Explore the world of magnetic gears, their types, applications, advantages, and future potential in our comprehensive guide on this emerging technology.

Understanding Magnetic Gears

Magnetic gears, a rising star in the field of mechanical and electrical engineering, are an intriguing alternative to their traditional mechanical counterparts. Harnessing the power of magnetism, they promise a host of benefits, including reduced maintenance needs, increased efficiency, and a unique, non-contact mode of operation. This article delves into the underlying principles of magnetic gears, their types, and potential applications.

Principles of Magnetic Gears

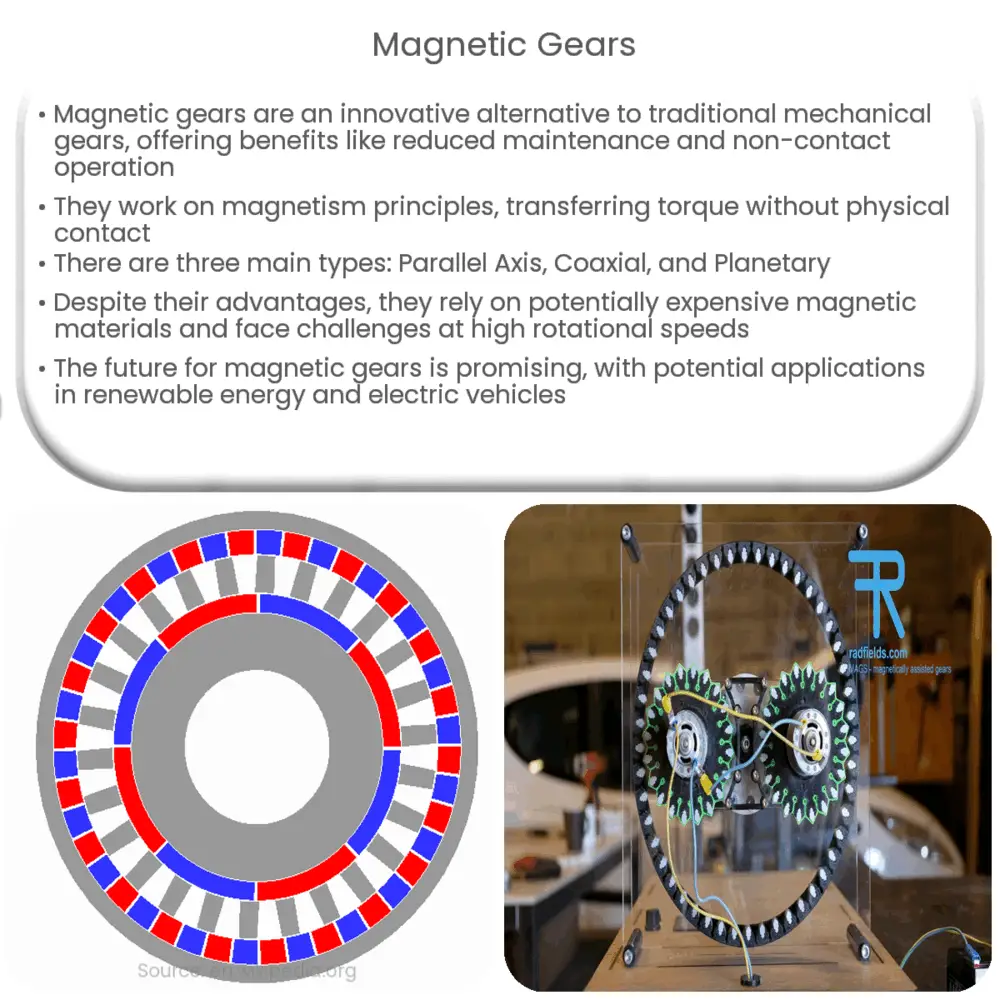

Magnetic gears operate based on the principles of magnetism. Unlike conventional gears, which rely on the physical contact of teeth to transmit torque, magnetic gears use magnetic fields. The gears consist of two concentric rotors, one with permanent magnets and the other with a set of ferromagnetic pole pieces. The magnetic fields generated by the permanent magnets interact with the pole pieces, causing them to rotate in sync, thus transferring torque without any physical contact.

Types of Magnetic Gears

- Parallel Axis Magnetic Gears: These gears feature two parallel axes where the input and output rotors are situated. The intermediary rotor, located between the input and output, contains alternating pole magnetic pieces which facilitate the transfer of torque.

- Coaxial Magnetic Gears: In these gears, the input and output shafts are aligned along the same axis. This design, coupled with the non-contact nature of the gears, allows for excellent torque density and high efficiency.

- Planetary Magnetic Gears: Planetary magnetic gears are designed with one or more rotating gear components (planet gears) that revolve around the central, or sun gear. This results in a compact design with high torque output and efficiency.

Applications of Magnetic Gears

Magnetic gears find applications in a broad spectrum of industries, thanks to their unique characteristics. Their non-contact operation minimizes wear and tear, thereby reducing maintenance costs and enhancing longevity. In environments where noise reduction is crucial, such as in healthcare or residential settings, magnetic gears’ virtually silent operation is highly beneficial. They also thrive in harsh conditions where traditional gears might fail, such as under extreme temperatures or corrosive conditions. In the energy sector, their high efficiency makes them ideal for use in renewable energy systems like wind turbines.

Advantages of Magnetic Gears

Magnetic gears offer several significant advantages over traditional mechanical gears. Firstly, their non-contact mode of operation results in virtually zero mechanical wear, significantly reducing maintenance needs. This leads to increased operational reliability and a longer lifespan. Secondly, magnetic gears are inherently overload-protected. In extreme conditions, they slip instead of breaking, thereby avoiding catastrophic mechanical failure. Additionally, their operation is virtually silent, an important factor in noise-sensitive environments.

Limitations of Magnetic Gears

Despite their numerous advantages, magnetic gears are not without limitations. One major drawback is their dependency on magnetic materials, which can be expensive and are subject to price volatility. Furthermore, at high rotational speeds, the performance of magnetic gears tends to decrease due to the magnetic field’s limitations. Also, their design and manufacturing processes are more complex than traditional gears, potentially increasing initial costs.

Future of Magnetic Gears

As the demand for more efficient, reliable, and eco-friendly technologies continues to grow, the future looks bright for magnetic gears. Their potential applications in renewable energy systems, electric vehicles, and various industrial settings are promising. Research and development in this field are rapidly advancing, focusing on improving performance at high speeds, reducing costs, and developing new designs and configurations. With these improvements, magnetic gears are poised to become a significant player in the future of power transmission systems.

Conclusion

In conclusion, magnetic gears represent an exciting advancement in the realm of mechanical and electrical engineering. Offering numerous benefits such as reduced maintenance needs, overload protection, and silent operation, they present a compelling alternative to traditional gears. Despite certain limitations, their potential applications in various industries make them a promising technology for the future. As we continue to develop and refine this technology, we can expect to see a broader adoption of magnetic gears in the years to come, revolutionizing the world of power transmission.