Stamped heatsinks are cost-effective, lightweight thermal solutions made by cutting and shaping metal sheets, ideal for efficient heat dissipation in various electronic devices.

Stamped Heatsink: An Overview and Its Applications

Introduction

As electronic devices continue to evolve, the need for effective thermal management solutions has become more crucial than ever. Heatsinks play an important role in dissipating heat generated by electronic components, ensuring that devices operate at safe temperatures and maintain their performance. One of the most common types of heatsinks in the industry is the stamped heatsink. In this article, we will explore the features, benefits, and applications of stamped heatsinks.

What is a Stamped Heatsink?

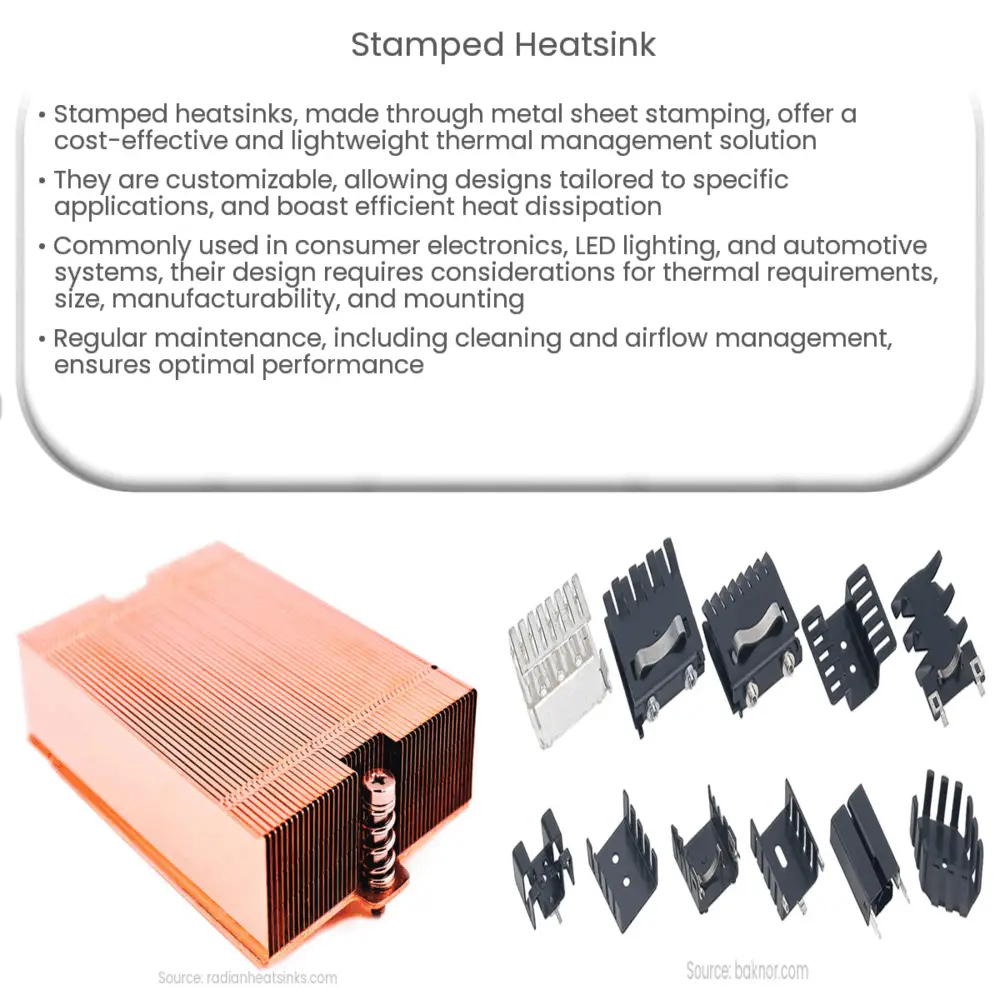

A stamped heatsink is a type of thermal solution that is made through the process of stamping, which involves cutting and forming a metal sheet into a desired shape. This process allows for the creation of heatsinks with complex geometries, as well as thinner and more efficient fins compared to other manufacturing methods, such as extrusion or machining.

Stamped heatsinks are typically made from metals with high thermal conductivity, such as aluminum or copper. The choice of material depends on various factors, including the desired thermal performance, weight, cost, and compatibility with the targeted application.

Advantages of Stamped Heatsinks

Stamped heatsinks offer several advantages over other types of heatsinks, including:

- Cost-effectiveness: The stamping process is generally more cost-effective than other manufacturing methods, particularly for large production volumes. This is because stamping can produce multiple heatsinks simultaneously with minimal material waste.

- Lightweight: Stamped heatsinks tend to be lighter than extruded or machined heatsinks due to their thinner fins and overall design. This can be particularly beneficial for applications where weight is a critical factor, such as in aerospace or portable devices.

- Customizable: The stamping process allows for the creation of heatsinks with a wide range of shapes and sizes, making it easier to design custom solutions tailored to specific applications or requirements.

- Efficient heat dissipation: Stamped heatsinks can have a higher surface area-to-volume ratio compared to other types, which can result in more efficient heat transfer and improved thermal performance.

Applications of Stamped Heatsinks

Stamped heatsinks are widely used across various industries due to their versatility and cost-effectiveness. Some common applications include:

- Consumer electronics: Devices such as smartphones, laptops, and gaming consoles often use stamped heatsinks to manage heat generated by high-performance processors and other components.

- LED lighting: Stamped heatsinks are frequently used in LED lighting fixtures to dissipate heat generated by the diodes, which helps to maintain the performance and lifespan of the LEDs.

- Automotive: Stamped heatsinks can be found in various automotive applications, such as engine control modules, infotainment systems, and electric vehicle battery management systems, to ensure proper thermal management.

Design Considerations for Stamped Heatsinks

When designing a stamped heatsink, several factors must be taken into account to ensure optimal performance and compatibility with the intended application. Some key considerations include:

- Thermal requirements: The heatsink must be designed to effectively dissipate the heat generated by the electronic components, while maintaining a safe operating temperature. This involves selecting an appropriate material, fin geometry, and overall design that meets the specific thermal needs of the application.

- Size and weight constraints: In many applications, space and weight limitations may dictate the design of the stamped heatsink. Designers must balance the need for effective heat dissipation with the constraints imposed by the device or system in which the heatsink will be used.

- Manufacturability: The stamping process can produce complex geometries, but certain designs may be difficult or costly to manufacture. Designers must consider the manufacturability of their heatsink designs and work closely with manufacturers to ensure that the final product can be produced cost-effectively and at scale.

- Mounting and assembly: The heatsink must be designed for easy integration with the electronic components and overall system. This may involve selecting appropriate mounting methods, such as clips, screws, or adhesives, and ensuring that the heatsink can be easily installed and removed for maintenance or replacement.

Maintaining and Optimizing Stamped Heatsink Performance

Proper maintenance and optimization of stamped heatsinks are crucial for ensuring their continued effectiveness in dissipating heat. Some tips for maintaining and optimizing heatsink performance include:

- Regular cleaning: Dust and debris can accumulate on the heatsink fins over time, reducing their ability to dissipate heat. Regular cleaning of the heatsink can help maintain its performance and prevent potential overheating issues.

- Thermal interface material (TIM): The use of a high-quality thermal interface material between the heatsink and the electronic component can significantly improve heat transfer, thereby enhancing the overall performance of the heatsink.

- Airflow management: Proper airflow is essential for efficient heat dissipation. Ensuring that the device or system housing the heatsink has adequate ventilation and airflow can help maintain optimal heatsink performance.

- Monitoring and diagnostics: Regularly monitoring the temperature of the electronic components and the heatsink can help identify potential issues before they become critical. This may involve using temperature sensors or thermal imaging to assess the performance of the heatsink and take corrective action if necessary.

Conclusion

Stamped heatsinks offer a cost-effective, lightweight, and customizable solution for thermal management in a wide range of applications, from consumer electronics to automotive systems. By understanding the advantages, applications, and design considerations associated with stamped heatsinks, engineers and designers can develop effective thermal management strategies that ensure the reliability and performance of their electronic devices and systems.