Explore magnetoresistive sensors, their working principles, types, applications, and future prospects in this comprehensive guide.

Magnetoresistive Sensors: A Comprehensive Understanding

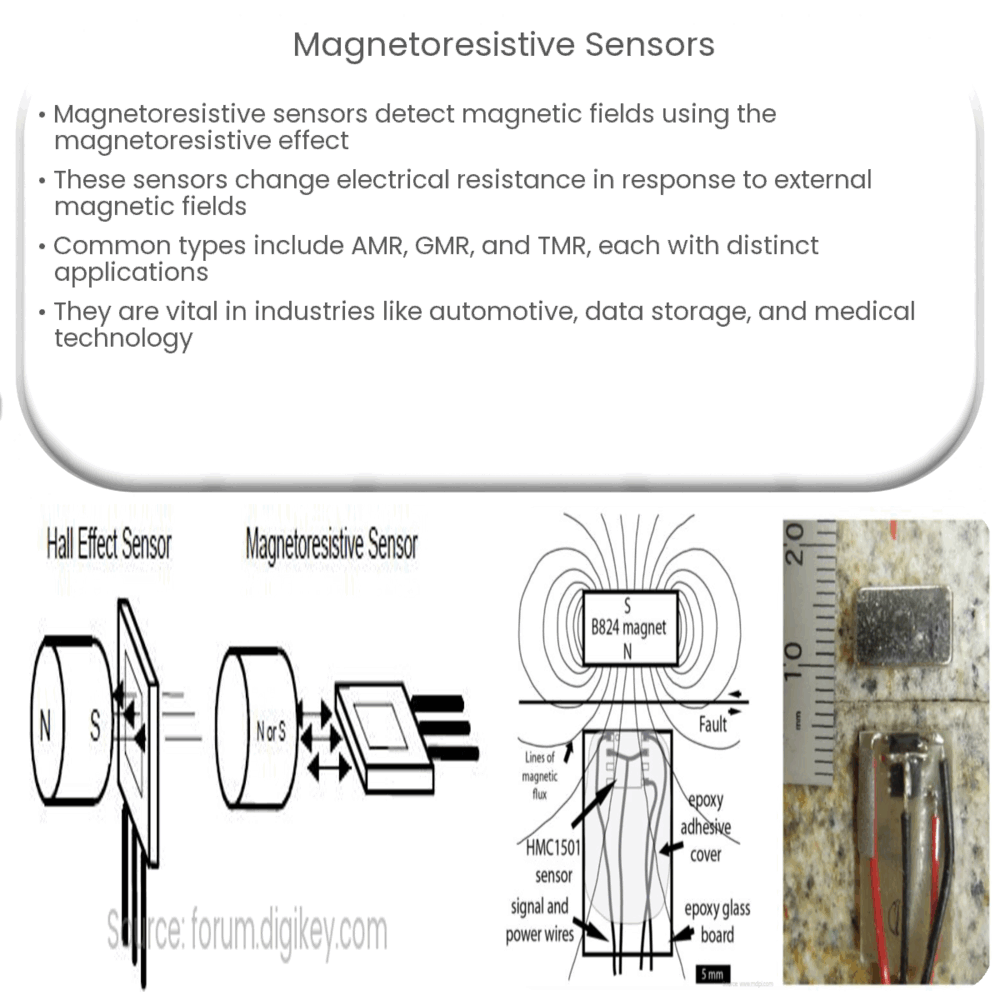

Magnetoresistive sensors are a type of sensor that utilize the magnetoresistive effect to detect magnetic fields. This technology has a wide range of applications from consumer electronics to industrial processes and even space exploration.

Understanding the Magnetoresistive Effect

The magnetoresistive effect, the principle behind these sensors, is a property exhibited by certain materials where their electrical resistance changes in response to an external magnetic field. This phenomenon was first observed in the mid-19th century, and the development of magnetoresistive sensors has since evolved, harnessing this effect for practical applications.

Types of Magnetoresistive Sensors

-

Anisotropic Magnetoresistive (AMR) Sensors

The most common type of magnetoresistive sensor, AMR sensors, change their resistance based on the angle of an applied magnetic field. They are often used in applications that require precise positioning and direction detection.

-

Giant Magnetoresistive (GMR) Sensors

As the name suggests, GMR sensors exhibit a larger magnetoresistive effect than AMR sensors. They are composed of alternating thin layers of magnetic and non-magnetic materials. Their high sensitivity makes them suitable for reading data in hard disk drives.

-

Tunnel Magnetoresistive (TMR) Sensors

TMR sensors leverage the quantum mechanical effect of tunneling. They are formed by sandwiching a thin insulating layer between two magnetic layers. The resistance change in TMR sensors is significantly higher than in AMR and GMR sensors, making them effective for applications requiring high sensitivity.

Working Principle

The working principle of magnetoresistive sensors involves the change in resistance of a magnetoresistive material when exposed to a magnetic field. In the absence of a magnetic field, the electrical resistance of the material remains constant. When a magnetic field is applied, the resistance changes in proportion to the strength and direction of the field. This change can be measured and converted into an electrical signal, which is then interpreted by a microcontroller or other electronic device.

Applications of Magnetoresistive Sensors

Magnetoresistive sensors have a myriad of applications in various industries due to their high sensitivity and accuracy. Here are some key areas where they are commonly used:

-

Automotive Industry: These sensors are used for detecting wheel speed, steering angle, and transmission gear speed, among other applications. They are crucial in the functioning of Anti-lock Braking Systems (ABS) and Electronic Stability Control (ESC) systems.

-

Data Storage: In hard disk drives, GMR sensors are used to read data. The high sensitivity of GMR sensors allows for increased data storage density, making them an essential component in modern computing.

-

Industrial Automation: Magnetoresistive sensors are used for non-contact position sensing in automated systems, contributing to increased efficiency and safety.

-

Medical Technology: In medical devices, these sensors help in precise measurement and control. For example, they are used in Magnetic Resonance Imaging (MRI) machines to measure the magnetic fields.

Future of Magnetoresistive Sensors

The future of magnetoresistive sensors looks promising with ongoing advancements in nanotechnology and materials science. With the potential for higher sensitivity and smaller form factors, these sensors may soon find their way into more applications, including wearable technology, advanced robotics, and even more precise medical devices. As the world continues to digitize, the demand for these sensors will likely increase, making them an integral part of our technological future.

Conclusion

In conclusion, magnetoresistive sensors, capitalizing on the magnetoresistive effect, play a pivotal role in a wide array of applications. The diverse types of these sensors, including AMR, GMR, and TMR, each have unique attributes that make them suitable for specific uses, ranging from automotive systems to data storage and industrial automation. As advancements continue in this field, we can expect these versatile devices to further revolutionize the technological landscape. The future beckons with the promise of even more sophisticated magnetoresistive sensors, primed to drive innovation across industries.