Piezoelectric current sensors offer accurate measurement and control in various applications, with high sensitivity, wide bandwidth, and immunity to electromagnetic interference.

Piezoelectric Current Sensor: Harnessing the Power of Piezoelectricity

Introduction

In recent years, there has been a growing interest in the development of efficient and accurate current sensors to meet the increasing demand for precise monitoring and control of electrical systems. One innovative technology that has emerged as a promising solution is the piezoelectric current sensor. This article aims to introduce the principles behind the piezoelectric effect and explore the advantages, applications, and challenges of using piezoelectric current sensors in various industries.

Understanding the Piezoelectric Effect

The piezoelectric effect is a fascinating phenomenon in which certain materials generate an electric charge in response to mechanical stress or deformation. This unique property was first discovered in 1880 by French physicists Jacques and Pierre Curie, who observed that quartz crystals produced an electric voltage when subjected to mechanical pressure. Since then, a wide range of piezoelectric materials has been identified, including ceramics, crystals, and certain polymers.

There are two primary effects associated with piezoelectricity: the direct piezoelectric effect and the converse piezoelectric effect. The direct effect refers to the generation of an electric charge when a material is mechanically stressed, while the converse effect involves the material undergoing mechanical deformation when an electric field is applied. Both of these effects have been harnessed to develop a variety of sensors, actuators, and transducers for numerous applications.

Piezoelectric Current Sensors: How They Work

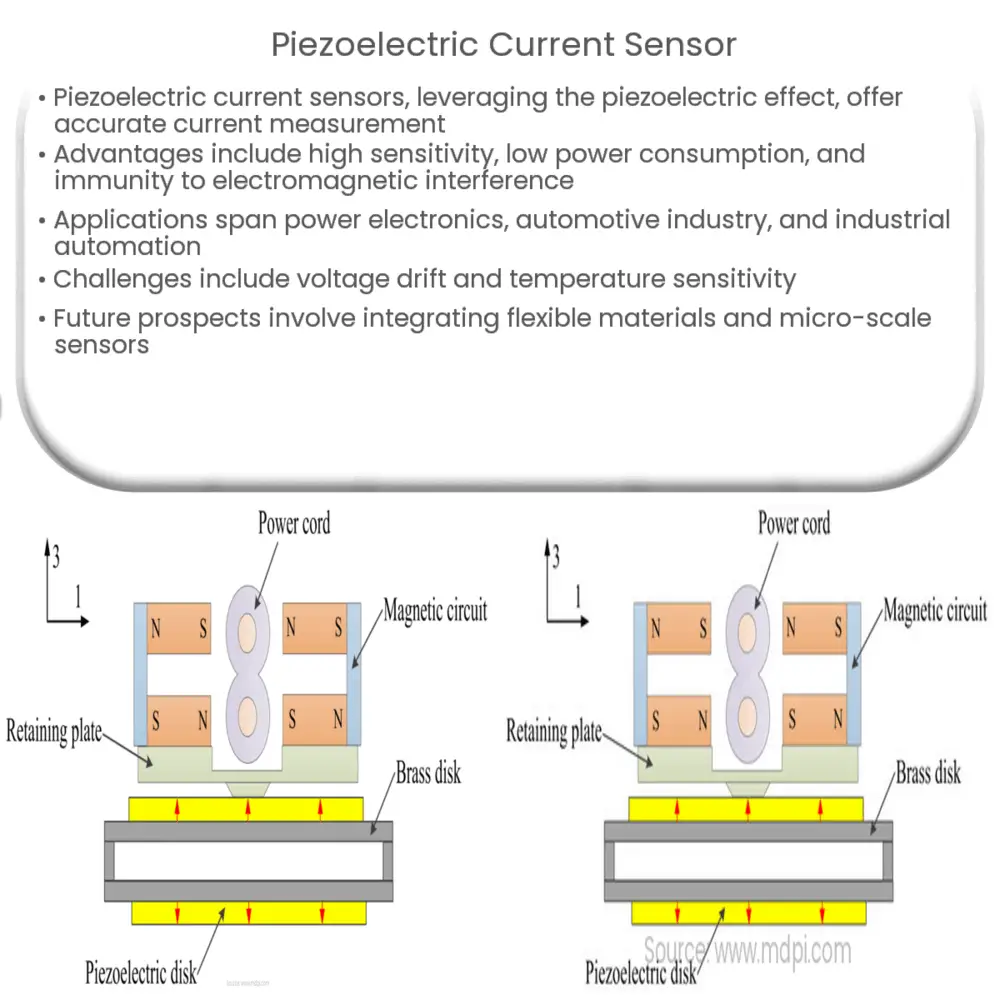

A piezoelectric current sensor operates based on the direct piezoelectric effect. When a current-carrying conductor, such as a wire, experiences a magnetic field, it generates a mechanical force called the Lorentz force. This force causes the conductor to vibrate or deform, which in turn produces mechanical stress on the piezoelectric material. The material then generates an electrical charge proportional to the applied stress, which can be measured and converted into a corresponding current value.

These sensors offer several advantages over traditional current sensing methods, such as the Hall effect and current transformers. Some of the key benefits include high sensitivity, wide bandwidth, excellent linearity, low power consumption, and the ability to measure both AC and DC currents. Additionally, due to their inherent galvanic isolation, piezoelectric current sensors are immune to electromagnetic interference, making them well-suited for use in electrically noisy environments.

Applications of Piezoelectric Current Sensors

Piezoelectric current sensors have found use in a wide range of applications across various industries. Some common examples include:

- Power electronics: Accurate current measurement is critical for the efficient operation and control of power electronic devices, such as inverters, converters, and motor drives. Piezoelectric current sensors can help optimize performance, increase energy efficiency, and prevent potential failures in these systems.

- Automotive industry: With the rise of electric and hybrid vehicles, the need for reliable current sensing solutions has become increasingly important. Piezoelectric sensors can be used to monitor battery charging and discharging, as well as inverter and motor control systems.

- Industrial automation: These sensors can be integrated into various industrial machines and processes to provide real-time current monitoring, enhancing overall system efficiency and safety.

Challenges and Limitations

Despite the many advantages of piezoelectric current sensors, there are some challenges and limitations that need to be addressed. One significant concern is the drift in output voltage over time, which can be attributed to the charge leakage in piezoelectric materials. This phenomenon can lead to inaccurate current measurements, especially in long-term applications. Various methods have been developed to mitigate this issue, such as using advanced signal processing techniques and incorporating temperature compensation circuits.

Another limitation is the sensitivity of piezoelectric materials to temperature fluctuations, which can impact their performance and accuracy. Choosing materials with low temperature coefficients and incorporating temperature compensation methods can help alleviate these concerns.

Recent Developments and Future Outlook

Research and development in the field of piezoelectric current sensing continue to advance, with a focus on addressing existing challenges and expanding the range of potential applications. Some recent developments include the use of flexible piezoelectric materials, such as polyvinylidene fluoride (PVDF) and its copolymers, which can be integrated into wearable electronics and flexible systems.

Moreover, the ongoing miniaturization trend in electronics has spurred the development of micro-scale piezoelectric current sensors, which can be incorporated into increasingly compact devices and systems. Advances in materials science, such as the discovery of new piezoelectric materials with improved performance characteristics, are also expected to drive innovation in this field.

As our reliance on accurate current measurement and control continues to grow, piezoelectric current sensors are poised to play an increasingly important role in a wide range of industries. By overcoming existing challenges and leveraging the latest advancements in materials and technology, these sensors have the potential to revolutionize the way we monitor and manage electrical systems, ultimately contributing to greater energy efficiency, safety, and performance.

Conclusion

In conclusion, piezoelectric current sensors offer a promising solution for precise current measurement and control in various applications. Leveraging the unique properties of piezoelectric materials, these sensors provide numerous advantages over traditional methods, including high sensitivity, wide bandwidth, and immunity to electromagnetic interference. As research and development in this field continue to advance, piezoelectric current sensors are expected to play an increasingly important role in shaping the future of electrical system monitoring and management.