Explore the role and importance of motor voltage sensors, their types, technologies, selection factors, and future prospects in motor management.

Introduction to Motor Voltage Sensors

Motor voltage sensors are critical components in the world of electrical engineering and automation. These devices are designed to detect and monitor the voltage level in motor systems, providing crucial information that helps to ensure optimal performance and maintain the safety of the operations.

Understanding the Basics of Voltage

In order to fully comprehend the function and importance of motor voltage sensors, it’s essential to have a basic understanding of voltage itself. Voltage, often denoted by the letter ‘V’, is the electric potential difference between two points. It’s the driving force behind the flow of electric current in an electrical circuit.

The Role of Motor Voltage Sensors

Motor voltage sensors play a pivotal role in the operation of electric motors. These sensors continuously monitor the voltage supplied to the motor. This data is essential for various reasons, including:

- Maintaining Optimal Motor Performance: By continuously tracking the voltage levels, these sensors help to ensure that the motor is operating under the right conditions. This monitoring helps to prevent under or over-voltage situations that could harm the motor or decrease its efficiency.

- Protecting the Motor: Over-voltage can lead to overheating and potential damage to the motor. By instantly detecting any voltage anomalies, motor voltage sensors can initiate protective measures, like shutting down the motor, to prevent damage.

- Energy Efficiency: Efficient energy use is crucial in today’s world. Voltage sensors contribute to this by ensuring the motor only uses the necessary amount of power to operate, thereby avoiding unnecessary energy wastage.

Types of Motor Voltage Sensors

Motor voltage sensors come in various types, each designed to suit different applications and motor specifications. Here are some common types:

- AC Voltage Sensors: These sensors are designed for Alternating Current (AC) motors, where the voltage fluctuates in a sinusoidal pattern. These sensors can effectively track these fluctuations to ensure smooth motor operations.

- DC Voltage Sensors: Direct Current (DC) motors require DC voltage sensors, where the voltage level remains constant over time. These sensors are designed to effectively monitor these constant voltage levels.

- Multifunction Voltage Sensors: These versatile sensors can monitor both AC and DC voltage levels, providing a comprehensive solution for complex motor systems.

Voltage Sensor Technologies

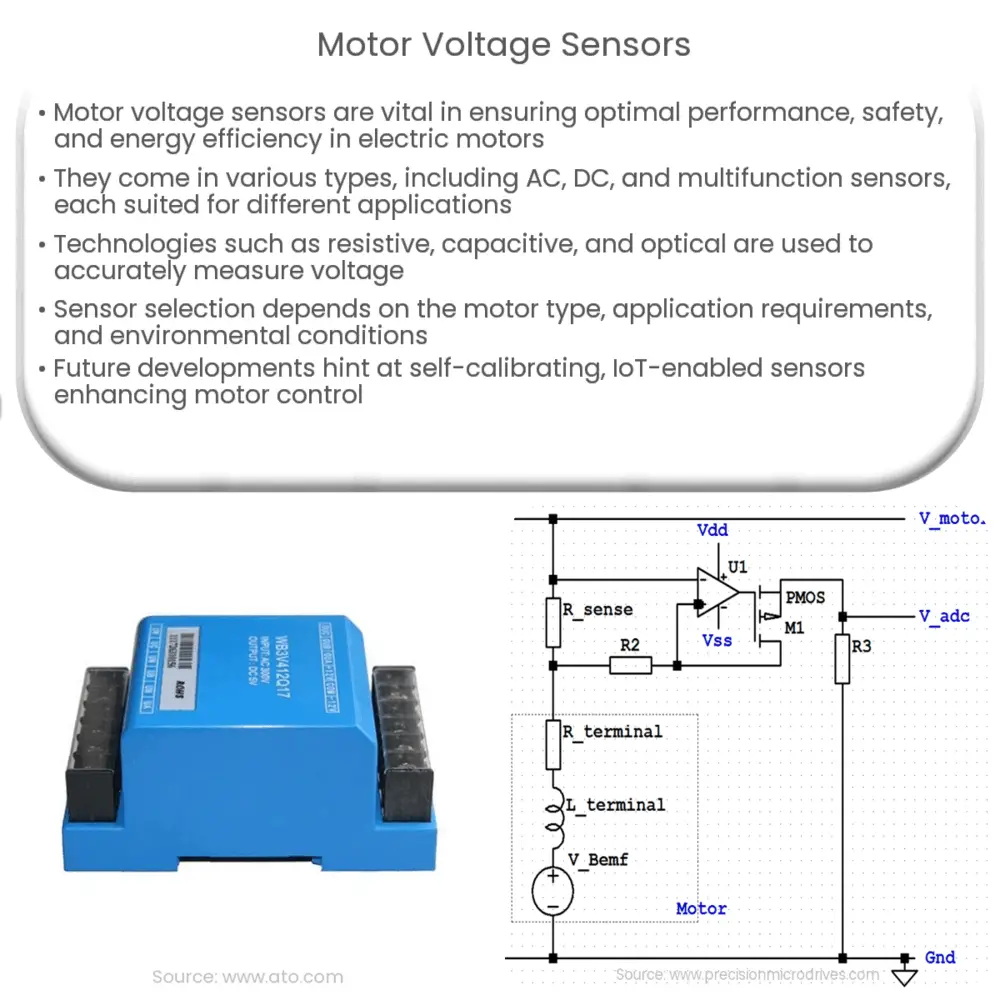

Motor voltage sensors employ various technologies to accurately measure voltage levels. These include:

- Resistive Voltage Sensors: These sensors use the voltage drop across a known resistor to determine the voltage level.

- Capacitive Voltage Sensors: These sensors employ the principle of capacitive voltage division to measure voltage.

- Optical Voltage Sensors: In these sensors, the voltage level is determined by measuring the electric field around the voltage source using optical methods.

These diverse technologies allow for flexibility in application and enhance the precision of voltage monitoring in electric motor systems.

Selecting the Right Motor Voltage Sensor

Selecting the appropriate voltage sensor for a particular motor system depends on various factors:

- Motor Type: The type of motor (AC or DC) primarily determines the choice of the sensor. AC motors require AC voltage sensors, while DC motors need DC voltage sensors.

- Application Requirements: The specific requirements of the application also play a crucial role in the selection process. For instance, a sensor with a higher voltage range might be needed for heavy-duty motors.

- Environmental Conditions: The conditions in which the motor operates, such as temperature, humidity, and dust, can affect the sensor’s performance. Therefore, it’s essential to choose a sensor that can withstand these conditions.

Installation and Maintenance

Proper installation and maintenance of motor voltage sensors are critical for their accurate functioning. It’s important to follow the manufacturer’s guidelines for installation to ensure optimal performance. Regular maintenance, including periodic checks and calibrations, can help extend the sensor’s life and maintain its accuracy.

The Future of Motor Voltage Sensors

With advancements in technology, motor voltage sensors are becoming smarter and more capable. The future holds promise for innovations such as self-calibrating sensors and IoT-enabled voltage sensors, which could revolutionize motor control and maintenance. By integrating with data analytics, these smart sensors could provide valuable insights into motor health and performance.

Conclusion

In conclusion, motor voltage sensors are integral components in the management and operation of electric motors. They play a vital role in maintaining optimal performance, protecting the motor, and enhancing energy efficiency. With an understanding of voltage and the different types of voltage sensors, we can appreciate the critical role these devices play. The future of these sensors is exciting, as advancements in technology promise to make them smarter and more efficient, adding a new dimension to the realm of motor control and maintenance.