Explore the world of Linear Induction Motors (LIMs), their principles, applications, design considerations, and pros and cons in our detailed guide.

Understanding Linear Induction Motors

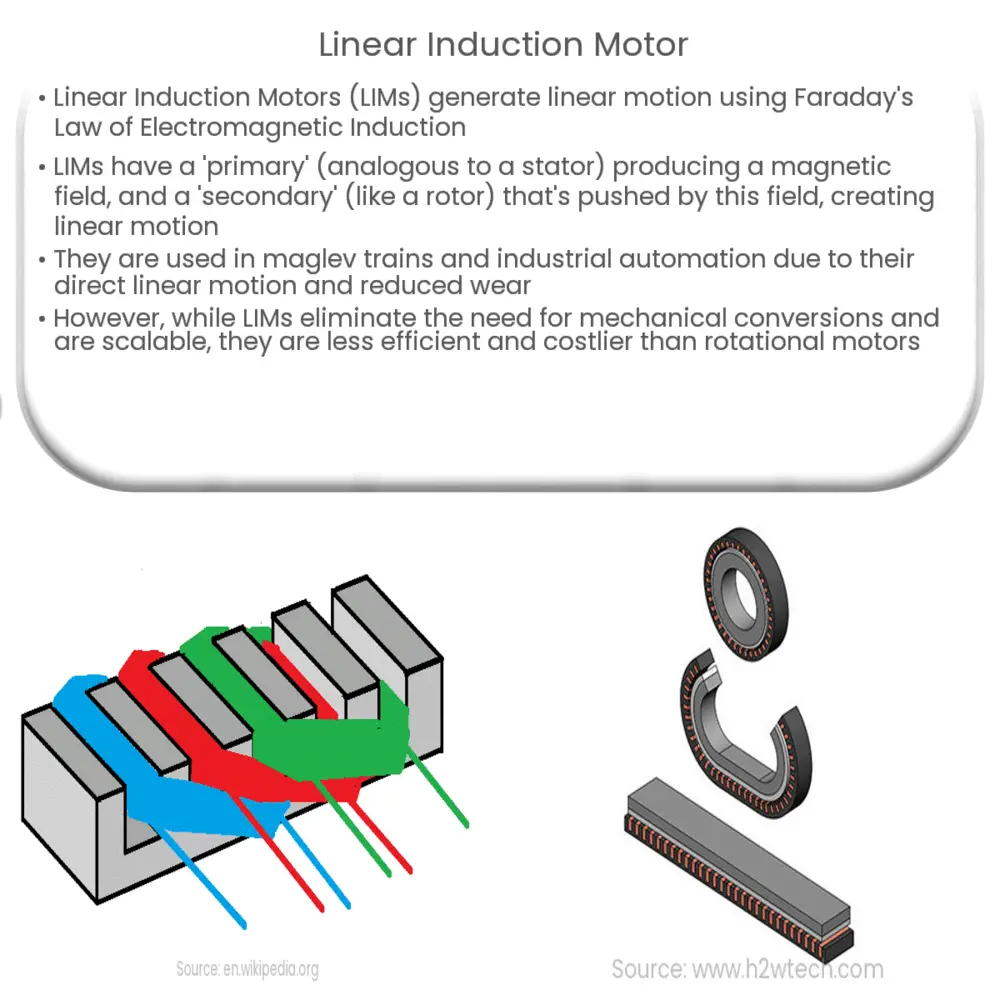

A Linear Induction Motor (LIM) is a special type of electric motor designed to generate linear motion rather than rotational motion, as seen in typical induction motors. This principle is based on Faraday’s Law of Electromagnetic Induction, which forms the cornerstone of all electric motor operations.

Principles and Construction

The fundamental operation of the LIM is hinged on the basic principles of electromagnetic induction. It operates on the same principles as a rotating induction motor but differs primarily in its physical construction. A typical LIM consists of a ‘primary’ which is equivalent to the stator in a conventional motor, and a ‘secondary’ which is analogous to the rotor.

- The Primary is made of laminated iron cores, with three-phase windings arranged in a specific pattern. When AC power is supplied, a travelling magnetic field is produced.

- The Secondary, usually a flat aluminium or copper plate, acts as a short-circuited single turn secondary winding. The travelling magnetic field induces currents in the secondary, creating an opposing magnetic field. According to Lenz’s law, the secondary is pushed away from the primary, creating linear motion.

Applications of Linear Induction Motors

Linear induction motors are utilized in various applications due to their unique characteristics. Their contactless operation reduces wear and tear, and the linear motion they produce can be directly used, eliminating the need for mechanical conversion systems.

- Transportation: LIMs are used in some modern train systems for propulsion. The motor is installed along the track, and the train carriage acts as the secondary. This system is known as magnetic levitation or maglev, and it allows for extremely high-speed, smooth, and quiet operation.

- Industrial Automation: In conveyor systems, LIMs provide smooth and continuous movement of goods, reducing mechanical complexity and maintenance requirements.

Theoretical Aspects and Mathematical Concepts

The theory and mathematics behind linear induction motors involve complex concepts from electromagnetism and electrical engineering. Key among these are Faraday’s Law, Lenz’s Law, and the Lorentz Force Law. These principles help us understand how a change in magnetic field can induce an electromotive force (EMF) and consequently, current in a conductor, and how this current can interact with the magnetic field to produce force.

Design Considerations and Performance Factors

Designing a Linear Induction Motor involves some key considerations to ensure optimal performance. These include the selection of the proper magnetic materials, designing the primary windings to achieve a well-distributed magnetic field, and choosing an appropriate secondary material and thickness. One of the most critical performance factors in a LIM is the ‘slip’, the difference between the speed of the primary’s magnetic field and the secondary’s actual speed.

Advantages and Disadvantages of Linear Induction Motors

Like all technologies, LIMs come with their unique set of advantages and disadvantages:

- Advantages: The most significant benefit of LIMs is their ability to produce direct linear motion, eliminating the need for mechanical conversion systems. They are also frictionless, which results in lower maintenance costs and longer lifespan. Moreover, LIMs are highly scalable; the motor’s thrust can be increased simply by extending the length of the primary.

- Disadvantages: On the downside, LIMs are less efficient than their rotational counterparts due to ‘end effects’ and require more complex control systems. They are also more expensive to manufacture and install.

Conclusion

In conclusion, Linear Induction Motors represent a significant advancement in the field of electric motor technology. Their unique ability to produce linear motion directly from electrical energy has revolutionized various sectors, from transportation to industrial automation. Despite their disadvantages, with ongoing research and advancements, LIMs have the potential to become an even more integral part of our technological landscape. Understanding their principles, applications, and performance factors not only provides insight into this fascinating technology but also opens the door to its potential future advancements and applications.