Explore the importance of Motor Electromagnetic Interference (EMI) Filters, their role in reducing EMI, and tips for optimal use.

Understanding Motor Electromagnetic Interference (EMI) Filters

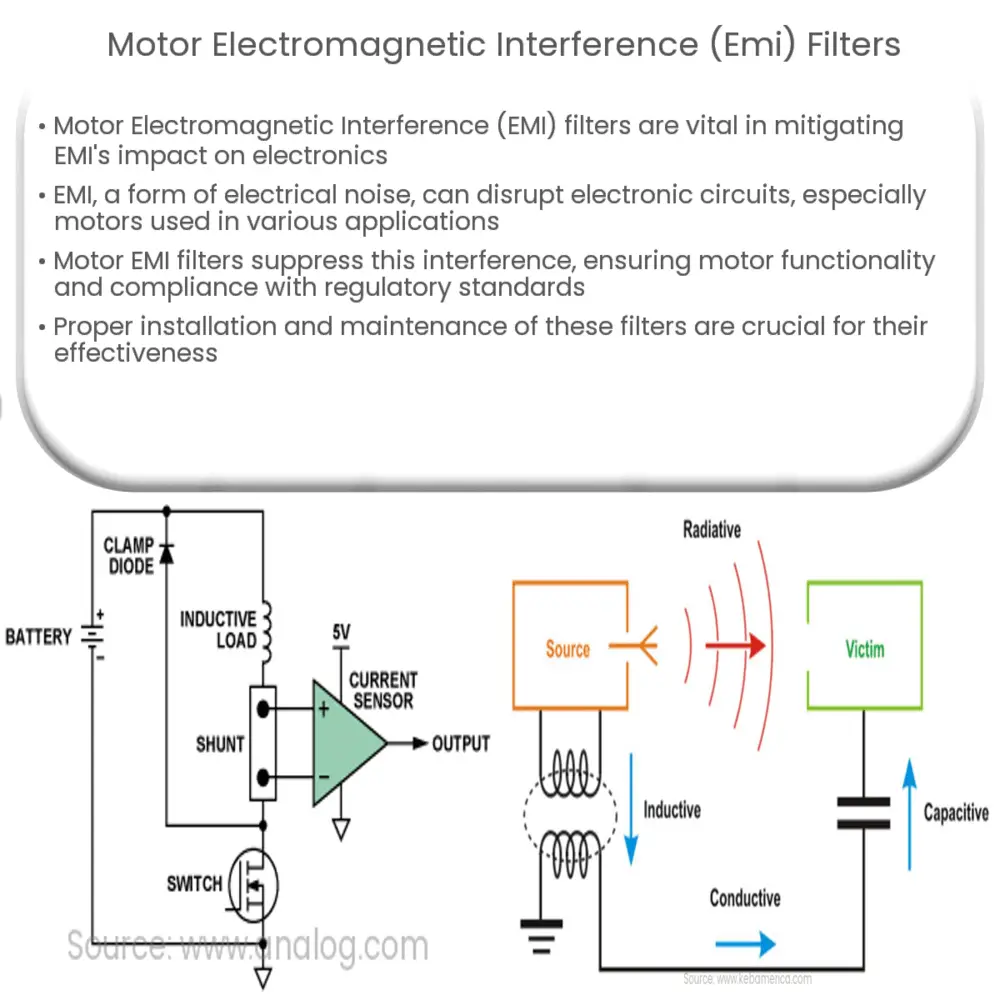

Motor Electromagnetic Interference (EMI) filters are an essential component in the realm of electronics and communications. They play a critical role in mitigating the impact of EMI, a form of electrical noise that can interfere with the functioning of electronic devices.

What is Electromagnetic Interference?

Electromagnetic Interference, also known as radio-frequency interference when in the radio frequency spectrum, is a disturbance that affects an electrical circuit due to either electromagnetic conduction or electromagnetic radiation emitted from an external source.

The interference can disrupt, degrade or even stop the proper functioning of an electronic circuit. This can be particularly problematic in the case of motors, which are fundamental to many industrial, commercial, and household applications.

The Role of Motor EMI Filters

The purpose of Motor EMI filters is to reduce the level of EMI/RFI (Radio Frequency Interference) in a system. They function by ‘filtering out’ the interference, preventing it from affecting the performance of the motor and other connected devices.

These filters are typically composed of components such as capacitors and inductors, which work together to suppress any high-frequency interference. By doing this, they ensure that the motor can function as intended without being disrupted by unwanted electrical noise.

Significance of Motor EMI Filters

EMI filters are a crucial element for ensuring the reliability and longevity of motors. Unfiltered EMI can lead to premature motor wear, increased maintenance requirements, and a higher risk of motor failure. It can also impact the performance of other electronic devices that are connected to the same power source.

Additionally, EMI has the potential to violate regulatory standards, leading to potential legal issues. Compliance with electromagnetic compatibility (EMC) standards is required in many regions, including the European Union, making the use of EMI filters a practical necessity.

Different Types of EMI Filters

-

Single-Phase Filters: These are used in applications where there is one live wire (phase) and one neutral wire.

-

Three-Phase Filters: These are designed for systems where three live wires (phases) are present.

How do EMI Filters Work?

EMI filters work by providing a low impedance path for the interference, effectively diverting it away from the electrical equipment. The filter is designed to have a high impedance to the operational frequency of the equipment but a low impedance to the frequencies of the interference. This allows the motor to operate normally while the interference is safely ‘filtered out’.

Choosing the Right EMI Filter

Choosing the right EMI filter for a motor involves considering a variety of factors. First, the type of motor and its operational environment need to be taken into account, as different motors will generate and be susceptible to different levels of EMI.

Other considerations include the filter’s insertion loss, which is a measure of its effectiveness, as well as its rated voltage and current. Always remember to consider the safety standards and certifications, especially if the motor is to be used in a commercial or industrial setting.

Installation and Maintenance

Proper installation of an EMI filter is crucial to its effectiveness. Filters should be installed as close as possible to the motor and ideally, the filter and motor should share a common grounding point. Additionally, it’s important to periodically check and maintain your EMI filters to ensure they continue to function effectively and safely.

The Future of Motor EMI Filters

With the increasing use of electronics and motors in a variety of applications, the importance of effective EMI filtering is only set to grow. Advances in technology are likely to lead to the development of more efficient and effective filters, helping to ensure that motors can continue to function reliably and effectively in an increasingly interconnected world.

Conclusion

In conclusion, Motor Electromagnetic Interference (EMI) filters are indispensable components in any system involving motors. They protect not only the motors themselves, but also other electronics that share the same power source, from the potential disruptions and damage caused by EMI. By understanding the fundamentals of EMI and the role of these filters, individuals and businesses can better protect their valuable equipment and ensure their systems operate at peak efficiency.