A reed relay is a compact, fast-switching electromagnetic switch with a long lifespan, commonly used in telecommunications, test equipment, medical devices, and automotive applications.

Reed Relay: An Overview and Applications

Introduction

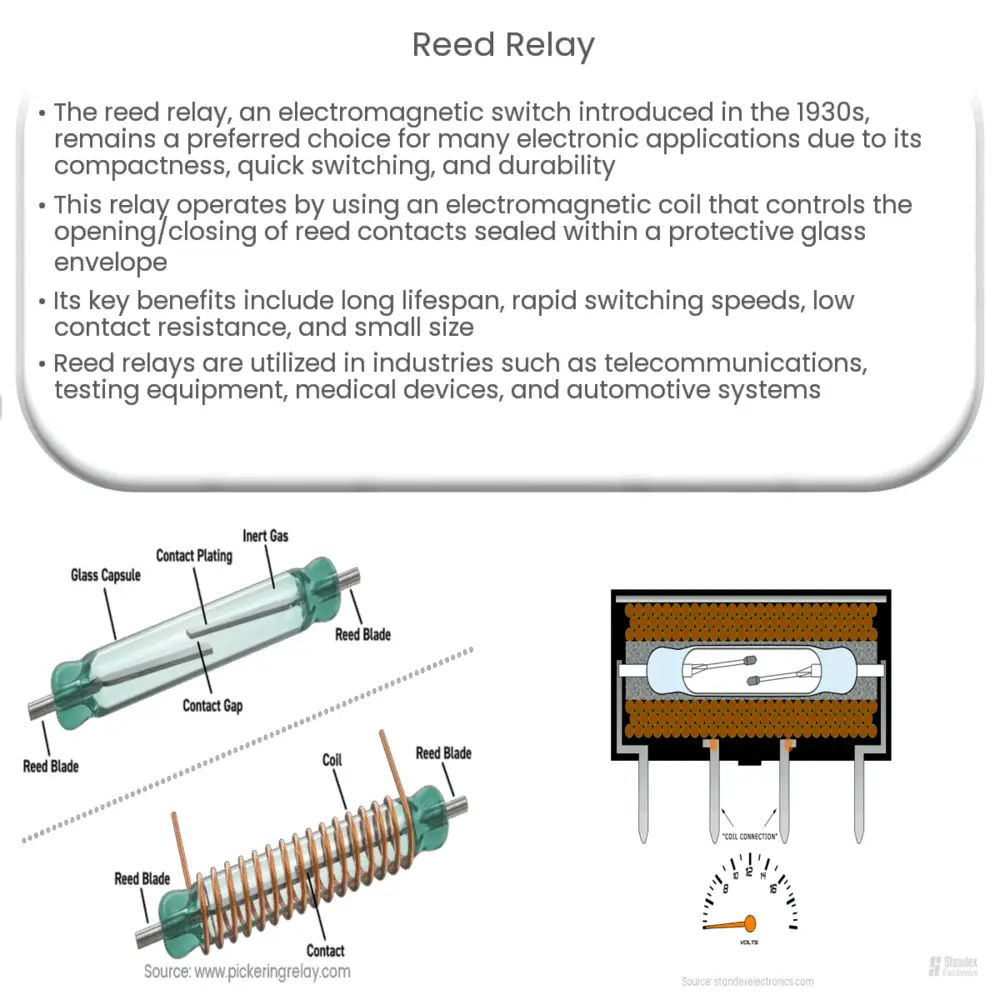

The reed relay, a type of electromagnetic switch, has been a critical component in various electronic applications since its invention in the 1930s. Known for its compact size, fast switching speed, and long life, the reed relay has withstood the test of time and remains a popular choice among engineers and designers alike. In this article, we will explore the inner workings of a reed relay, its advantages, and its common applications.

What is a Reed Relay?

A reed relay is an electrical switch that operates by using an electromagnetic coil to control the opening and closing of reed contacts. These contacts, typically made of ferromagnetic materials like nickel-iron alloys, are hermetically sealed within a protective glass envelope. The presence of an electric current in the coil generates a magnetic field that pulls the contacts together, allowing current to flow through the switch. When the current is removed, the magnetic field dissipates, and the contacts return to their original open state.

Advantages of Reed Relays

Reed relays offer several key advantages over other types of electrical switches, including:

- Long Lifespan: Due to their hermetically sealed construction, reed relays are not exposed to environmental factors like dust, moisture, or corrosive elements, which can degrade the performance of other types of switches. This enables them to have a longer operational life, often surpassing millions of switching cycles.

- Fast Switching Speeds: Reed relays can switch on and off in as little as a few microseconds, making them ideal for applications that require rapid signal processing or data transmission.

- Low Contact Resistance: The metallic reed contacts offer low contact resistance, which minimizes power loss and ensures reliable signal transmission.

- Compact Size: Due to their simple construction and small size, reed relays can be easily incorporated into space-constrained designs.

Common Applications of Reed Relays

Reed relays can be found in a wide range of applications across various industries. Some of the most common uses include:

- Telecommunications: Reed relays are often used in telephone exchanges, data transmission equipment, and other communication systems for signal routing and switching.

- Test and Measurement Equipment: The fast switching speeds and high reliability of reed relays make them well-suited for use in oscilloscopes, multimeters, and other test equipment.

- Medical Devices: Reed relays are frequently used in medical equipment such as patient monitoring systems and diagnostic devices, where their compact size and reliability are essential.

- Automotive: Reed relays are often incorporated into automotive systems for controlling functions like fuel injection, ignition, and safety features.

Types of Reed Relays

There are several types of reed relays, each designed to meet specific application requirements. Some of the most common types include:

- Single Pole, Single Throw (SPST): These relays have one input and one output, making them the simplest type of reed relay. They are commonly used for basic on/off switching tasks.

- Single Pole, Double Throw (SPDT): SPDT relays have one input and two outputs, allowing them to switch between two different circuits. This configuration is useful in applications where a signal must be routed to one of two destinations.

- Double Pole, Single Throw (DPST): With two inputs and two outputs, DPST relays can control two separate circuits simultaneously. These relays are often used in applications that require redundant or fail-safe operation.

- Double Pole, Double Throw (DPDT): These relays have two inputs and four outputs, enabling them to switch between two pairs of circuits. DPDT relays are typically used in more complex control systems.

Selection Criteria for Reed Relays

When choosing a reed relay for a specific application, several factors must be considered:

- Coil Voltage: The coil voltage determines the amount of electrical energy required to operate the relay. Selecting a relay with an appropriate coil voltage is crucial to ensure compatibility with the rest of the circuit.

- Contact Rating: The contact rating indicates the maximum current and voltage that the reed relay can safely handle. It is essential to choose a relay with a contact rating that matches the requirements of the application to prevent damage or failure.

- Switching Time: The switching time of a reed relay is the time it takes for the contacts to close or open in response to a change in coil current. This parameter is especially important in applications that require rapid switching, such as data transmission or test equipment.

- Insulation Resistance: Insulation resistance is a measure of the electrical isolation between the coil and contacts. A higher insulation resistance indicates a lower risk of electrical leakage or interference, which is crucial in sensitive applications.

Conclusion

Reed relays have proven to be a versatile and reliable solution for a variety of applications across numerous industries. Their compact size, fast switching speeds, and long operational life make them an attractive choice for designers and engineers. By understanding the different types of reed relays and considering the essential selection criteria, users can effectively integrate these robust switches into their projects, ensuring optimal performance and reliability.