Explore the fundamentals of Permanent Magnet DC Motors, their structure, benefits, limitations, and applications in our comprehensive guide.

Introduction to Permanent Magnet DC Motors

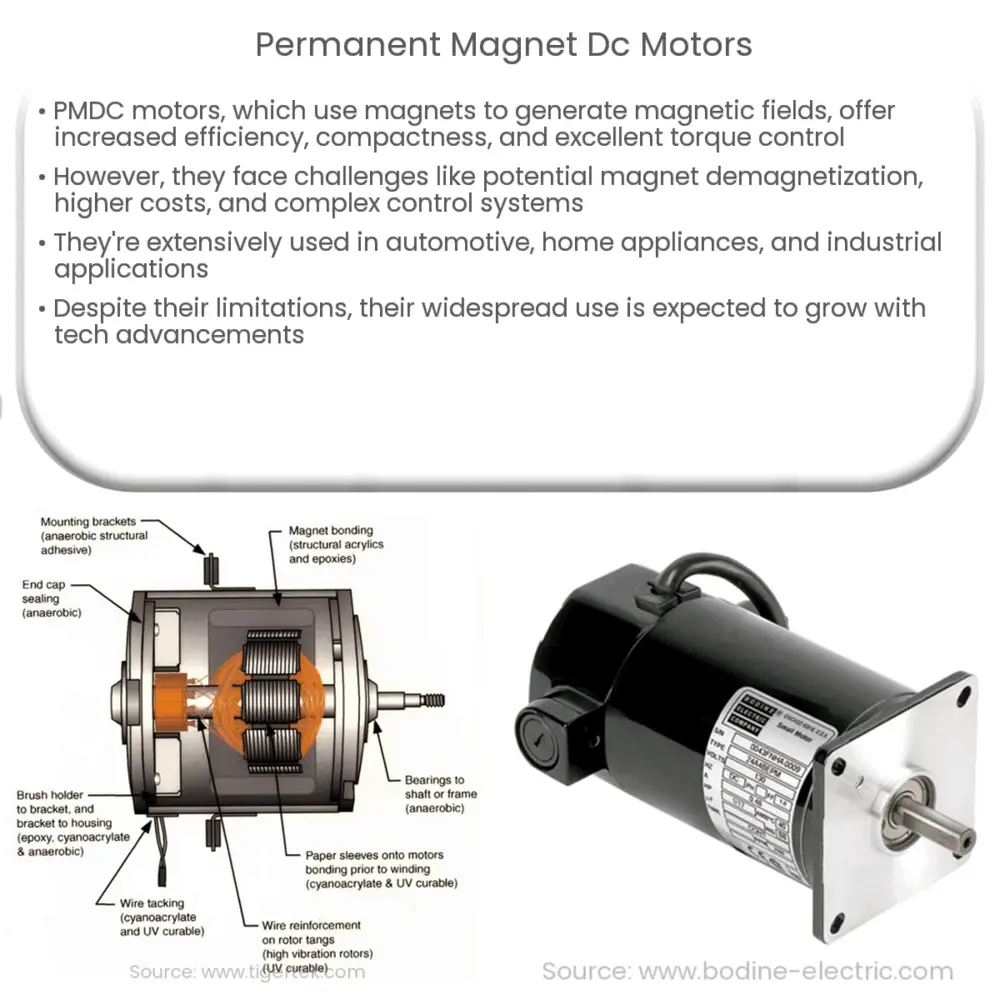

Permanent magnet direct current (DC) motors are a type of motor that uses magnets to generate the magnetic field instead of winding. This key distinction gives them unique benefits and applications. This article will cover the essentials about these important components of modern machinery.

Understanding the Basics of Permanent Magnet DC Motors

A permanent magnet DC motor (PMDC motor) is a type of DC motor that incorporates magnets in its design. Unlike a conventional DC motor that uses windings to generate the required magnetic field, a PMDC motor uses permanent magnets — hence its name. This results in a more compact and efficient design, albeit with some unique challenges.

Structure and Working Principle

A PMDC motor is essentially composed of two parts: the stator and the rotor. The stator is the stationary part of the motor that houses the permanent magnets, while the rotor, also known as the armature, is the rotating part where the windings are located.

- Stator: The stator contains permanent magnets, which are mounted on the inner periphery of the motor casing. These magnets create a constant magnetic field.

- Rotor: The rotor consists of windings wound on a core. When a DC supply is given, a current is produced in these windings, creating a magnetic field. This magnetic field interacts with the field from the stator, generating torque that causes the rotor to turn.

Advantages of Permanent Magnet DC Motors

There are numerous advantages of PMDC motors that make them highly sought after in several industries. Let’s delve into a few of these advantages:

- Efficiency: Since there is no need to induce a magnetic field in the stator, PMDC motors tend to be more efficient compared to their counterparts. This is because there is no power loss due to the magnetization of the stator.

- Compactness: The use of permanent magnets reduces the need for windings on the stator, which results in a smaller motor size for a given power output. This makes PMDC motors suitable for applications where space is a limitation.

- Speed and Torque: PMDC motors offer excellent speed control and high torque. This makes them ideal for applications where precise speed and torque control is required.

Disadvantages of Permanent Magnet DC Motors

Despite their many advantages, PMDC motors also have some limitations:

- Magnet Demagnetization: One of the main drawbacks is the risk of magnet demagnetization. This can occur due to high temperatures or a large external magnetic field, which can result in a loss of motor efficiency.

- Cost: Permanent magnets, especially those made from rare earth materials, can be expensive, which can increase the cost of the motor.

- Control Complexity: PMDC motors can require more complex control systems compared to their counterparts, especially in high power applications. This can make the design and implementation of these motors more challenging.

Applications of Permanent Magnet DC Motors

Thanks to their benefits, PMDC motors find extensive applications in a variety of fields:

- Automotive Applications: These motors are widely used in electric vehicles due to their high efficiency and compact size. They are also found in windshield wipers, power windows, and fan blowers.

- Home Appliances: PMDC motors are used in appliances such as mixers, vacuum cleaners, and washing machines where high torque and speed control are necessary.

- Industrial Applications: Due to their high power density and compactness, these motors are used in various industrial applications like conveyors, pumps, and lifts.

Conclusion

In conclusion, permanent magnet DC motors, with their high efficiency, compactness, and excellent torque and speed control capabilities, have become a pivotal part of many modern machinery and devices. Despite their few limitations, such as potential demagnetization and higher cost, the advantages they offer make them an attractive option for a variety of applications. As advancements in technology continue to improve their design and efficiency, their utilization is expected to grow even further in the years to come.