An iron core choke is a passive electronic component that stores energy in a magnetic field, regulating current flow and filtering high-frequency noise in various applications.

Understanding Iron Core Chokes: Basics, Applications, and Design

Introduction

Iron core chokes are essential components in various electronic devices and power supplies, where they serve as inductors to regulate current flow. This article will discuss the basics of iron core chokes, their applications, and design considerations. By the end of this two-part series, you’ll have a comprehensive understanding of these critical electronic components.

What is an Iron Core Choke?

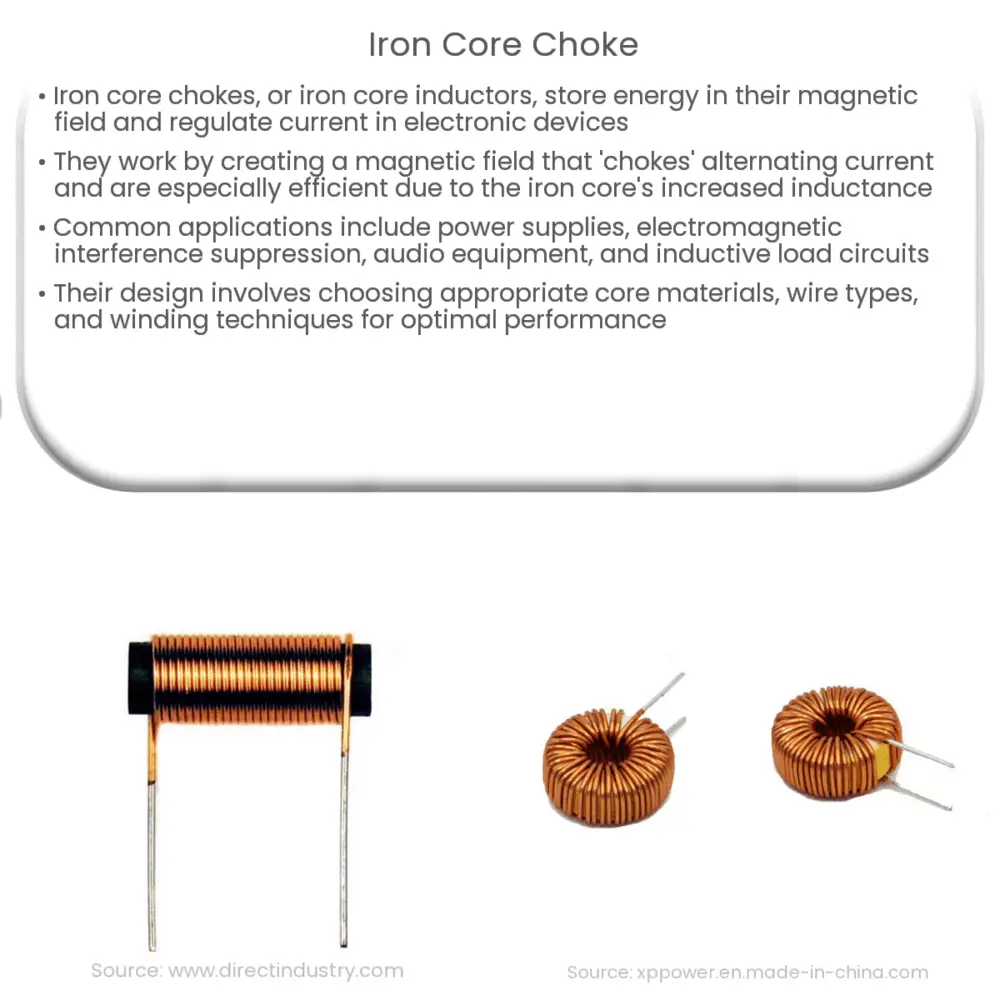

An iron core choke, also known as an iron core inductor, is a passive electronic component designed to store energy in its magnetic field and impede alternating current (AC) while allowing direct current (DC) to pass through. It consists of a coil of insulated wire wound around a magnetic core, typically made of iron or an iron-based material. The inductor’s primary function is to oppose sudden changes in current, which is a valuable property in various electronic applications.

How Iron Core Chokes Work

When a current flows through the coil of an iron core choke, it creates a magnetic field around the coil. This magnetic field, in turn, induces a voltage across the coil. The induced voltage opposes the change in current, effectively ‘choking’ or limiting the alternating current. This phenomenon is known as inductive reactance, and its magnitude depends on the frequency of the alternating current and the inductor’s inductance value.

The presence of the iron core serves to increase the inductor’s inductance value compared to an air core inductor, allowing it to store more energy in its magnetic field. This increased inductance also enhances the choke’s ability to limit high-frequency AC components, making it an effective filter in electronic circuits.

Applications of Iron Core Chokes

Iron core chokes find use in a wide range of applications, including:

- Power Supplies: Iron core chokes are commonly used in switched-mode power supplies (SMPS) to filter out high-frequency noise generated by the switching action. They can also be found in linear power supplies, where they help to reduce output voltage ripple.

- Electromagnetic Interference (EMI) Suppression: Iron core chokes are used in electronic devices to minimize the interference caused by electromagnetic radiation. They suppress high-frequency noise, preventing it from affecting other components or being radiated out of the device.

- Audio Equipment: In audio applications, iron core chokes help to eliminate unwanted high-frequency noise, ensuring clear and crisp sound quality.

- Inductive Load Applications: Iron core chokes are employed in circuits with inductive loads, such as motors and transformers, to limit inrush current and protect the components from damage.

In the second part of this article, we will discuss the design considerations for iron core chokes, including core materials, wire types, and winding techniques. Stay tuned to learn more about these vital electronic components.

Design Considerations for Iron Core Chokes

Core Materials

Choosing the right core material is crucial for the performance of an iron core choke. The most common materials include:

- Soft Iron: Soft iron cores offer high permeability, allowing for high inductance values. They are suitable for low-frequency applications.

- Ferrite: Ferrite cores provide high resistance to eddy currents, making them ideal for high-frequency applications. They also exhibit low core losses and excellent temperature stability.

- Iron Powder: Iron powder cores are an economical choice for high-frequency applications, providing a balance between performance and cost.

Wire Types

The type of wire used for winding the coil impacts the inductor’s resistance and efficiency. Some common wire types include:

- Solid Copper Wire: Solid copper wire offers low resistance and is suitable for low-frequency applications. However, it can be prone to skin effect at high frequencies, causing increased resistance.

- Litz Wire: Litz wire consists of multiple strands of insulated copper wire twisted together. It reduces the skin effect and proximity effect at high frequencies, resulting in lower losses and improved efficiency.

Winding Techniques

Winding techniques play a crucial role in determining the inductance and performance of an iron core choke. Some common winding techniques include:

- Single-Layer Winding: In single-layer winding, the wire is wound in a single layer around the core. This technique offers low cost and ease of manufacturing but may exhibit increased capacitance between the windings.

- Multi-Layer Winding: Multi-layer winding involves winding multiple layers of wire on the core. This approach results in higher inductance values but can also lead to increased capacitance and losses.

- Sectional Winding: Sectional winding divides the coil into several sections, reducing the capacitance between the windings and improving performance at high frequencies.

Conclusion

Iron core chokes are indispensable components in various electronic devices and power supplies, thanks to their ability to regulate current flow and filter out high-frequency noise. Understanding the basics of iron core chokes, their applications, and design considerations will enable engineers and hobbyists to make informed decisions when selecting or designing these critical electronic components. With the right combination of core materials, wire types, and winding techniques, an iron core choke can significantly improve the performance and reliability of an electronic circuit.