Magnetostrictive actuators use magnetic fields to alter ferromagnetic materials, enabling precise motion control across various industries.

Magnetostrictive Actuator: Principles, Applications, and Future Prospects

Part 1: Introduction to Magnetostrictive Actuators

Magnetostrictive actuators have emerged as a promising technology in the field of precision motion control and actuation. These actuators exploit the magnetostrictive effect, a phenomenon in which certain ferromagnetic materials change shape when subjected to a magnetic field. The resulting motion can be harnessed for a wide variety of applications, from aerospace to biomedical engineering.

Principles of Magnetostriction

Magnetostriction occurs in certain ferromagnetic materials due to the interaction between their atomic magnetic moments and the external magnetic field. When a magnetic field is applied, the material’s atomic magnetic moments align with the field, causing a change in the material’s dimensions. This change is known as the magnetostrictive strain, and it can be either positive (elongation) or negative (contraction).

The most commonly used magnetostrictive materials include Terfenol-D, Metglas, and Galfenol. Terfenol-D, an alloy of terbium, dysprosium, and iron, exhibits the largest magnetostrictive strain among commercially available materials. Galfenol, an iron-gallium alloy, offers excellent mechanical robustness, while Metglas, a metallic glass, is known for its rapid response to magnetic fields.

Magnetostrictive Actuator Design

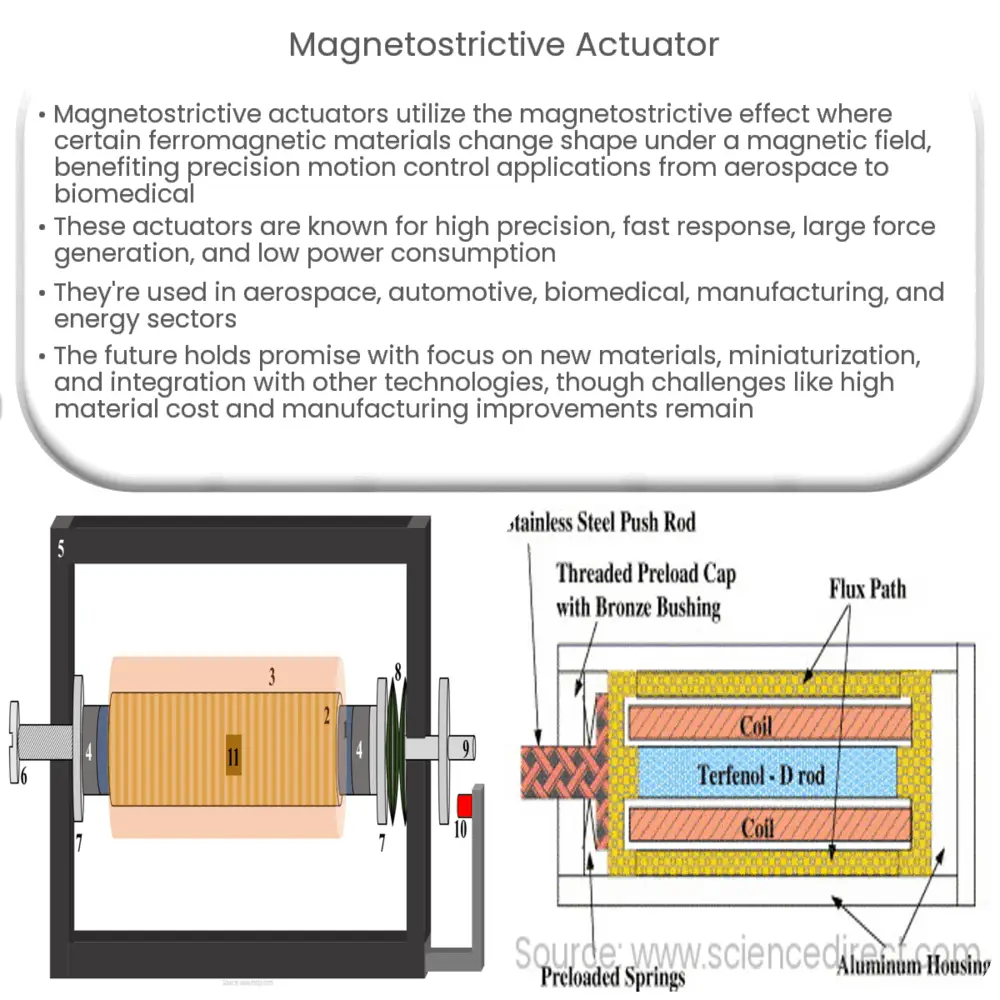

A typical magnetostrictive actuator comprises three main components: the magnetostrictive material, a coil, and a mechanical assembly for transmitting motion. The coil generates a magnetic field when current flows through it, causing the magnetostrictive material to change shape. The mechanical assembly then transforms this shape change into useful motion, such as linear or rotary motion.

Magnetostrictive actuators can be designed in various configurations, depending on the specific application requirements. For example, a linear magnetostrictive actuator may use a rod-shaped magnetostrictive material, while a rotary actuator may incorporate a ring-shaped material. Additionally, the actuator’s performance can be tuned by adjusting factors such as the coil’s geometry, the magnetostrictive material’s dimensions, and the mechanical assembly’s design.

Advantages of Magnetostrictive Actuators

Magnetostrictive actuators offer several advantages over other types of actuators, such as piezoelectric and electrostrictive actuators. Key benefits include:

- High precision: Magnetostrictive actuators can achieve sub-micrometer positioning accuracy, making them suitable for applications that demand precise motion control.

- Fast response: These actuators can respond to changes in the magnetic field in microseconds, enabling high-speed operation.

- Large force generation: Magnetostrictive actuators can produce substantial forces, even at small displacements, making them well-suited for applications that require high force output.

- Low power consumption: Due to their energy-efficient operation, magnetostrictive actuators can help minimize power consumption in various applications.

Part 2: Applications of Magnetostrictive Actuators

Magnetostrictive actuators find applications in a diverse range of industries, thanks to their unique combination of precision, speed, and force generation capabilities. Some notable applications include:

- Aerospace: In the aerospace industry, magnetostrictive actuators are used for active vibration control, adaptive wing shaping, and precision positioning of satellite antennas and mirrors.

- Automotive: These actuators can be found in automotive applications such as active suspension systems, valve control in engines, and noise cancellation in vehicle cabins.

- Biomedical: Magnetostrictive actuators are employed in drug delivery systems, surgical instruments, and haptic feedback devices for medical training and rehabilitation.

- Manufacturing: In manufacturing, magnetostrictive actuators are used for precision assembly, machine tool positioning, and quality control testing, among other tasks.

- Energy: These actuators play a role in energy production and conversion, such as in the control of wind turbine blades, wave energy converters, and solar panel positioning.

Future Prospects and Challenges

The future of magnetostrictive actuator technology holds great promise, with research and development efforts focused on enhancing the performance and expanding the range of applications. Key areas of exploration include:

- New materials: The discovery and development of new magnetostrictive materials with improved properties, such as higher strain, better temperature stability, and reduced hysteresis, could significantly advance the capabilities of magnetostrictive actuators.

- Miniaturization: As demand grows for smaller and more efficient devices, there is a need to develop miniaturized magnetostrictive actuators that can deliver high performance in compact form factors.

- Integration with other technologies: Combining magnetostrictive actuators with other actuation technologies, such as piezoelectric or electrostatic, could enable the development of hybrid systems with enhanced performance and functionality.

Despite the potential for growth and innovation, there are challenges that must be addressed to realize the full potential of magnetostrictive actuator technology. Some of these challenges include the high cost of certain magnetostrictive materials, the need for improved manufacturing processes, and the development of reliable and robust control systems. As researchers and engineers continue to push the boundaries of magnetostriction, it is likely that we will see even more exciting advancements and applications in the years to come.

Conclusion

Magnetostrictive actuators offer a unique blend of high precision, rapid response, and large force generation, making them an increasingly attractive option for a wide range of applications. As research progresses and new materials and technologies are developed, the future of magnetostrictive actuators promises to be even more exciting and transformative for industries worldwide.