Explore the workings, benefits, types, and future prospects of Permanent Magnet Generators (PMGs), a cornerstone of sustainable energy solutions.

Introduction to Permanent Magnet Generators

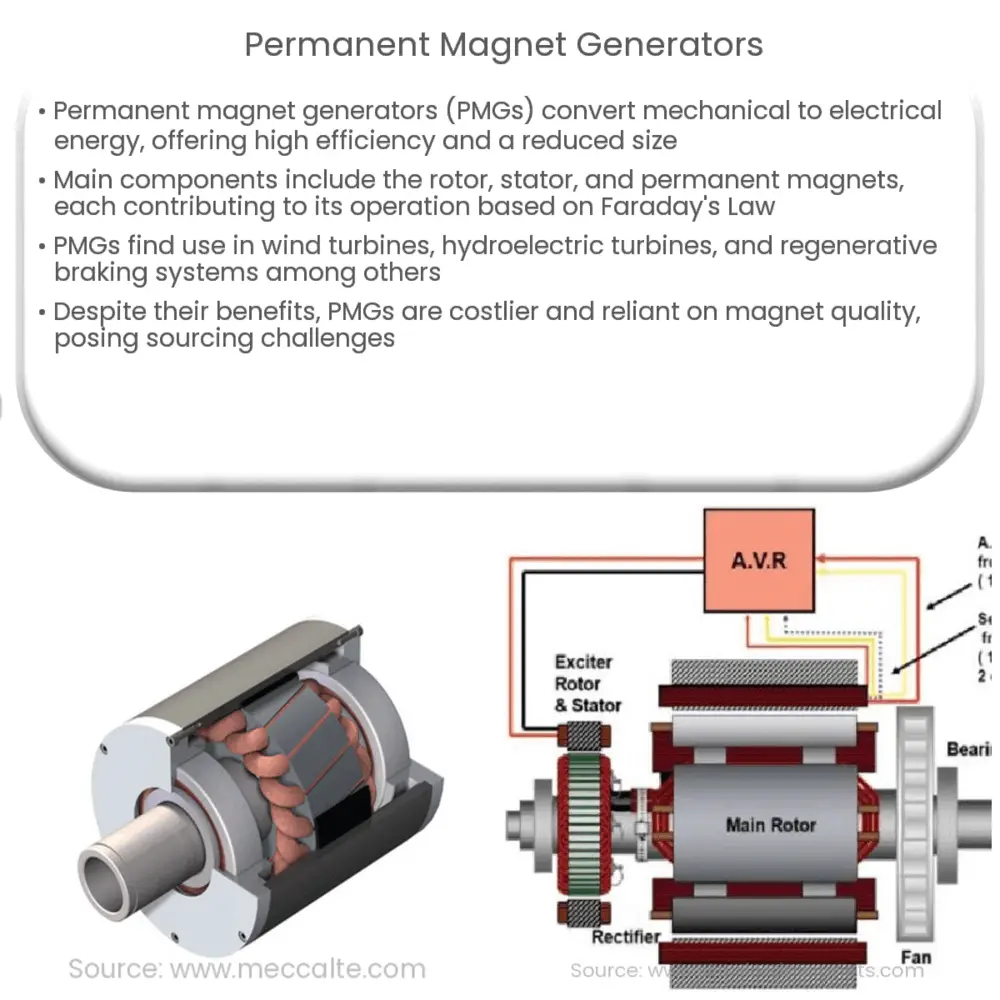

Permanent magnet generators, or PMGs, are a significant piece of technology with wide-ranging applications. Essentially, PMGs are devices that convert mechanical energy into electrical energy using permanent magnets, unlike traditional generators that use electromagnets. The workings of these generators are based on the principle of Faraday’s Law of electromagnetic induction.

Components of a Permanent Magnet Generator

A PMG chiefly comprises three main components: the rotor, the stator, and the permanent magnets. The rotor is the rotating component attached to the mechanical energy source, such as a wind turbine, while the stator is the stationary part that houses the coil or winding.

- The Rotor: The rotor is made from a magnetic material, and it’s designed to interact with the stator’s magnetic field when it spins. The arrangement and type of permanent magnets on the rotor directly influence the generator’s efficiency.

- The Stator: The stator includes the coil or winding, which is generally made up of copper or aluminum. It’s responsible for generating an electric current when the rotor’s magnetic field induces a change in its magnetic field.

- Permanent Magnets: The permanent magnets create a constant magnetic field. They’re typically made from rare-earth materials like neodymium or ferrite due to their strong magnetic properties.

Working Principle of a Permanent Magnet Generator

The basic operation of a PMG revolves around Faraday’s Law of electromagnetic induction. This law stipulates that a change in the magnetic field within a coil of wire induces an electromotive force (EMF) in the wire. In the context of a PMG, the rotor’s rotation causes the permanent magnets to move in relation to the stator, altering the magnetic field inside the coil or winding. This change induces an EMF, leading to the production of electric current.

Advantages of Permanent Magnet Generators

Permanent magnet generators offer several advantages over traditional generators. These include increased efficiency, reduced operational noise, and decreased size and weight for the same output power. The efficiency gains are particularly significant because the PMGs do not require any external power source for magnetization, reducing energy loss.

Applications of Permanent Magnet Generators

PMGs are used in a broad range of applications due to their robustness and high efficiency. Examples include wind turbines, hydroelectric turbines, and in vehicles for regenerative braking systems. They’re also popular in portable electronics and handheld power tools.

Types of Permanent Magnet Generators

There are different types of permanent magnet generators designed to suit various needs. These include:

- Direct-Drive PMGs: These types of generators are directly coupled to the mechanical energy source and operate at the same speed. They are commonly found in wind turbines due to their high efficiency and simplicity.

- Gear-Driven PMGs: These are generally used when the mechanical source operates at a speed that isn’t optimal for the generator. They use gears to adjust the rotational speed for efficient power generation.

- Radial and Axial Flux PMGs: These terms refer to the direction of the magnetic field. In radial flux generators, the magnetic field flows from the center of the rotor outwards, while in axial flux generators, the field runs parallel to the rotor’s axis.

The Future of Permanent Magnet Generators

With advancements in material science and the increasing demand for renewable energy sources, the importance of permanent magnet generators is likely to increase in the coming years. Researchers are continually striving to develop better and more efficient PMGs, especially with rare-earth magnets, despite the environmental and geopolitical challenges associated with their extraction.

Challenges and Limitations

Despite their many benefits, PMGs do have some limitations. They are generally more expensive than their traditional counterparts due to the cost of the permanent magnets. The performance of PMGs is also highly dependent on the quality of the magnets, which can degrade over time or due to high temperatures. Furthermore, obtaining the rare-earth materials used in high-performance PMGs poses both environmental and geopolitical challenges.

Conclusion

In conclusion, permanent magnet generators represent a significant technological innovation in energy conversion. Their high efficiency, versatility, and wide range of applications make them an attractive choice for many industries. However, there are challenges to overcome, particularly in terms of cost, magnet quality, and material sourcing. As research continues and technology progresses, we can expect to see even more efficient and cost-effective PMGs, contributing to a more sustainable and energy-efficient future.