MEMS-based current sensors offer miniaturization, low power consumption, high sensitivity, and wide bandwidth, ideal for energy management, automotive, and consumer electronics applications.

MEMS-based Current Sensors: The Future of Sensing Technology

Introduction

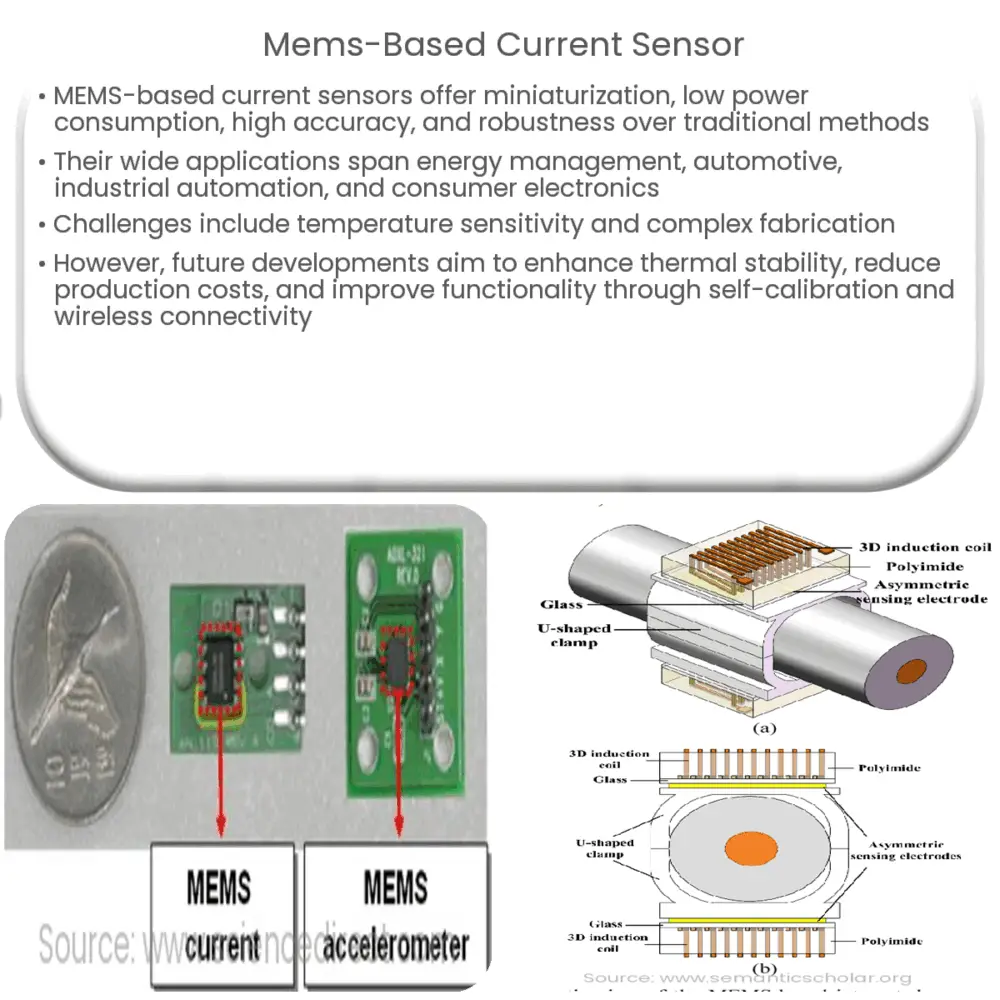

Microelectromechanical systems (MEMS) have gained significant traction in recent years as they combine the benefits of miniaturization, affordability, and enhanced functionality. In the realm of current sensing, MEMS-based sensors offer a promising alternative to traditional sensing technologies. This article delves into the principles, advantages, and applications of MEMS-based current sensors.

Principles of MEMS-based Current Sensors

MEMS-based current sensors rely on the principle of magnetoresistive sensing, where changes in the magnetic field caused by the flow of current are measured. The sensors are fabricated using microfabrication techniques that create miniature components on a semiconductor substrate. The design of MEMS-based current sensors typically includes a magnetoresistive material, such as permalloy or spintronic materials, which exhibit a change in resistance when exposed to a magnetic field. These changes can be detected and processed by integrated electronic circuits, providing a digital output that is proportional to the current being measured.

Advantages of MEMS-based Current Sensors

MEMS-based current sensors offer several advantages over traditional sensing technologies, such as Hall-effect sensors or Rogowski coils:

- Miniaturization: Due to the microfabrication process, MEMS-based current sensors are significantly smaller than their traditional counterparts. This allows for easier integration into compact systems and devices.

- Low Power Consumption: MEMS-based current sensors typically consume less power than Hall-effect sensors, making them ideal for battery-powered applications or other power-sensitive scenarios.

- High Sensitivity and Accuracy: The magnetoresistive materials used in MEMS-based current sensors can detect minute changes in magnetic fields, resulting in high sensitivity and accuracy over a wide range of current values.

- Wide Bandwidth: MEMS-based current sensors have a wider bandwidth compared to traditional sensors, enabling them to measure fast-changing currents and work effectively in high-frequency applications.

- Robustness: MEMS-based current sensors exhibit a high degree of immunity to external electromagnetic interference (EMI), making them suitable for use in electrically noisy environments.

Applications of MEMS-based Current Sensors

With their unique advantages, MEMS-based current sensors find applications in a variety of industries and domains:

- Energy Management: Smart grids and energy-efficient systems rely on accurate current measurement for monitoring and controlling energy consumption. MEMS-based current sensors enable precise real-time monitoring of energy usage, facilitating better load management and efficiency improvements.

- Automotive: In electric vehicles, MEMS-based current sensors can be used for monitoring battery charge and discharge rates, ensuring optimal performance and battery health.

- Industrial Automation: The precision and robustness of MEMS-based current sensors make them well-suited for industrial applications, where accurate current measurement is critical for process control and equipment protection.

- Consumer Electronics: MEMS-based current sensors can be integrated into portable devices, such as smartphones and wearables, for monitoring power consumption and battery management.

Challenges and Future Developments

Despite their numerous advantages, MEMS-based current sensors face some challenges that must be addressed for wider adoption:

- Thermal Stability: The performance of magnetoresistive materials may be affected by temperature fluctuations, leading to reduced accuracy or sensitivity. Research is underway to develop materials and designs that exhibit improved thermal stability.

- Manufacturing Complexity: The fabrication process of MEMS-based current sensors can be complex and expensive, particularly when incorporating magnetoresistive materials. Advances in manufacturing techniques and the development of more cost-effective materials will help lower production costs and increase accessibility.

Future developments in MEMS-based current sensing technology are expected to address these challenges and expand the capabilities of these sensors. Some potential areas of advancement include:

- Self-Calibration: Self-calibrating MEMS-based current sensors could automatically adjust for temperature variations or drift, maintaining accuracy and stability over time.

- Integrated Systems: The integration of MEMS-based current sensors with other sensing elements, such as voltage or temperature sensors, will enable more comprehensive monitoring and control capabilities in various applications.

- Wireless Connectivity: Incorporating wireless communication capabilities into MEMS-based current sensors will facilitate easier data collection and remote monitoring, making them more versatile and user-friendly.

Conclusion

MEMS-based current sensors represent a significant advancement in sensing technology, offering a range of benefits over traditional sensing methods. Their miniaturized design, low power consumption, high sensitivity, wide bandwidth, and robustness make them ideal for a variety of applications in industries such as energy management, automotive, industrial automation, and consumer electronics. As research continues and manufacturing techniques improve, MEMS-based current sensors will likely become an increasingly important component in the world of sensing technology, enabling more accurate and efficient monitoring and control of electrical currents.