Explore the world of magnetic actuators, their working principles, applications in various industries, and recent advancements.

Introduction to Magnetic Actuators

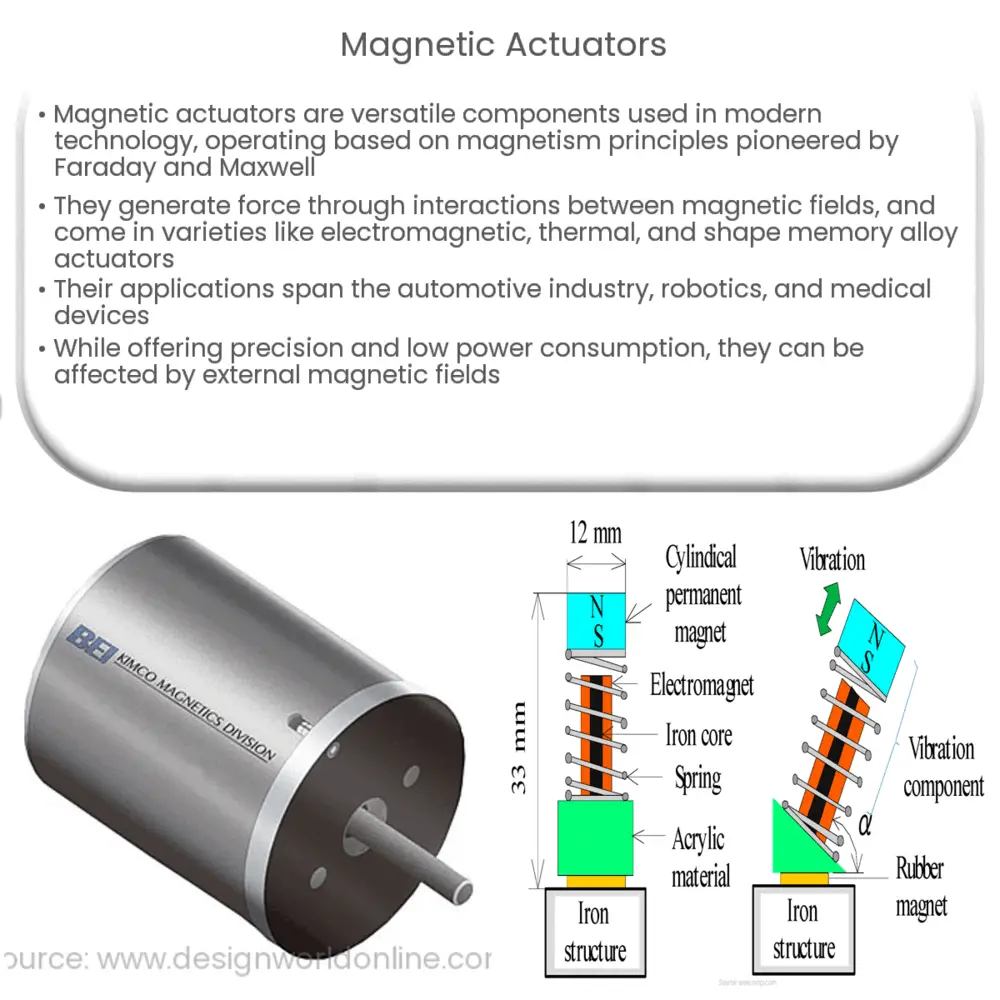

Magnetic actuators stand as one of the most versatile components in modern technology, utilized in a wide range of applications. The working principle behind these innovative devices is primarily based on the fundamental laws of magnetism and electromagnetic induction, established by pioneers like Michael Faraday and James Clerk Maxwell.

The Principle of Operation

The fundamental operation of a magnetic actuator relies on the magnetic field generated by an electrical current. When an electric current is passed through a coil in the actuator, it generates a magnetic field which interacts with the magnetic field of a permanent magnet or another coil. This interaction results in a force which can be used to move, or actuate, a mechanism.

- Electromagnetic Actuators: These are the most common type of magnetic actuator. Here, an electrical current is used to generate a magnetic field in a coil, which interacts with a permanent magnet or another coil to generate a force.

- Thermal Magnetic Actuators: These actuators work on a slightly different principle. In these, a magnetic material is heated to its Curie temperature, at which point its magnetic properties change, causing a shift in the magnetic field and thus generating a force.

- Shape Memory Alloy Actuators: These actuators use a magnetic shape memory alloy that changes shape when exposed to a magnetic field. This change in shape can be used to generate a force.

Applications of Magnetic Actuators

- Automotive Industry: Magnetic actuators are used in numerous applications in the automotive industry, including power windows and locking systems.

- Robotics: In robotics, magnetic actuators can be used to control the movement of robots, specifically in micro-robotics and nanorobotics where the precise control is necessary.

- Medical Devices: Certain medical devices also utilize magnetic actuators, such as in the precise control of surgical robots or drug delivery systems.

In the next part, we will delve deeper into the intricacies of these applications, explore the advantages and potential drawbacks of magnetic actuators, and touch upon some recent advancements in this field.

Detailed Applications of Magnetic Actuators

As previously mentioned, the applications of magnetic actuators are vast and varied. Let’s take a closer look at some specific use cases:

Automotive Industry

In the automotive industry, actuators are often used in a vehicle’s power windows and central locking system. The magnetic actuator works by converting the electrical energy from the car’s power system into the mechanical energy required to raise or lower the window or lock the doors. This not only enhances the convenience but also increases the safety aspect of vehicles.

Robotics

In the field of robotics, especially micro-robotics and nanorobotics, precision is of paramount importance. Magnetic actuators provide this high level of accuracy, allowing for precise movements and control. For instance, they are employed in robotic arms used in manufacturing processes for accurate positioning and movement.

Medical Devices

Healthcare technology has also benefited greatly from the use of magnetic actuators. They are often used in advanced surgical robots, where precision is vital. These robots can carry out intricate procedures with a level of accuracy that far exceeds human capabilities. Similarly, drug delivery systems can use magnetic actuators to release precise amounts of medication, improving patient outcomes.

Advantages and Potential Drawbacks

Magnetic actuators offer several benefits, including high precision, low power consumption, and the ability to operate in harsh environments. However, they also have some potential drawbacks, such as potential interference from external magnetic fields and the need for a power source to generate the electric current.

Recent Advancements

Recent advancements in magnetic actuator technology include the development of miniaturized actuators for use in micro and nanorobotic applications. Additionally, researchers are exploring the use of novel materials, like graphene, to enhance the performance and efficiency of these devices.

Conclusion

In conclusion, magnetic actuators are vital components in various sectors, including automotive, robotics, and medical devices. Their operation, based on the principles of electromagnetism, allows for high precision and efficiency. Despite some potential drawbacks, ongoing research and technological advancements continue to expand their potential applications, solidifying their place in the future of technological development.