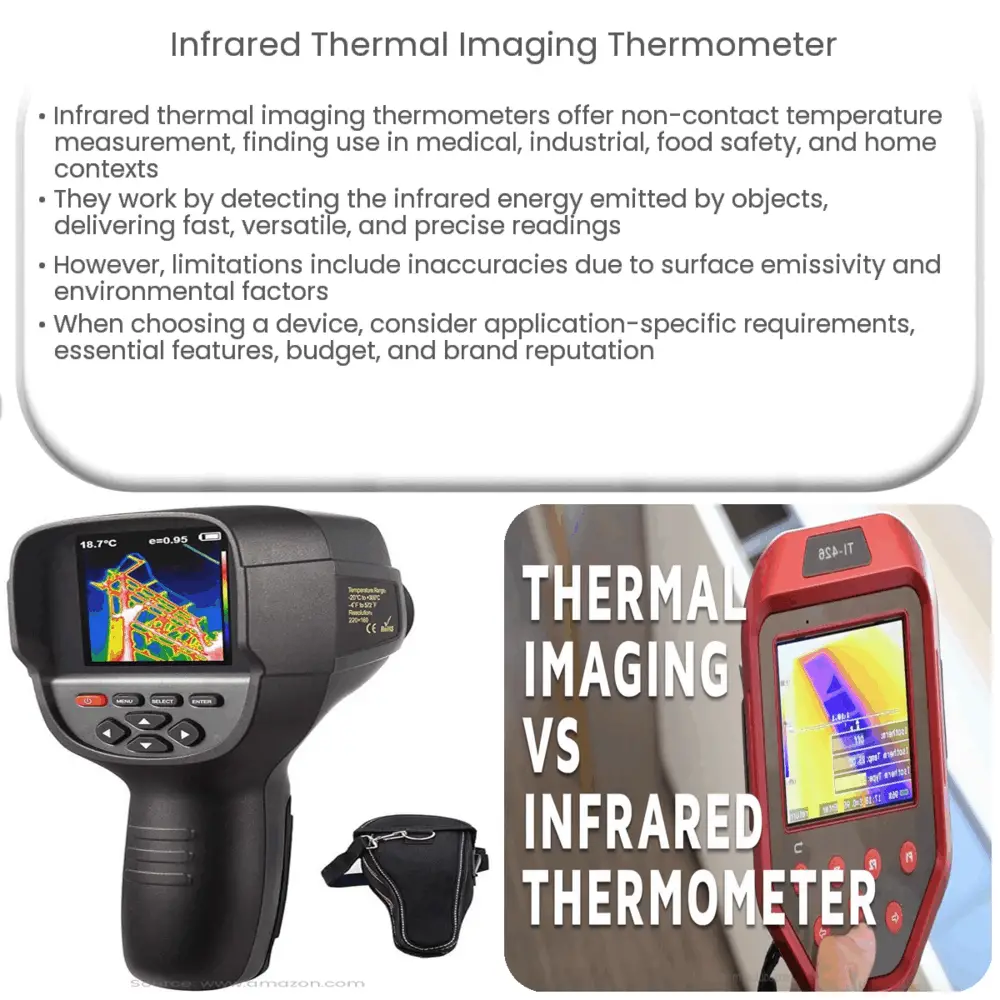

Infrared thermal imaging thermometers offer non-contact, fast, and accurate temperature measurements for medical, industrial, and home use.

Infrared Thermal Imaging Thermometer: Revolutionizing Temperature Measurement

In recent years, infrared thermal imaging thermometers have gained significant attention due to their numerous applications and benefits. From medical and industrial uses to everyday life, these non-contact devices have revolutionized the way we measure temperature. In this article, we will delve into the basics of infrared thermal imaging thermometers, their working principles, and their various applications.

What is an Infrared Thermal Imaging Thermometer?

An infrared thermal imaging thermometer, also known as an infrared camera or thermal camera, is a non-contact device that measures temperature by detecting the infrared energy emitted by an object. Unlike traditional contact thermometers, which require physical contact with the surface to obtain a temperature reading, infrared thermometers can determine temperature from a distance. This key advantage makes them invaluable in various situations where contact measurement is either impractical or unsafe.

How Does an Infrared Thermal Imaging Thermometer Work?

All objects emit infrared radiation based on their temperature, and the intensity of this radiation is directly proportional to the object’s temperature. Infrared thermal imaging thermometers consist of an infrared sensor, which detects the emitted infrared radiation and converts it into an electrical signal. This signal is then processed by the device’s internal circuitry, which calculates the temperature and displays it on a screen or saves it for further analysis.

Most infrared thermometers also incorporate a laser targeting system that helps users aim the device more accurately at the target object. The laser pointer indicates the exact spot where the temperature is being measured, ensuring accurate and consistent readings.

Applications of Infrared Thermal Imaging Thermometers

With their non-contact nature and rapid response time, infrared thermal imaging thermometers have found applications in a wide range of industries and fields. Some of the most notable applications include:

- Medical: In healthcare settings, infrared thermometers are commonly used for fever screening, allowing medical professionals to quickly assess a patient’s temperature without direct contact. This minimizes the risk of cross-contamination and helps contain the spread of infectious diseases.

- Industrial: Infrared thermometers play a critical role in monitoring and maintaining equipment in various industries. They are used to detect overheating or malfunctioning components, measure the temperature of hot surfaces, and ensure proper functioning of machinery, among other tasks.

- Food Safety: In the food industry, infrared thermometers are used to measure the temperature of both raw materials and finished products, ensuring that food is cooked and stored at appropriate temperatures to prevent spoilage and the growth of harmful bacteria.

- Home Use: At home, infrared thermometers can be used to identify energy inefficiencies by detecting heat loss through windows, doors, and insulation. They can also be employed in cooking, gardening, and other household tasks.

In the second part of this article, we will explore the benefits and limitations of infrared thermal imaging thermometers, as well as discuss the factors to consider when choosing the right device for your specific needs.

Benefits of Infrared Thermal Imaging Thermometers

There are numerous benefits associated with the use of infrared thermal imaging thermometers, making them a popular choice in various applications. Some of these benefits include:

- Non-contact Measurement: As infrared thermometers can measure temperature from a distance without physical contact, they prevent cross-contamination and reduce the risk of injury when measuring high temperatures.

- Speed: Infrared thermometers provide temperature readings almost instantaneously, making them ideal for situations that require quick and accurate temperature assessments.

- Versatility: The wide range of applications and industries that utilize infrared thermometers showcases their versatility and adaptability to different settings and requirements.

- Accuracy: When used correctly and calibrated regularly, infrared thermometers can provide highly accurate temperature readings.

Limitations of Infrared Thermal Imaging Thermometers

Despite their numerous benefits, infrared thermal imaging thermometers also have certain limitations that users should be aware of:

- Surface Emissivity: Infrared thermometers rely on the emissivity of the object being measured, which can vary depending on its material and surface characteristics. Some surfaces, such as polished metal, can reflect infrared radiation, leading to inaccurate readings. To mitigate this issue, users can adjust the emissivity settings on the device or use a reference material with a known emissivity value.

- Environmental Factors: Environmental conditions, such as dust, smoke, or humidity, can interfere with infrared radiation and affect the accuracy of temperature readings. Users should be mindful of their surroundings when using infrared thermometers.

- Distance-to-Spot Ratio: The distance-to-spot ratio (D:S) of an infrared thermometer determines the size of the area being measured from a specific distance. A larger D:S ratio means a smaller measurement area from a greater distance. Users must ensure they are using the appropriate D:S ratio for their specific application to obtain accurate readings.

Choosing the Right Infrared Thermal Imaging Thermometer

When selecting an infrared thermal imaging thermometer, there are several factors to consider to ensure you choose the right device for your needs:

- Application: Consider the specific requirements of your application, such as temperature range, accuracy, and distance-to-spot ratio.

- Features: Determine which features are essential for your needs, such as adjustable emissivity, data logging, and image capture.

- Budget: Infrared thermometers are available at various price points, so find one that fits your budget without compromising on the necessary features and quality.

- Brand Reputation: Choose a reputable brand known for producing reliable and accurate infrared thermometers to ensure long-term performance and support.

In conclusion, infrared thermal imaging thermometers have become an invaluable tool in various industries due to their non-contact nature, speed, and accuracy. By understanding their benefits, limitations, and considering the factors mentioned above, you can select the ideal device for your specific application.