Explore the functioning, types, applications, advantages, and disadvantages of resistive level sensors in various industries.

Introduction to Resistive Level Sensors

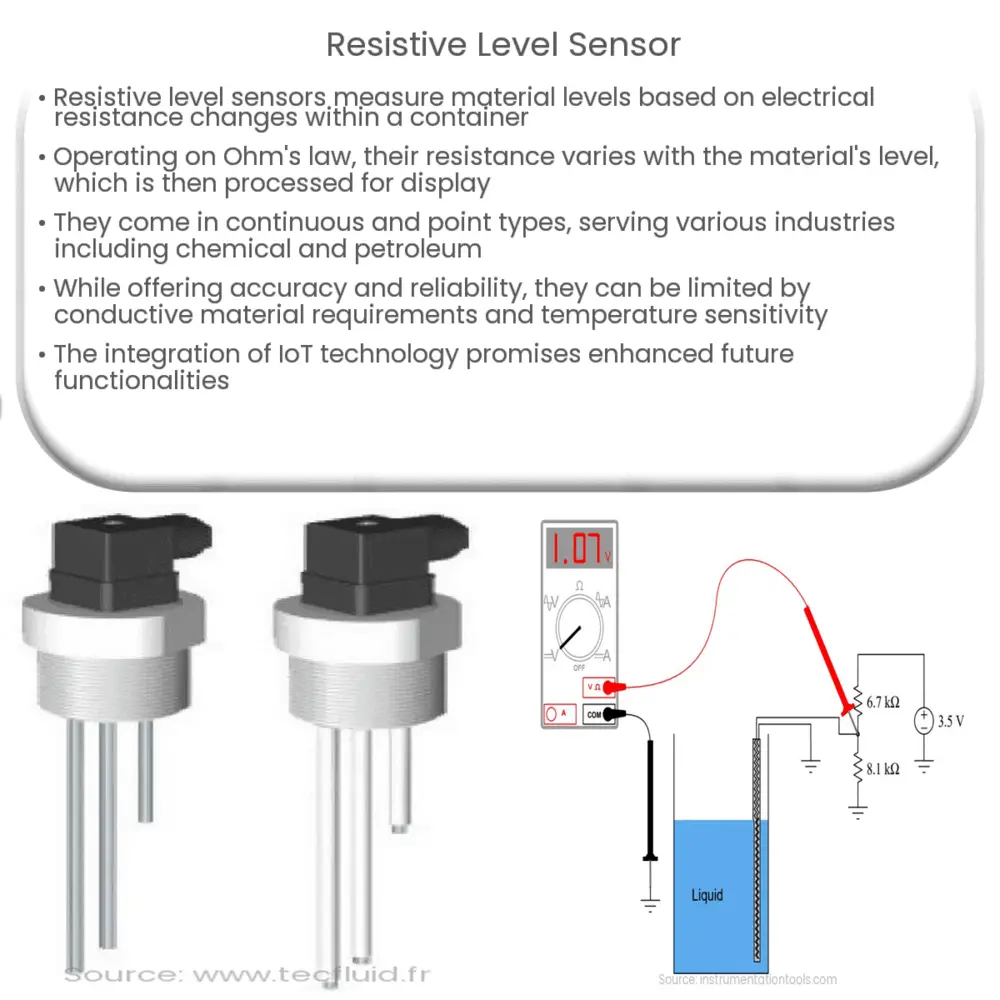

A resistive level sensor is a type of device used to measure the level of liquid or solid materials. Its function is rooted in the principles of electrical resistance, which changes according to the material’s level within a container or tank.

Principle of Operation

The resistive level sensor operates based on Ohm’s law, which states that the current flowing through a conductor is directly proportional to the voltage applied across it and inversely proportional to its resistance. The resistance changes as the level of the material in the tank changes, which is then measured to determine the level of the material.

Components of Resistive Level Sensors

Key components of a resistive level sensor include the following:

- Resistor: This element’s resistance changes according to the level of the material in the tank.

- Transducer: Transduces the resistance change into a readable output signal.

- Electronic circuit: Processes the transducer’s output signal and converts it into a format that can be read by a display unit or a control system.

Types of Resistive Level Sensors

There are two main types of resistive level sensors:

- Continuous Level Sensors: These sensors provide continuous real-time level measurement. They are commonly used in large industrial applications.

- Point Level Sensors: These sensors indicate whether the level of the material has reached a specific point. They are typically used in applications where overfill or underfill protection is needed.

Applications of Resistive Level Sensors

Resistive level sensors are widely used in various industries due to their accuracy and reliability. These industries include but are not limited to:

- Chemical industry: For measuring levels of corrosive and non-corrosive liquids.

- Petroleum industry: For level measurement of oil in reservoirs and tanks.

- Food and beverage industry: To monitor levels of various liquids during production processes.

- Water treatment plants: For monitoring the level of water in tanks and reservoirs.

Advantages and Disadvantages of Resistive Level Sensors

Like any other technology, resistive level sensors have their advantages and disadvantages. Understanding these can help in choosing the appropriate level sensor for a particular application.

Advantages

- Accurate and Reliable: Resistive level sensors provide accurate and reliable measurements, making them ideal for a wide range of applications.

- Unaffected by Material Properties: These sensors are not significantly affected by the changes in the properties of the material being measured, such as viscosity, density, and color.

- Easy to Install and Maintain: They require minimal maintenance and are easy to install, reducing the overall operational cost.

Disadvantages

- Limited to Conductive Materials: They are mostly suitable for conductive materials, limiting their application range.

- Sensitivity to Temperature: Changes in temperature can affect the sensor’s resistance, leading to inaccurate readings. This requires the use of a temperature compensation mechanism.

Choosing the Right Resistive Level Sensor

When selecting a resistive level sensor, certain factors need to be taken into consideration. These include the type of material to be measured, the required accuracy, the temperature and pressure conditions, the installation process, and the budget. A detailed analysis of these factors can guide the selection process towards the most suitable sensor for the application.

Future of Resistive Level Sensors

With the rapid advancements in technology, the functionality and efficiency of resistive level sensors continue to improve. The integration of Internet of Things (IoT) technology is opening up new possibilities for remote monitoring and control of level measurement systems, leading to improved process efficiency and reduced operational costs.

Conclusion

In conclusion, resistive level sensors are vital devices in many industries, enabling accurate and reliable level measurement of various materials. Despite their limitations, their advantages make them suitable for a wide range of applications. As technology continues to advance, we can anticipate even more accurate, efficient, and cost-effective resistive level sensors in the future.