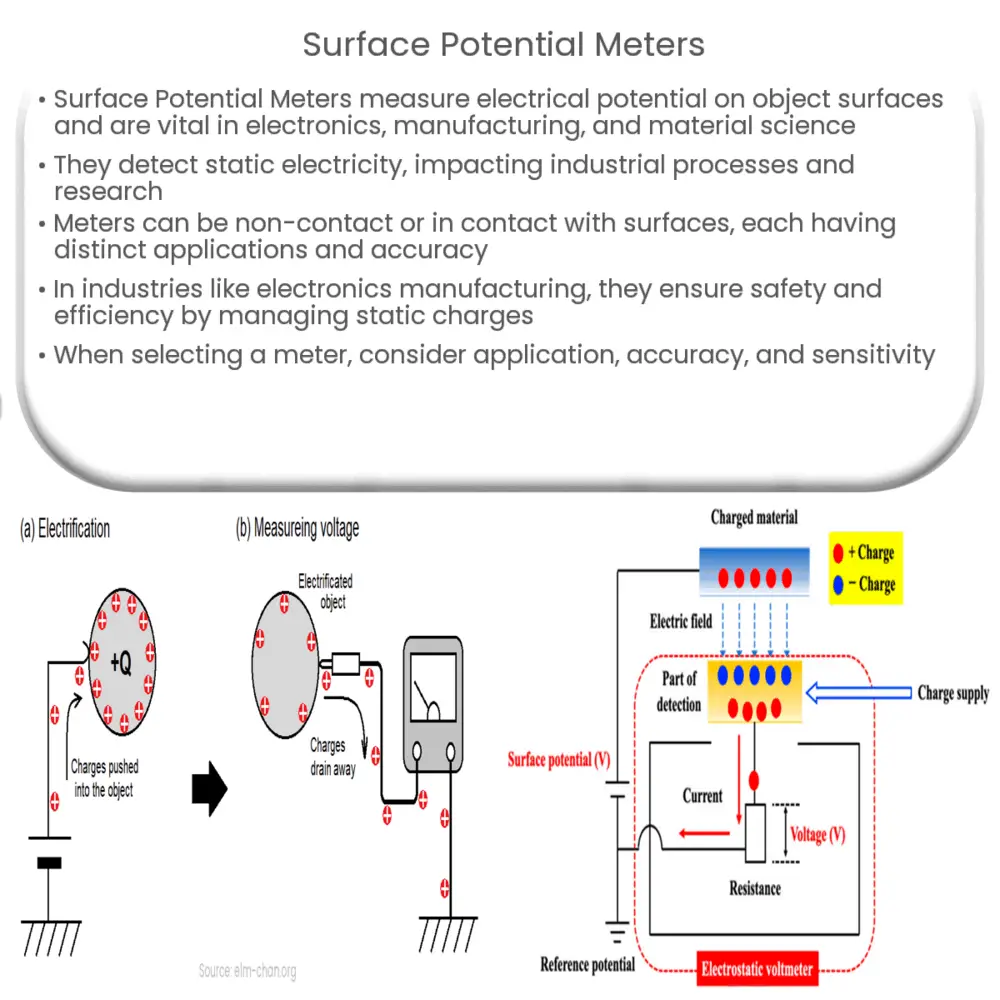

The operation of a Surface Potential Meter involves generating a balanced electrical field in its probe by adjusting its internal voltage to match the surface potential of the object being measured. As the electrical field is balanced, the voltage difference between the probe and the surface becomes zero, allowing the meter to determine the surface’s electrical potential.

Types of Surface Potential Meters

- Non-contact Surface Potential Meters: These meters are designed to measure the potential without coming into direct contact with the surface. This feature ensures there is no physical impact or charge transfer that could alter the measurements.

- Contact Surface Potential Meters: These devices are in direct contact with the surface, providing a more precise measurement. However, they might influence the surface charge during measurement, which is a significant consideration when selecting a meter type.

Applications of Surface Potential Meters

- Electronics Manufacturing: In this industry, it’s crucial to manage static electricity that can damage sensitive electronic components. Surface potential meters help identify and control static charges, thereby ensuring the safe and efficient production of electronic devices.

- Materials Science: These meters can help researchers understand the properties of different materials by measuring their surface charge. This understanding can aid in developing new materials with desired characteristics.

- Healthcare: In the biomedical field, understanding the surface charge of various materials can have significant implications for developing medical devices and pharmaceuticals. For instance, the behavior of proteins and other biomolecules can be significantly influenced by surface potential.

This encapsulates a brief overview of Surface Potential Meters, their working principles, types, and applications in various sectors. The following section will delve deeper into their uses, advantages, and what to consider when choosing a Surface Potential Meter.

Use and Advantages of Surface Potential Meters

Surface Potential Meters offer a non-destructive way of assessing the electrical charge on various surfaces. This unique feature allows repeated measurements on the same object without altering its properties, contributing to the reliability of the data collected.

The non-contact type of surface potential meter provides the added advantage of assessing the surface charge without physical interaction, making it suitable for delicate surfaces that can be easily disturbed or damaged.

Furthermore, these devices come with adjustable sensitivity levels. This allows for flexibility in measurements, ranging from high sensitivity needed for delicate electronics to lower sensitivity for broader industrial applications.

Choosing a Surface Potential Meter

When selecting a Surface Potential Meter, consider the following key factors:

- Application: The specific use case determines the type of meter required. Non-contact meters are ideal for fragile surfaces, while contact meters are more accurate and suitable for robust surfaces.

- Accuracy: The precision of measurements is critical. Higher accuracy meters will provide more reliable data but may come at a higher cost.

- Sensitivity: Depending on the range of surface potential you wish to measure, the meter’s sensitivity level should be considered.

Conclusion

In conclusion, Surface Potential Meters are indispensable tools in several industries, including electronics manufacturing, materials science, and healthcare. They provide a non-destructive means of assessing surface charges, ensuring the safety and efficiency of various manufacturing processes, and facilitating scientific research. When choosing a Surface Potential Meter, users should carefully consider their specific application, desired accuracy, and required sensitivity level to select a device that best meets their needs. Despite their intricacies, the utilization of these meters ultimately contributes to the advancement of various technological and scientific fields.