Infrared moisture sensors provide accurate, non-destructive, real-time moisture measurements, optimizing processes across various industries.

Infrared Moisture Sensor: An Overview of Applications and Benefits

In recent years, the importance of accurate and efficient moisture sensing has grown significantly, particularly in industries like agriculture, food processing, and pharmaceuticals. Infrared moisture sensors are a crucial technology in meeting these demands. In this article, we explore the underlying principles of infrared moisture sensors, their various applications, and the benefits they offer.

How Infrared Moisture Sensors Work

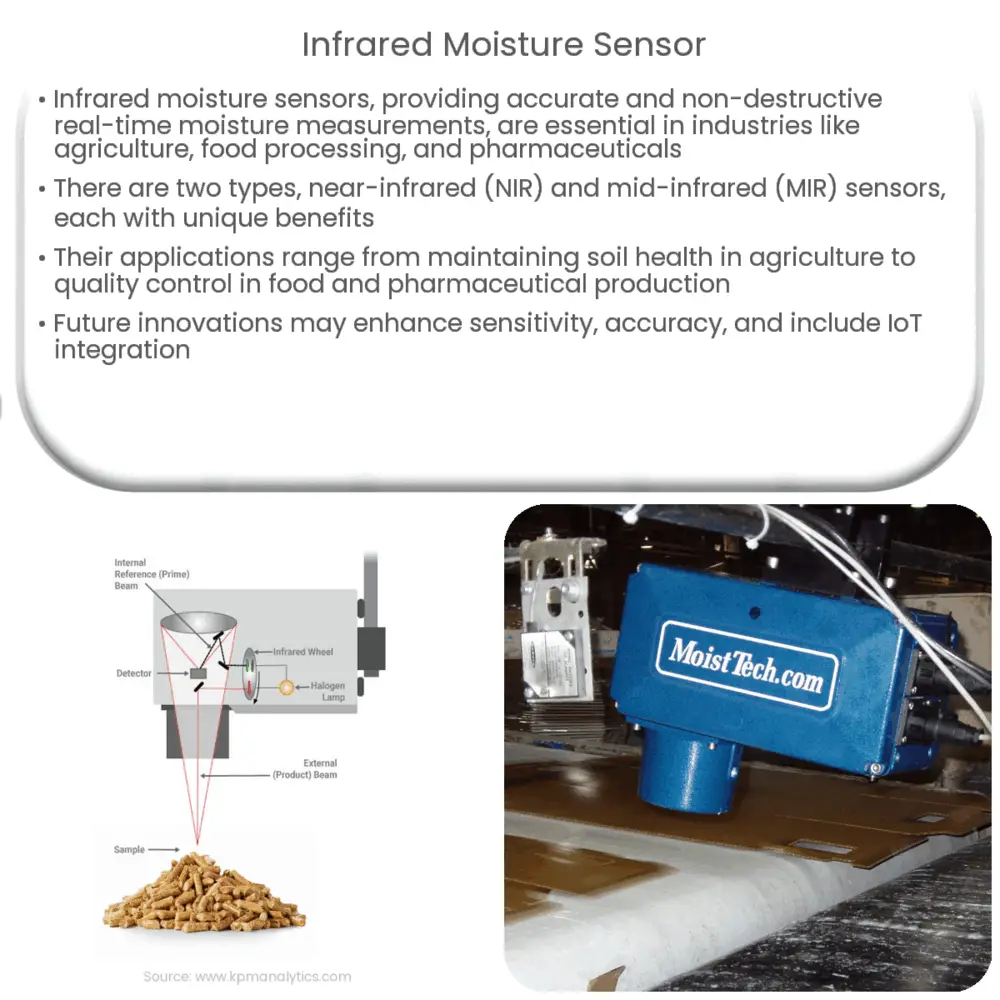

Infrared moisture sensors operate by using infrared light to determine the moisture content in a given material. These sensors emit infrared light at specific wavelengths, which is absorbed by the water molecules present in the material. The level of absorption is directly proportional to the moisture content. By measuring the intensity of the reflected light, the sensor can calculate the material’s moisture level with high accuracy.

There are two primary types of infrared moisture sensors: near-infrared (NIR) and mid-infrared (MIR). NIR sensors are more commonly used for their cost-effectiveness and rapid response times, while MIR sensors are more sensitive and provide higher accuracy, making them suitable for more demanding applications.

Applications of Infrared Moisture Sensors

Infrared moisture sensors are versatile and have found applications across various industries. Some of the most common use cases include:

- Agriculture: Moisture sensors are essential for ensuring proper irrigation, optimizing crop growth, and maintaining soil health. NIR sensors are commonly used for measuring soil moisture levels and determining the optimal time for irrigation.

- Food Processing: Ensuring the right moisture content in food products is crucial for quality control and food safety. Infrared moisture sensors help monitor and control moisture levels in food products during production, packaging, and storage processes.

- Pharmaceuticals: Moisture content plays a vital role in the stability and efficacy of pharmaceutical products. Infrared moisture sensors are used for quality control, ensuring the appropriate moisture levels are maintained throughout the manufacturing process.

- Wood and Paper Industry: Controlling moisture levels is essential for preventing warping, cracking, and other issues in wood and paper products. Infrared moisture sensors help monitor and maintain optimal moisture levels during production, storage, and transportation.

Benefits of Infrared Moisture Sensors

Implementing infrared moisture sensors in various industries offers numerous benefits:

- Accuracy: Infrared moisture sensors provide highly accurate measurements, enabling precise control of moisture levels and ensuring consistent product quality.

- Real-time Measurements: These sensors offer rapid response times, allowing real-time monitoring and adjustment of moisture levels during production processes.

- Non-destructive Testing: Infrared moisture sensors measure moisture content without direct contact, avoiding potential damage to the material being tested.

- Reduced Waste and Energy Consumption: By optimizing moisture levels, infrared moisture sensors can minimize waste and reduce energy consumption in various industries.

In conclusion, infrared moisture sensors are an essential technology for modern industry, offering accurate, non-destructive, and real-time moisture measurements. As the demand for efficient moisture control continues to grow, the adoption of infrared moisture sensors is expected to expand across numerous industries, driving innovation and efficiency improvements.

Factors to Consider when Choosing an Infrared Moisture Sensor

When selecting an infrared moisture sensor for a specific application, several factors should be taken into consideration:

- Sensor Type: Choose between near-infrared (NIR) and mid-infrared (MIR) sensors based on your specific requirements. NIR sensors are more cost-effective and have faster response times, while MIR sensors offer higher accuracy and sensitivity.

- Measurement Range: Ensure the chosen sensor can accurately measure the moisture content within the desired range for your application.

- Environmental Factors: Consider the operating temperature, humidity, and other environmental conditions that may affect the sensor’s performance and durability.

- Integration: Verify that the sensor is compatible with your existing equipment and control systems for seamless integration.

- Cost: Balance between performance, durability, and budget constraints when selecting the most suitable sensor for your application.

Future Developments in Infrared Moisture Sensing

As technology continues to advance, innovations in infrared moisture sensing are expected to emerge. Some potential developments include:

- Improved Sensitivity and Accuracy: Advances in sensor technology may lead to even more precise and reliable measurements, further enhancing the benefits of infrared moisture sensors in various industries.

- Miniaturization: Smaller, more compact sensors could enable new applications, particularly in space-constrained environments, while reducing costs and energy consumption.

- Integration with IoT: Infrared moisture sensors could be integrated with Internet of Things (IoT) technology, enabling remote monitoring and control, as well as the collection and analysis of large volumes of moisture data for improved decision-making.

- Machine Learning and Artificial Intelligence: The combination of infrared moisture sensing with machine learning and artificial intelligence could lead to advanced predictive models, optimizing moisture control and automating adjustments in real-time.

Conclusion

Infrared moisture sensors have become an indispensable technology in various industries due to their accuracy, non-destructive measurement capabilities, and real-time monitoring. As the importance of efficient moisture control continues to grow, these sensors will likely see further advancements and expanded applications. By carefully considering the factors influencing sensor selection and keeping an eye on future developments, organizations can harness the power of infrared moisture sensing to optimize their processes, reduce waste and energy consumption, and improve overall product quality.