Rotary solenoids convert electrical energy into precise rotational motion, used in various industries for valve actuation, locking mechanisms, and more.

Understanding Rotary Solenoids: An In-Depth Guide

Introduction

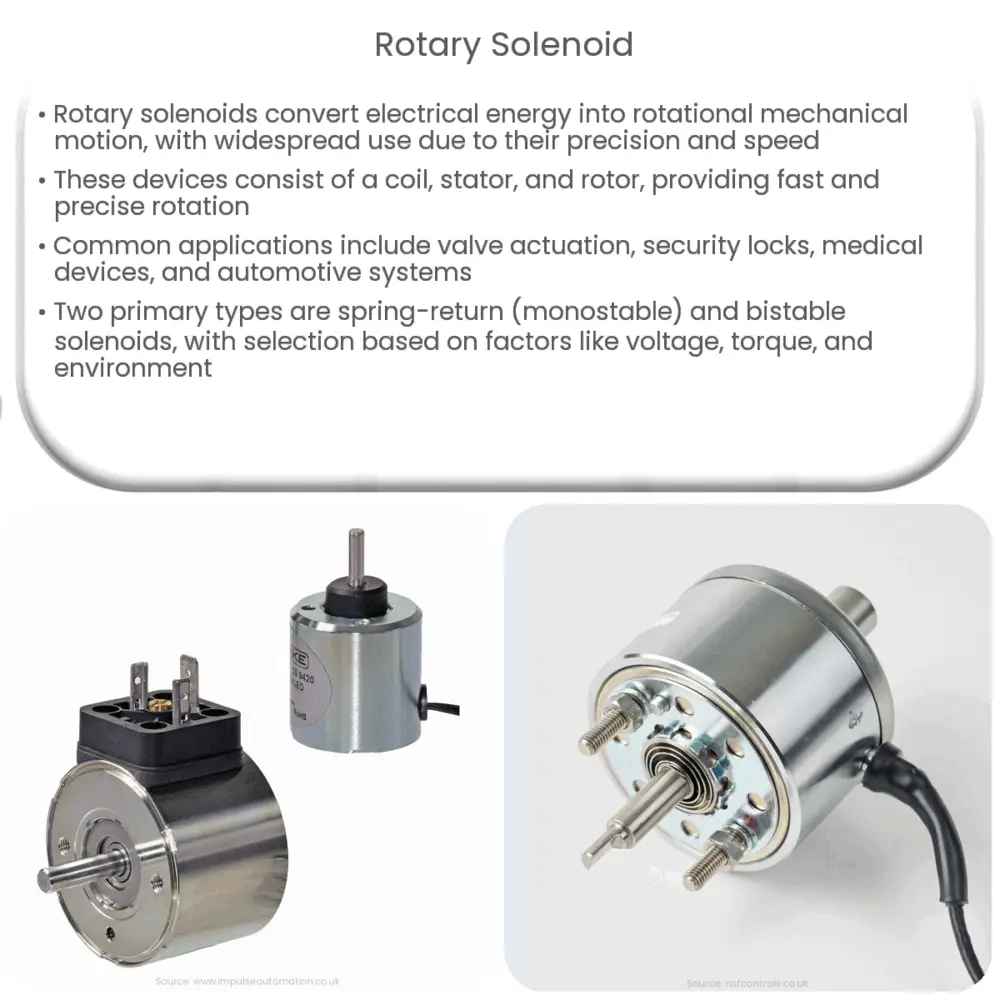

Rotary solenoids are electromechanical devices that convert electrical energy into mechanical motion, specifically rotational motion. They are commonly used in various industries due to their reliability, speed, and precision. In this article, we will explore the fundamentals of rotary solenoids, their applications, and the different types available in the market.

What is a Rotary Solenoid?

A rotary solenoid is an electromagnetic device that generates a rotary motion in response to an electrical current. It consists of a coil, a stator, and a rotor. The coil generates a magnetic field when an electrical current is applied to it. This magnetic field interacts with the stator and rotor, causing the rotor to rotate around its axis.

One key advantage of rotary solenoids is their ability to provide fast and precise rotational motion. They are often preferred over other types of motors, such as stepper motors and servo motors, in applications where high speed and accuracy are required.

Applications of Rotary Solenoids

Rotary solenoids find applications across various industries due to their versatility and efficiency. Some common applications include:

- Valve Actuation: Rotary solenoids are often used to control the opening and closing of valves in fluid control systems, such as those in HVAC systems and industrial automation.

- Locking Mechanisms: In security systems and devices, rotary solenoids can be employed to engage or disengage locking mechanisms, offering a quick and reliable means of access control.

- Medical Devices: Due to their precision and reliability, rotary solenoids are employed in various medical devices, such as syringe pumps and automated drug dispensers.

- Automotive Applications: Rotary solenoids are used in various automotive systems, including transmission control, throttle control, and fuel injection systems.

Types of Rotary Solenoids

There are two main types of rotary solenoids based on their design and operating principles: spring-return rotary solenoids and bistable rotary solenoids.

Spring-Return Rotary Solenoids

Spring-return rotary solenoids, also known as “monostable” solenoids, are designed to return to their original position when the electrical current is removed. They have a built-in spring mechanism that provides the necessary force to bring the rotor back to its starting position. This type of rotary solenoid is commonly used in applications where the solenoid is required to perform a single action and then return to its original state, such as valve actuation or locking mechanisms.

Bistable Rotary Solenoids

Bistable rotary solenoids, also known as “latching” solenoids, are designed to hold their position even when the electrical current is removed. These solenoids have two stable positions, typically 0 degrees and a predefined angle (e.g., 90 degrees). They are able to maintain their position without continuous electrical input, thanks to the magnetic properties of their components. Bistable rotary solenoids are commonly used in applications where energy efficiency is critical, such as battery-powered devices and systems that require long-term positioning.

Selecting the Right Rotary Solenoid

When choosing a rotary solenoid for a specific application, several factors must be considered to ensure optimal performance and reliability. Some of these factors include:

- Operating Voltage and Current: It is crucial to select a solenoid with an appropriate operating voltage and current for your application to prevent overheating and ensure proper functioning.

- Rotational Angle: Depending on the application, the required rotational angle of the solenoid may vary. Ensure that the solenoid you choose can provide the necessary angular displacement.

- Torque Requirements: The solenoid must generate enough torque to perform the desired task. Consider the torque requirements of your application when selecting a rotary solenoid.

- Operating Environment: The environment in which the solenoid will be operating can affect its performance and lifespan. Factors such as temperature, humidity, and the presence of corrosive or abrasive substances should be considered when selecting a solenoid.

- Size and Weight Constraints: In some applications, space and weight limitations may dictate the choice of solenoid. Be sure to select a solenoid that fits within the constraints of your application.

Conclusion

Rotary solenoids are versatile electromechanical devices that offer fast, precise, and reliable rotational motion. With a wide range of applications across various industries, their importance cannot be overstated. By understanding the different types of rotary solenoids and the factors to consider when selecting one, you can ensure that you choose the ideal solenoid for your specific application.