A solenoid actuator is an electromechanical device that converts electrical energy into linear motion, widely used in automotive, industrial, medical, and home appliances.

Solenoid Actuator: A Comprehensive Guide

Introduction to Solenoid Actuators

A solenoid actuator is an electromechanical device that converts electrical energy into linear mechanical motion. It is a fundamental component in various applications, including automotive, aerospace, industrial automation, medical equipment, and home appliances. The solenoid actuator offers numerous advantages, such as precise control, rapid response, and long service life, making it a popular choice for a wide range of applications.

Working Principle of Solenoid Actuators

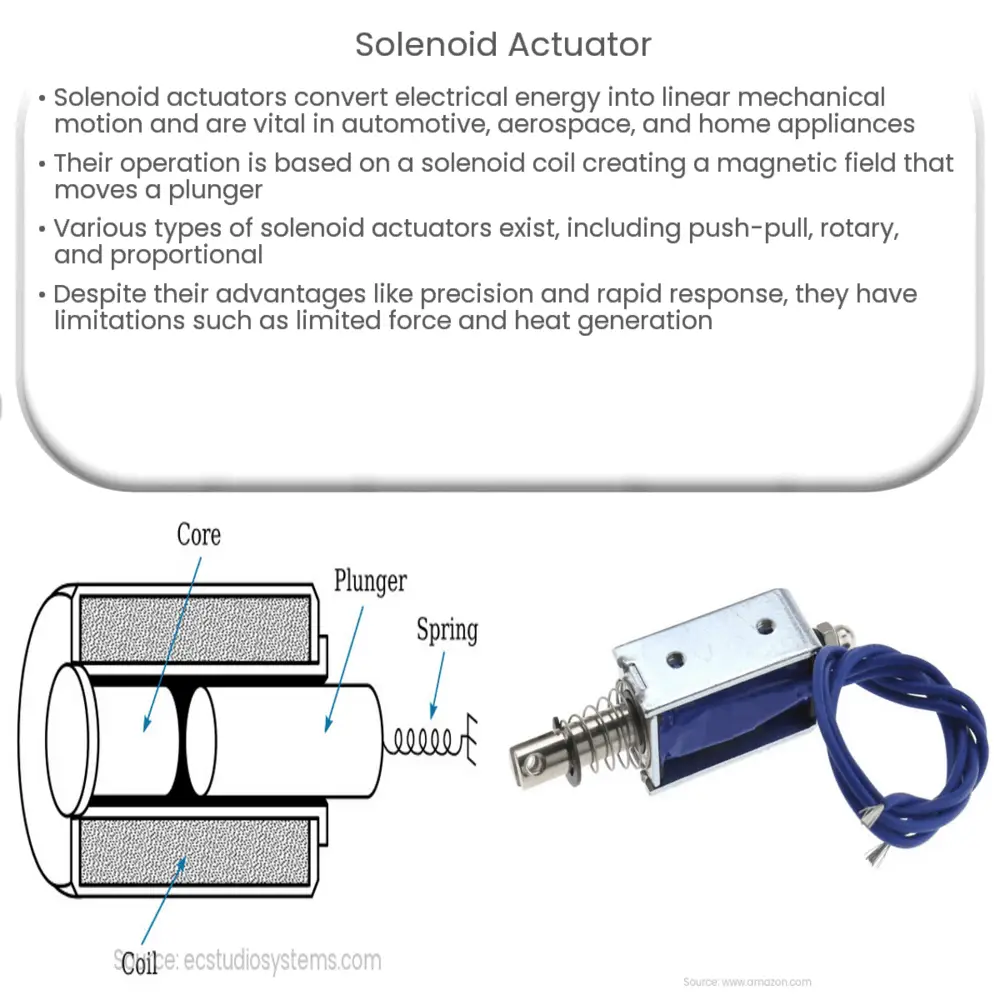

At the heart of the solenoid actuator is a solenoid coil, which is essentially a wound copper wire. When an electric current flows through the coil, it generates a magnetic field around the coil. This magnetic field interacts with a ferromagnetic plunger or armature, which is positioned within the coil. The resulting magnetic force causes the plunger to move linearly, either pushing or pulling, depending on the design of the actuator.

When the electrical current is turned off, the magnetic field dissipates, and the plunger returns to its original position due to an external force, such as a spring. This process can be repeated to generate continuous linear motion, allowing the solenoid actuator to perform various tasks, such as opening and closing valves, controlling the flow of fluid, or positioning components in machines.

Types of Solenoid Actuators

There are several types of solenoid actuators, each with its unique characteristics and applications. The most common types include:

1. Push-Pull Solenoid Actuators

Push-pull solenoid actuators are the simplest and most common type of solenoid actuators. They consist of a solenoid coil, a plunger, and a spring. When energized, the plunger is either pushed or pulled linearly. The spring is used to return the plunger to its original position when the current is turned off.

2. Rotary Solenoid Actuators

Rotary solenoid actuators convert the linear motion of the solenoid into rotary motion, typically through a mechanical linkage or gears. These actuators are commonly used in applications that require precise control of angular position, such as valve control or robotics.

3. Proportional Solenoid Actuators

Proportional solenoid actuators allow for variable control of the plunger’s position based on the input current. By varying the current, the position of the plunger can be controlled accurately, allowing for precise control in applications such as flow control valves or metering pumps.

4. Latching Solenoid Actuators

Latching solenoid actuators use permanent magnets to maintain the plunger’s position even when the current is turned off. This allows for a reduced power consumption, making them suitable for battery-operated devices or applications where energy efficiency is critical.

Advantages of Solenoid Actuators

Solenoid actuators offer several advantages over other types of actuators, such as hydraulic or pneumatic systems. Some of these benefits include:

- High precision and accuracy

- Fast response times

- Long service life and low maintenance

- Compact and lightweight design

- Cost-effectiveness

- Limited force and stroke length

- Heat generation due to coil resistance

- Potential for electromagnetic interference

- Noisy operation in some applications

- Force and stroke length requirements

- Operating voltage and current

- Operating temperature range

- Duty cycle

- Environmental factors, such as humidity and corrosion resistance

- Mounting and installation requirements

- Automotive: Door locks, fuel injectors, and transmission control

- Aerospace: Aircraft landing gear, flight control surfaces, and valve control

- Industrial Automation: Conveyor systems, robotics, and packaging equipment

- Medical Equipment: Drug delivery systems, patient positioning, and diagnostic devices

- Home Appliances: Washing machines, dishwashers, and refrigerators

Disadvantages of Solenoid Actuators

Despite their numerous advantages, solenoid actuators also have some limitations. Some of these drawbacks include:

Key Considerations for Selecting a Solenoid Actuator

When choosing a solenoid actuator for a specific application, several factors must be taken into account. These factors include:

Common Applications of Solenoid Actuators

Solenoid actuators are used in a wide variety of applications across different industries, including:

Conclusion

Solenoid actuators are an essential component in a wide range of applications due to their precision, rapid response, and long service life. They are versatile and adaptable, making them a popular choice for designers and engineers. By understanding the working principle, types, advantages, and limitations of solenoid actuators, one can select the most suitable actuator for their specific application. As technology continues to advance, solenoid actuators will undoubtedly play an increasingly important role in the development of new and innovative products and systems.