Magnetic planetary gears use embedded magnets for torque transmission, offering reduced wear, increased efficiency, and smooth, quiet operation.

Magnetic Planetary Gear: Revolutionizing Mechanical Systems

Introduction

The world of mechanical engineering is constantly evolving, with new technologies and materials emerging to improve the efficiency and functionality of systems. One recent development that has garnered significant attention is the magnetic planetary gear, a novel solution with the potential to revolutionize various industries. This article delves into the concept, workings, and potential applications of magnetic planetary gears, highlighting their advantages over traditional systems.

Understanding Magnetic Planetary Gears

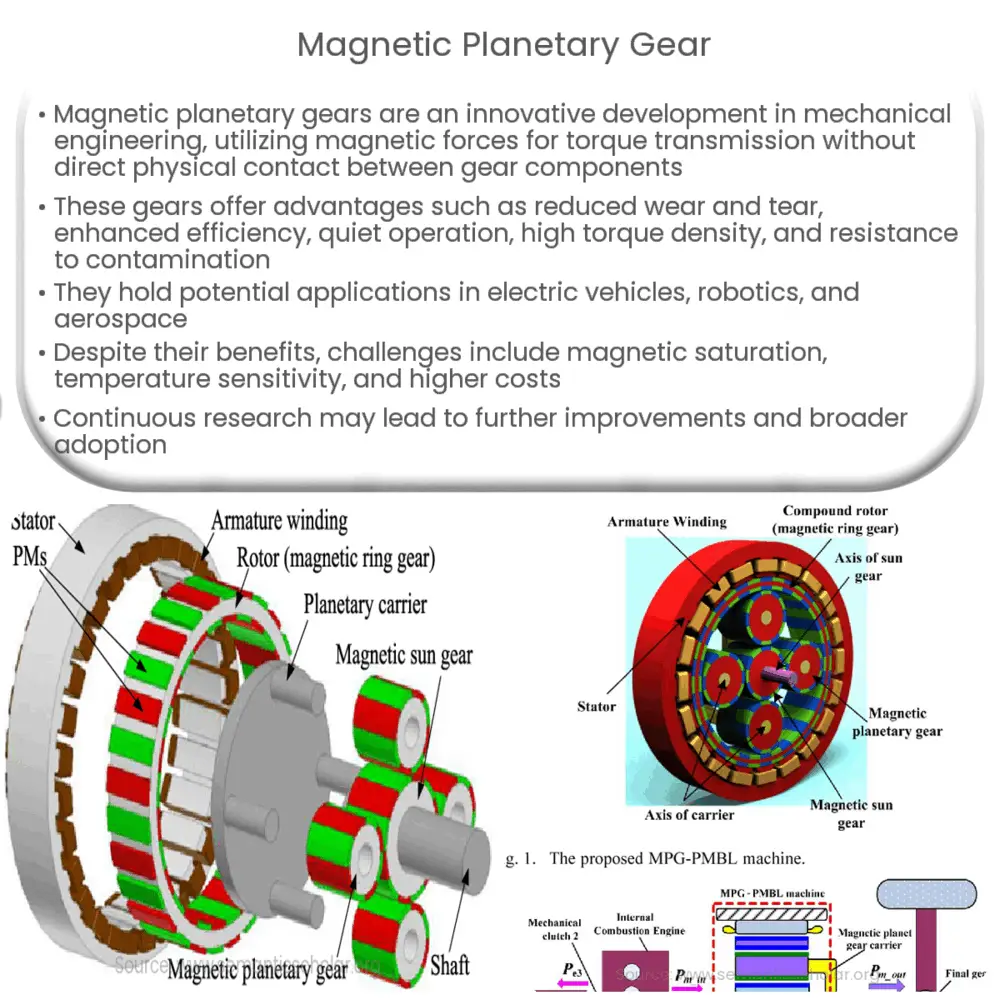

A magnetic planetary gear system, at its core, consists of a central sun gear, multiple planet gears, and an external ring gear. The gears are held together not by direct physical contact, but by magnetic forces. These magnetic forces are generated by embedding permanent magnets in each gear component, which interact with one another to create torque transmission. The combination of these magnetic interactions and precise gear alignments allows for efficient power transmission without physical contact between components.

Advantages of Magnetic Planetary Gears

The implementation of magnetic forces in planetary gear systems offers a range of advantages over their traditional counterparts. Key benefits include:

- Reduced wear and tear: The absence of physical contact between gears reduces friction, minimizing wear and tear on the system. This leads to longer operational life and reduced maintenance costs.

- Increased efficiency: Lower friction also results in less energy loss during operation, making magnetic planetary gears more energy-efficient than traditional systems.

- Smooth and quiet operation: The lack of mechanical contact between components results in a smoother, quieter operation, making these systems suitable for applications where noise reduction is crucial.

- High torque density: The magnetic forces enable high torque transmission, allowing for compact designs with a high power-to-weight ratio.

- Resistance to contamination: The absence of physical contact means that the system is less susceptible to contamination by dust, debris, or other foreign materials, improving its reliability in harsh environments.

Potential Applications

Magnetic planetary gears have the potential to disrupt a wide range of industries due to their unique advantages. Some possible applications include:

- Electric vehicles: The high efficiency and low noise characteristics of magnetic planetary gears make them an attractive option for electric vehicle transmissions, potentially improving performance and reducing energy consumption.

- Robotics: The compact design and high torque density offered by these systems can enhance the performance of robotic systems, particularly in applications where space and weight constraints are crucial.

- Aerospace: The reduced wear and tear and resistance to contamination make magnetic planetary gears suitable for use in aerospace applications, where reliability and longevity are essential.

Challenges and Limitations

While magnetic planetary gears offer numerous advantages, they also face some challenges and limitations:

- Magnetic saturation: The effectiveness of magnetic forces is limited by the saturation of the permanent magnets used. If the demand for torque transmission exceeds the magnetic force capacity, the system’s performance may suffer.

- Temperature sensitivity: Magnetic properties can be affected by temperature changes, potentially impacting the performance of the gear system. Designers must account for temperature fluctuations in their applications to ensure consistent operation.

- Cost: The manufacturing and assembly of magnetic planetary gears may be more expensive than traditional gear systems due to the need for specialized magnets and precise alignment. This could limit the widespread adoption of this technology, especially in cost-sensitive applications.

Future Developments

As with any emerging technology, ongoing research and development will likely lead to improvements in the design and performance of magnetic planetary gears. Future advancements may include:

- New magnetic materials: The development of advanced magnetic materials with higher energy densities and temperature stability could enhance the performance and capabilities of magnetic planetary gear systems.

- Optimization techniques: Improved computational methods for optimizing the magnetic force distribution and gear alignment in these systems may result in even greater efficiency and torque density.

- Integration with other technologies: Combining magnetic planetary gears with other innovative technologies, such as additive manufacturing or smart materials, could lead to the creation of entirely new mechanical systems with enhanced functionality and performance.

Conclusion

Magnetic planetary gears represent a promising step forward in mechanical engineering, offering a range of advantages over traditional gear systems. Their unique features, such as reduced wear and tear, increased efficiency, and smooth, quiet operation, make them well-suited to applications in electric vehicles, robotics, and aerospace. However, challenges related to magnetic saturation, temperature sensitivity, and cost must be addressed to fully realize their potential. Continued research and development in this area will likely yield further improvements, paving the way for more widespread adoption of this innovative technology in the future.