A planar diode is a thin, flat semiconductor diode with enhanced performance, used in applications like power supplies and signal processing.

Understanding the Planar Diode: Principles and Applications

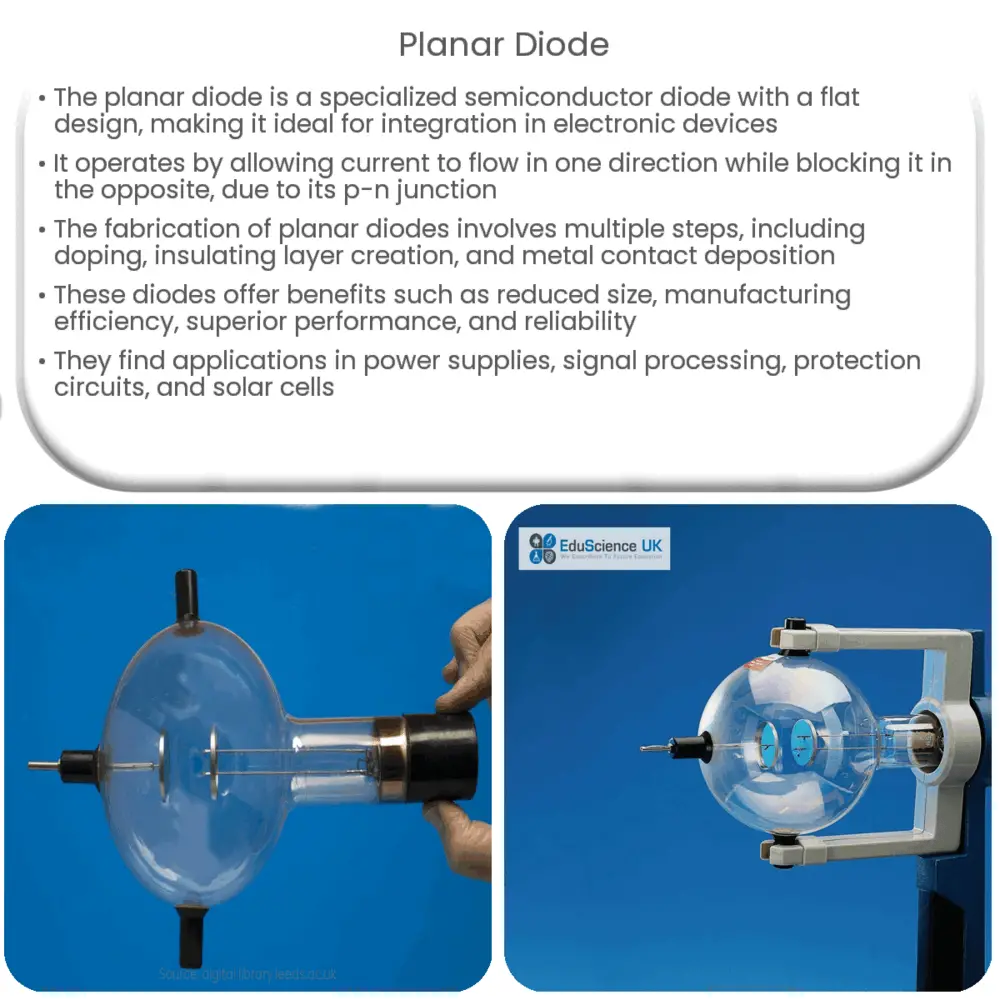

A planar diode is a specific type of semiconductor diode that features a planar design, enabling its use in a wide range of electronic devices. This article aims to provide a comprehensive overview of the principles behind planar diodes, their fabrication process, and their various applications in modern electronics.

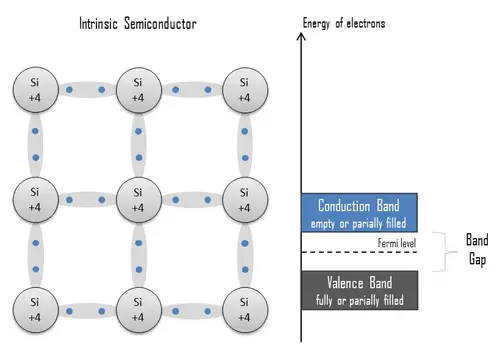

Principles of Planar Diodes

A diode is an electronic component that allows current to flow in one direction while blocking it in the opposite direction. The basic structure of a diode consists of two regions made from semiconductor materials, typically silicon, which are doped with different impurities to create a p-n junction. The p-type region contains an excess of positive charge carriers (holes), while the n-type region has an excess of negative charge carriers (electrons). When a voltage is applied across the diode, the current flows from the p-type to the n-type region if the voltage is positive (forward-biased), and the current is blocked if the voltage is negative (reverse-biased).

The planar diode is a specialized design of the traditional diode, where the p-n junction is created through a planar process. This design offers several advantages, including improved manufacturing efficiency, reduced size, and enhanced performance characteristics. Planar diodes are characterized by their thin and flat design, allowing them to be integrated into circuits easily and facilitating the miniaturization of electronic devices.

Fabrication Process of Planar Diodes

The fabrication of planar diodes is achieved through a series of steps, beginning with the creation of a silicon wafer substrate. This substrate acts as the base for the diode, and its surface is typically polished to minimize defects and ensure a smooth interface for the subsequent layers.

The next step involves the doping process, which introduces impurities into the silicon substrate to create the p-type and n-type regions. This is typically done using ion implantation or diffusion methods. After the doping process, a thin insulating layer, such as silicon dioxide, is grown on the surface of the substrate to act as a barrier between the semiconductor material and the metal contacts that will be added later.

A photolithography process is then used to create a pattern on the insulating layer, which will define the areas where the metal contacts will be deposited. This pattern is transferred onto the insulating layer using a photoresist material and ultraviolet light exposure. Once the pattern is in place, a metal layer, usually aluminum or gold, is deposited onto the exposed regions, forming the electrical contacts for the diode. Finally, the excess metal and photoresist material are removed, and the planar diode is complete.

Advantages of Planar Diodes

Planar diodes offer several benefits over their conventional counterparts, making them an attractive choice for a variety of electronic applications. Some of these advantages include:

- Size: Due to their thin and flat design, planar diodes occupy less space, allowing for higher integration density in electronic devices and enabling the development of smaller and more compact circuits.

- Manufacturing Efficiency: The planar process used in fabricating these diodes is well-suited for large-scale production, as it allows for the creation of multiple diodes on a single silicon wafer. This translates into lower production costs and increased yield.

- Performance: Planar diodes exhibit superior performance characteristics, such as lower leakage current, faster switching times, and reduced capacitance. These attributes make them ideal for high-speed and high-frequency applications.

- Reliability: The planar design and fabrication process contribute to improved reliability and longer operational lifetimes for the diodes, due to the reduced likelihood of defects and minimized stress on the p-n junction.

Applications of Planar Diodes

Planar diodes are used in a wide range of electronic devices and applications, owing to their versatile nature and advantageous properties. Some common applications include:

- Power Supplies: Planar diodes are commonly used in rectifier circuits to convert alternating current (AC) to direct current (DC), ensuring a stable power supply for electronic devices.

- Signal Processing: The high-speed switching capabilities of planar diodes make them suitable for use in signal processing applications, such as frequency mixers and demodulators in communication systems.

- Protection Circuits: Planar diodes can be employed in protection circuits to prevent damage from voltage surges, electrostatic discharge, and reverse voltage conditions.

- Solar Cells: Planar diodes are often integrated into solar cells to minimize power losses due to shading and to enhance the overall efficiency of the photovoltaic system.

In conclusion, planar diodes have become an essential component in modern electronics, thanks to their unique design, fabrication process, and advantageous characteristics. Their widespread use in various applications, from power supplies to signal processing, highlights their versatility and importance in the development of compact and efficient electronic devices.