Explore the vital role of motor brushes in electric motors, their types, selection criteria, maintenance, and sustainable alternatives.

Introduction to Motor Brushes

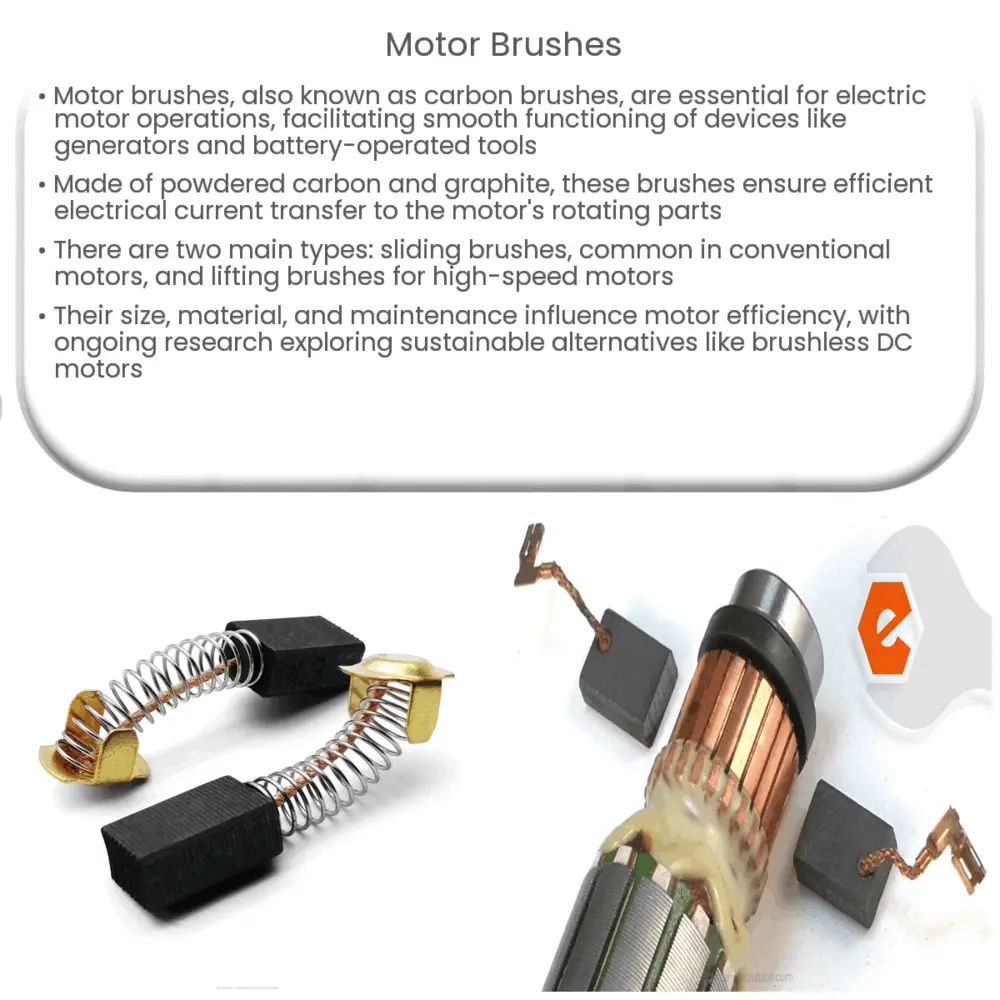

Motor brushes, commonly known as carbon brushes, are integral components of any electric motor. They play a vital role in ensuring the smooth operation of motors and devices such as generators, alternators, and battery-operated tools. Without these brushes, electric motors would not be able to function effectively.

Design and Functionality

Motor brushes are typically made from a mixture of powdered carbon and graphite, shaped and compacted into a solid block. This carbon block is attached to a metal spring or shunt which ensures constant pressure against the commutator or the slip ring in the motor.

-

Motor brushes serve as a crucial connection between the moving and stationary parts of the motor.

-

They ensure that electrical current is efficiently transferred to the rotating part of the motor, commonly referred to as the rotor or the armature.

-

Another important role of motor brushes is to help distribute current evenly across the segments of the rotor, aiding in smooth and continuous rotation.

Types of Motor Brushes

There are primarily two types of motor brushes:

-

The sliding brush, used in most conventional motors. It’s characterized by its design to slide or roll along the commutator, maintaining consistent electrical contact.

-

The lifting brush. In contrast to sliding brushes, lifting brushes are engineered to lift off the commutator at higher speeds to reduce friction and wear. They are commonly found in high-speed motors.

Wear and Tear

Like most components, motor brushes also undergo wear and tear. Due to the constant physical contact with the commutator or slip ring, the brushes gradually wear down. However, they’re designed for easy replacement to ensure continued performance of the motor.

The Impact of Brush Size and Material

The size and material of the brush play a significant role in motor efficiency. Smaller brushes tend to create more friction, leading to higher wear and tear. Similarly, the material of the brush can greatly influence its conductivity and durability. For instance, brushes with a higher percentage of graphite have a longer lifespan but tend to provide lesser conductivity, while those with a higher percentage of copper provide higher conductivity but wear out faster.

Choosing the Right Motor Brush

The choice of motor brush largely depends on the specific application, the type of motor in use, and the operating conditions. The speed of the motor, the current load, temperature, and environmental factors can all significantly impact the performance of the brush. Therefore, it’s vital to select the right brush that fits your needs.

-

If a motor is designed for high-speed operations, a lifting brush might be more suitable as it reduces friction at higher speeds.

-

For a motor operating under high temperature or load conditions, a brush with a higher percentage of graphite may be preferred for its increased durability.

-

In contrast, for motors requiring high conductivity, a brush with a higher percentage of copper may be more suitable.

Maintenance of Motor Brushes

Maintenance is a critical aspect of ensuring the long life and optimum performance of motor brushes. Regularly checking the brushes for wear and tear, monitoring motor performance, and replacing the brushes as needed can greatly extend the lifespan of a motor. Furthermore, the commutator or slip ring should also be kept clean and free of debris to avoid damaging the brushes and ensure efficient electrical transfer.

Environmentally Friendly Alternatives

As we continue to advance in technology and become more conscious of our environmental impact, efforts are being made to develop more sustainable alternatives to traditional carbon brushes. Some companies are exploring options such as brushless DC motors and solid-state brushes which promise longer lifespan, lower maintenance needs, and less environmental impact.

Conclusion

In conclusion, motor brushes play a vital role in the operation of electric motors, making them an indispensable component of our modern mechanical world. From their design and functionality to the materials used, each aspect of the brush impacts the efficiency of a motor. Understanding the basics of motor brushes, their types, and the factors that influence their performance can guide in the selection of the right brush for a specific motor or application. Furthermore, staying abreast with technological advancements can help us transition towards more sustainable and efficient alternatives in the future.