Strain gauge pressure sensors measure pressure by converting mechanical deformation into an electrical signal, offering high accuracy and versatility.

Strain Gauge Pressure Sensor: A Comprehensive Overview

A strain gauge pressure sensor is a device that measures pressure by converting the mechanical deformation experienced by a material into an electrical signal. This type of sensor is widely used across various industries and applications, including automotive, aerospace, medical, and industrial automation. In this article, we delve into the workings of strain gauge pressure sensors, their benefits, and their limitations.

Understanding the Strain Gauge Pressure Sensor

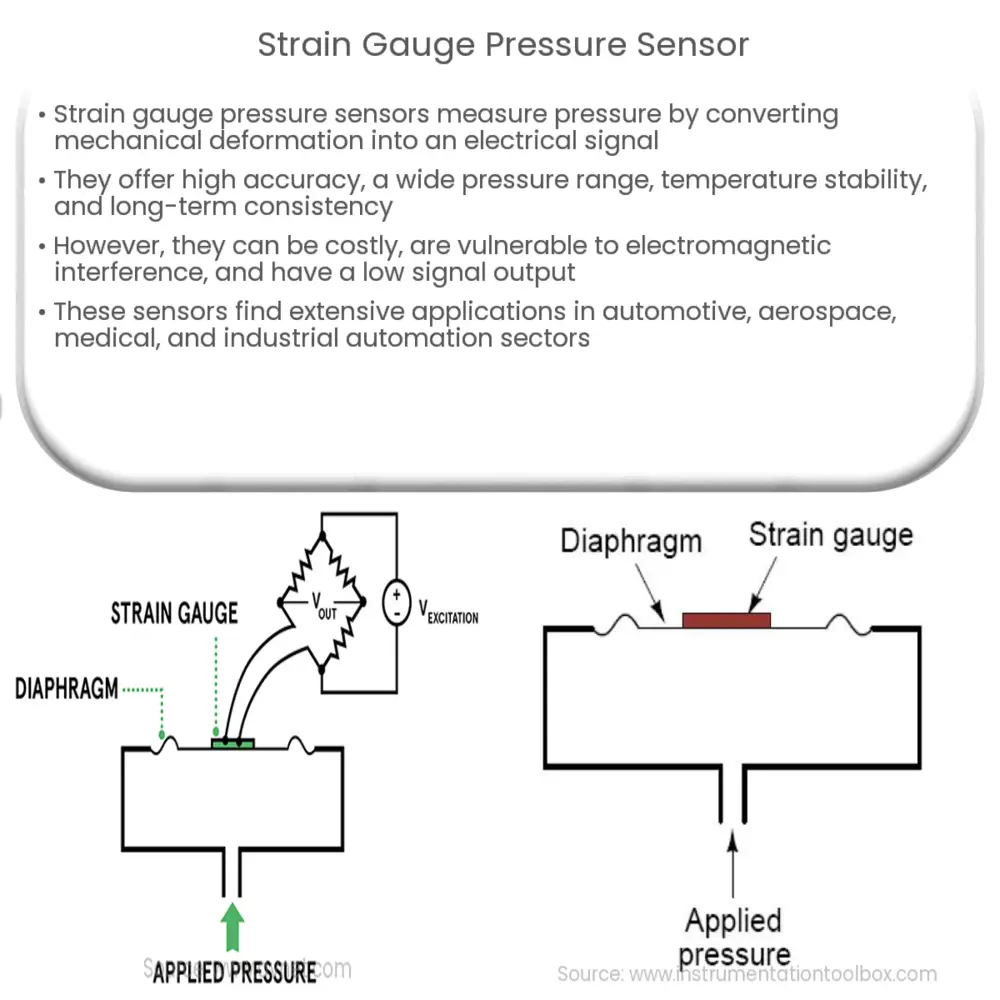

At the core of a strain gauge pressure sensor is a strain gauge, a thin, flexible material that changes its electrical resistance when it undergoes mechanical deformation. The strain gauge is typically made from a metal, such as constantan or nichrome, or a semiconductor material, like polysilicon or amorphous metal. It is bonded to a diaphragm or another structure that deforms when subjected to pressure.

As the diaphragm experiences pressure, it deforms and causes the strain gauge to change its shape as well. This change in shape leads to a change in electrical resistance, which can be measured using a Wheatstone bridge circuit. The output voltage from the Wheatstone bridge is proportional to the amount of strain experienced by the gauge, and thus to the pressure applied to the diaphragm.

Benefits of Strain Gauge Pressure Sensors

Strain gauge pressure sensors offer several advantages that make them popular choices for various applications:

- High accuracy: These sensors can achieve high levels of accuracy, typically within 0.1% to 0.5% of the full-scale pressure range. This allows for precise pressure measurements in critical applications.

- Wide pressure range: Strain gauge pressure sensors can measure pressures ranging from very low to extremely high levels, making them suitable for diverse applications.

- Good temperature stability: With proper compensation techniques, these sensors can maintain accuracy over a wide temperature range, allowing for their use in environments with significant temperature fluctuations.

- Long-term stability: Strain gauge pressure sensors exhibit excellent long-term stability, ensuring consistent performance over time.

Limitations of Strain Gauge Pressure Sensors

Despite their numerous advantages, strain gauge pressure sensors also have some limitations:

- Cost: The complexity of the sensor design and the need for precise manufacturing techniques can lead to higher costs compared to other pressure sensor types.

- Vulnerability to electromagnetic interference (EMI): The electrical signal generated by the strain gauge can be susceptible to interference from external electromagnetic sources. This can be mitigated through proper shielding and grounding techniques.

- Low signal output: The output signal from a strain gauge pressure sensor is typically in the millivolt range, requiring additional signal conditioning and amplification to be usable.

Applications of Strain Gauge Pressure Sensors

Thanks to their versatility and high accuracy, strain gauge pressure sensors are utilized in a wide range of industries and applications:

- Automotive: Strain gauge pressure sensors are used in various automotive systems, such as tire pressure monitoring, brake fluid pressure measurement, and engine oil pressure monitoring.

- Aerospace: These sensors play a crucial role in monitoring cabin pressure, fuel tank pressure, and hydraulic system pressure in aircraft and spacecraft.

- Medical: In the medical field, strain gauge pressure sensors are employed in devices like blood pressure monitors, respiratory equipment, and infusion pumps to ensure accurate and reliable pressure measurements.

- Industrial automation: Strain gauge pressure sensors are commonly used for process control, monitoring pressure in pipelines, and ensuring the safe operation of equipment in manufacturing facilities.

Selecting the Right Strain Gauge Pressure Sensor

When choosing a strain gauge pressure sensor for a specific application, several factors must be considered:

- Pressure range: Select a sensor with a pressure range that covers the expected operating conditions of the application. It’s important to consider not only the normal operating pressure but also potential overpressure conditions that may occur.

- Accuracy: Determine the required level of accuracy for the application and choose a sensor that meets or exceeds this requirement. Keep in mind that higher accuracy sensors may come at a higher cost.

- Temperature range: Ensure the sensor can maintain its performance over the entire temperature range of the operating environment. If necessary, choose a sensor with built-in temperature compensation to maintain accuracy in fluctuating temperatures.

- Output signal: Consider the output signal requirements of the system the sensor will be integrated into. Some applications may require a specific output signal type, such as a 4-20 mA current loop or a 0-5 V voltage signal.

- Environmental considerations: Select a sensor with appropriate ingress protection (IP) ratings and resistance to chemicals or corrosive materials, depending on the operating environment.

Conclusion

Strain gauge pressure sensors are versatile, accurate, and reliable devices that play an essential role in various applications across numerous industries. While they have some limitations, such as cost and vulnerability to electromagnetic interference, their benefits often outweigh these drawbacks. By carefully considering the specific requirements of an application and selecting the appropriate sensor, engineers can ensure accurate and reliable pressure measurements in a wide range of environments.