Explore the importance of motor overload protection devices, their types, selection process, maintenance, and legal standards in our comprehensive guide.

Introduction to Motor Overload Protection Devices

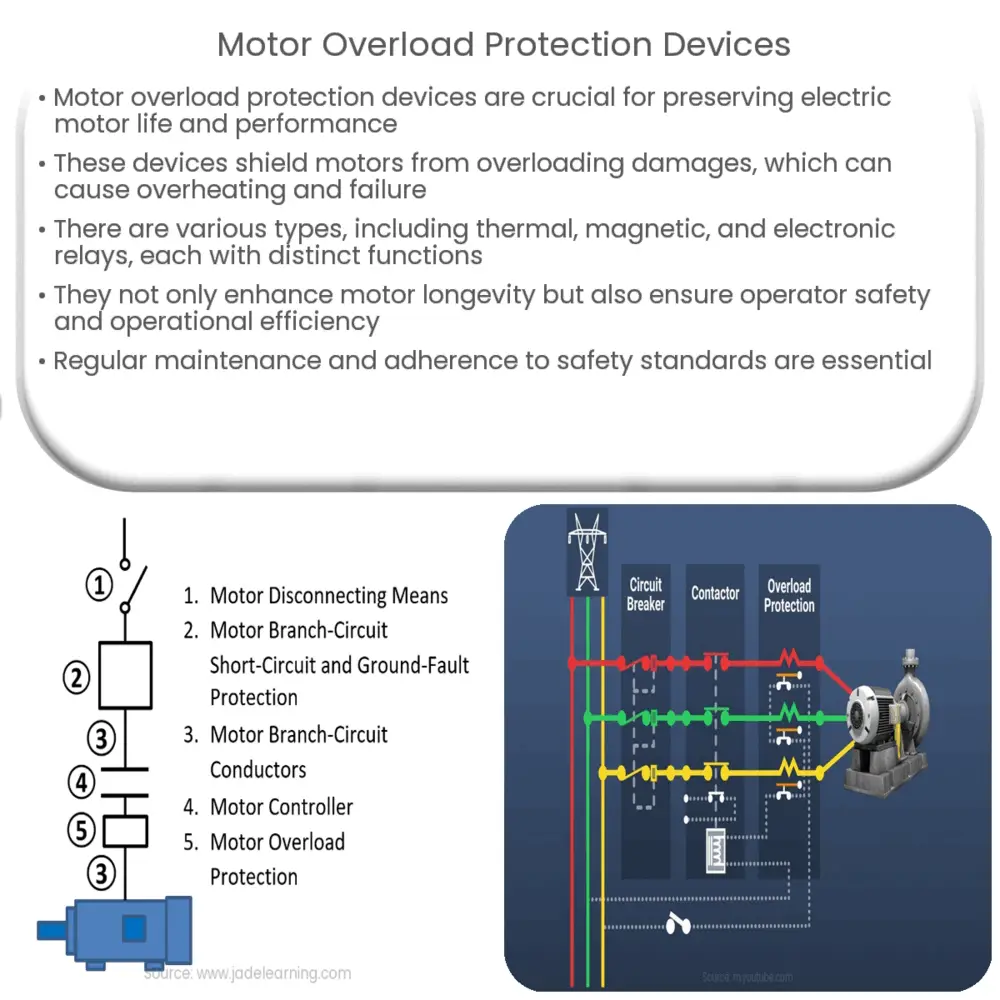

Motor overload protection devices play a crucial role in preserving the life and performance of electric motors. These safeguards protect motors from damage caused by overloading, which occurs when a motor runs beyond its design limit, potentially leading to overheating and eventual failure.

Types of Motor Overload Protection Devices

There are several types of motor overload protection devices, each with its unique capabilities and applications.

- Thermal Overload Relays: These devices are designed to provide reliable overload protection by utilizing a bimetallic strip that bends when heated by the electric current. When an overload occurs, the heat produced causes the strip to bend, which triggers the relay and breaks the circuit.

- Magnetic Overload Relays: A magnetic overload relay operates using an electromagnetic coil. Under normal load conditions, the coil is de-energized. But when the current exceeds the safe level, the coil energizes and moves the contact away from the power source, thus disconnecting the circuit.

- Electronic Overload Relays: These devices use microprocessors to monitor the motor’s current or heat and disconnect the power when an overload is detected. They offer adjustable settings, making them a flexible and precise option for motor protection.

Significance of Motor Overload Protection Devices

Motor overload protection devices contribute significantly to the longevity and efficient operation of motors. They prevent unnecessary damage due to overheating, thereby reducing the need for frequent repairs or replacements, which can be expensive and time-consuming.

Furthermore, these devices help ensure the safety of the operating personnel by preventing incidents caused by motor failure, such as fires or equipment damage.

The Functioning of Motor Overload Protection Devices

Motor overload protection devices work by monitoring the current flowing through the motor. When this current exceeds a pre-set level—indicating an overload—the device will trip the circuit, thus interrupting the power supply to the motor. This action effectively cools down the motor, preventing it from overheating and suffering damage.

The exact functioning of these devices varies depending on their type. However, they all share the fundamental objective of protecting motors from overloads and the associated consequences.

Choosing the Right Motor Overload Protection Device

When selecting an overload protection device, several factors need to be considered, such as the type and size of the motor, the motor’s application, and environmental conditions.

- Type and Size of the Motor: Different motor types and sizes require different protection devices. For example, large motors often use electronic overload relays due to their high accuracy and adjustable settings.

- Motor Application: The motor’s use case also affects the choice of overload protection. For instance, motors used in heavy-duty applications may require more robust overload protection than those used in light-duty tasks.

- Environmental Conditions: Factors such as ambient temperature and humidity can influence the performance of certain overload protection devices. Therefore, these conditions must be considered when choosing the appropriate device.

Maintenance of Motor Overload Protection Devices

Regular maintenance of these devices is essential to ensure their effective functioning. This typically involves periodic testing to ensure the device trips at the correct current level, along with visual inspection for signs of damage or wear.

Legal and Safety Standards

Motor overload protection is not just a matter of practicality and economics, but also of legal compliance. Several safety standards and regulations stipulate the use of overload protection devices for motors. These standards, such as those set by the National Electrical Code (NEC) in the United States, aim to protect both the equipment and the personnel operating it.

Conclusion

In conclusion, motor overload protection devices play an indispensable role in maintaining the integrity of electric motors, protecting them from damage due to overloads, and enhancing their lifespan. They also contribute to the safety of personnel and the overall efficiency of industrial operations. With different types of protection devices available, it’s crucial to select the appropriate device based on the motor type, size, application, and environmental conditions. Furthermore, regular maintenance and adherence to safety standards ensure the reliable and effective functioning of these devices.