ICP accelerometers are advanced vibration sensors that integrate impedance converters and amplifiers, offering compact designs and improved signal integrity.

Integrated Circuit Piezoelectric (ICP) Accelerometer: The Future of Vibration Sensing

In recent years, the world has seen rapid advancements in sensor technology, enabling us to measure and monitor a wide range of physical phenomena with increased precision and reliability. One such development is the Integrated Circuit Piezoelectric (ICP) accelerometer, a cutting-edge innovation in the field of vibration sensing. In this article, we will explore the fundamentals of ICP accelerometers, their applications, and the benefits they offer over traditional accelerometer designs.

Understanding ICP Accelerometers

ICP accelerometers are a type of piezoelectric accelerometer, which means they rely on the piezoelectric effect to measure acceleration. The piezoelectric effect is a phenomenon where certain materials, like crystals, generate an electrical charge when subjected to mechanical stress. In the case of an accelerometer, this stress is created by the vibration or acceleration it is exposed to.

What sets ICP accelerometers apart from other piezoelectric accelerometers is their integration of an impedance converter and an amplifier within the sensor. This integration simplifies the overall design and allows for a more compact, lightweight, and low-power solution, which is essential for many modern applications.

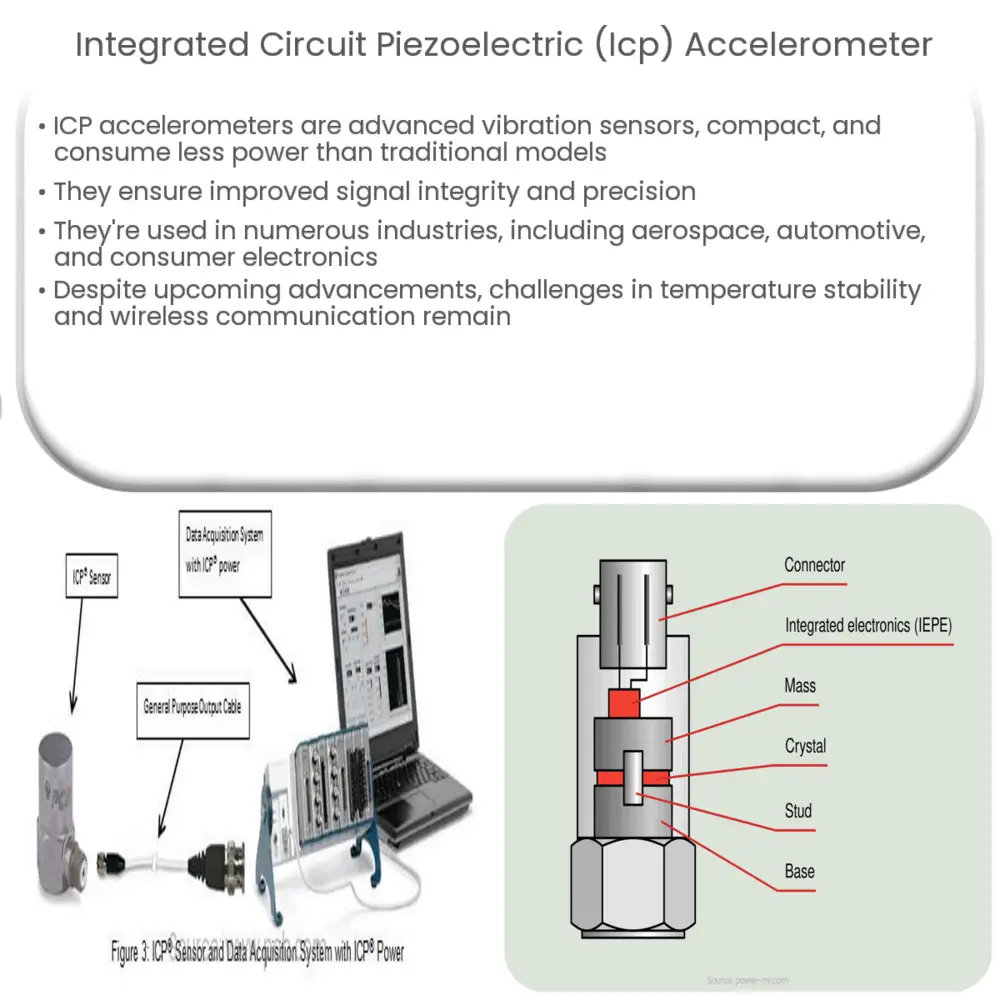

Key Components of an ICP Accelerometer

An ICP accelerometer is primarily composed of three main components:

- Piezoelectric sensing element: This is the core of the accelerometer, and it is responsible for generating an electrical charge proportional to the applied acceleration. The sensing element is typically made from materials like quartz, lead zirconate titanate (PZT), or other piezoelectric ceramics.

- Impedance converter: The impedance converter serves to convert the high-impedance charge generated by the piezoelectric sensing element into a low-impedance voltage signal. This is important because high-impedance signals are more susceptible to noise and interference, which can compromise the accuracy of the accelerometer’s measurements.

- Amplifier: The amplifier’s role is to boost the output signal from the impedance converter, making it suitable for further processing or analysis. In some cases, the amplifier may also include signal conditioning capabilities, such as filtering or analog-to-digital conversion.

Advantages of ICP Accelerometers

ICP accelerometers offer several advantages over traditional piezoelectric accelerometers, such as:

- Compact size and lightweight design: The integration of the impedance converter and amplifier within the sensor allows for a more compact and lightweight form factor, making ICP accelerometers ideal for applications with limited space or weight constraints.

- Improved signal integrity: By converting the high-impedance charge into a low-impedance voltage signal within the sensor, ICP accelerometers are less susceptible to noise and interference, resulting in improved signal integrity and measurement accuracy.

- Lower power consumption: The integrated design of ICP accelerometers typically results in lower power consumption compared to other piezoelectric accelerometers, making them suitable for battery-powered or energy-constrained applications.

Given these advantages, ICP accelerometers are increasingly being adopted across various industries for a wide range of applications, which we will explore in the next section.

Applications of ICP Accelerometers

ICP accelerometers have found numerous applications across various industries due to their versatility, compact size, and high performance. Some of the most prominent applications include:

- Structural health monitoring: ICP accelerometers can be used to monitor the vibrations and stresses in bridges, buildings, and other infrastructure, helping to detect potential structural problems and ensure safety.

- Automotive: In the automotive industry, ICP accelerometers play a crucial role in testing and validating vehicle components, such as engines, suspensions, and exhaust systems, as well as assessing vehicle performance and safety.

- Aerospace: ICP accelerometers are widely used in aerospace applications for vibration testing and analysis of aircraft components, flight data recording, and monitoring the health of satellites and spacecraft.

- Industrial machinery: ICP accelerometers are employed in various industrial applications to monitor the health of rotating machinery, such as motors, pumps, and turbines, facilitating predictive maintenance and reducing equipment downtime.

- Consumer electronics: With the increasing need for compact and low-power sensors in consumer electronics, ICP accelerometers are now being integrated into devices like smartphones, wearables, and gaming consoles to enable motion tracking, navigation, and user interface control.

Future Developments and Challenges

As technology continues to evolve, ICP accelerometers are expected to see further advancements in areas such as miniaturization, sensitivity, and power efficiency. These improvements will help expand their applicability in emerging fields, such as the Internet of Things (IoT), robotics, and biomedical devices.

However, several challenges remain in the development and deployment of ICP accelerometers. One key challenge is the need for improved temperature stability, as variations in temperature can cause changes in the piezoelectric material’s properties, potentially affecting measurement accuracy. Another challenge is the development of more robust and reliable wireless communication protocols, which are essential for remote monitoring and IoT applications.

Conclusion

ICP accelerometers represent a significant step forward in vibration sensing technology, offering numerous advantages over traditional piezoelectric accelerometers, such as compact size, improved signal integrity, and lower power consumption. Their widespread adoption across various industries highlights their versatility and effectiveness in measuring and monitoring vibrations and accelerations. As research and development continue, we can expect to see further advancements in ICP accelerometer technology, enabling even greater performance and unlocking new applications in emerging fields.