Infrared gas sensors detect specific gases with high accuracy, offering advantages in air quality monitoring, industrial safety, and medical applications.

Infrared Gas Sensors: The Science and Applications

Infrared gas sensors are becoming increasingly important in a world where air quality and environmental monitoring are critical for public health, safety, and industrial operations. These sensors are capable of detecting and measuring specific gases with high accuracy, making them indispensable tools for various applications. In this article, we will explore the principles behind infrared gas sensors, their advantages, and some common applications.

Principles of Infrared Gas Sensors

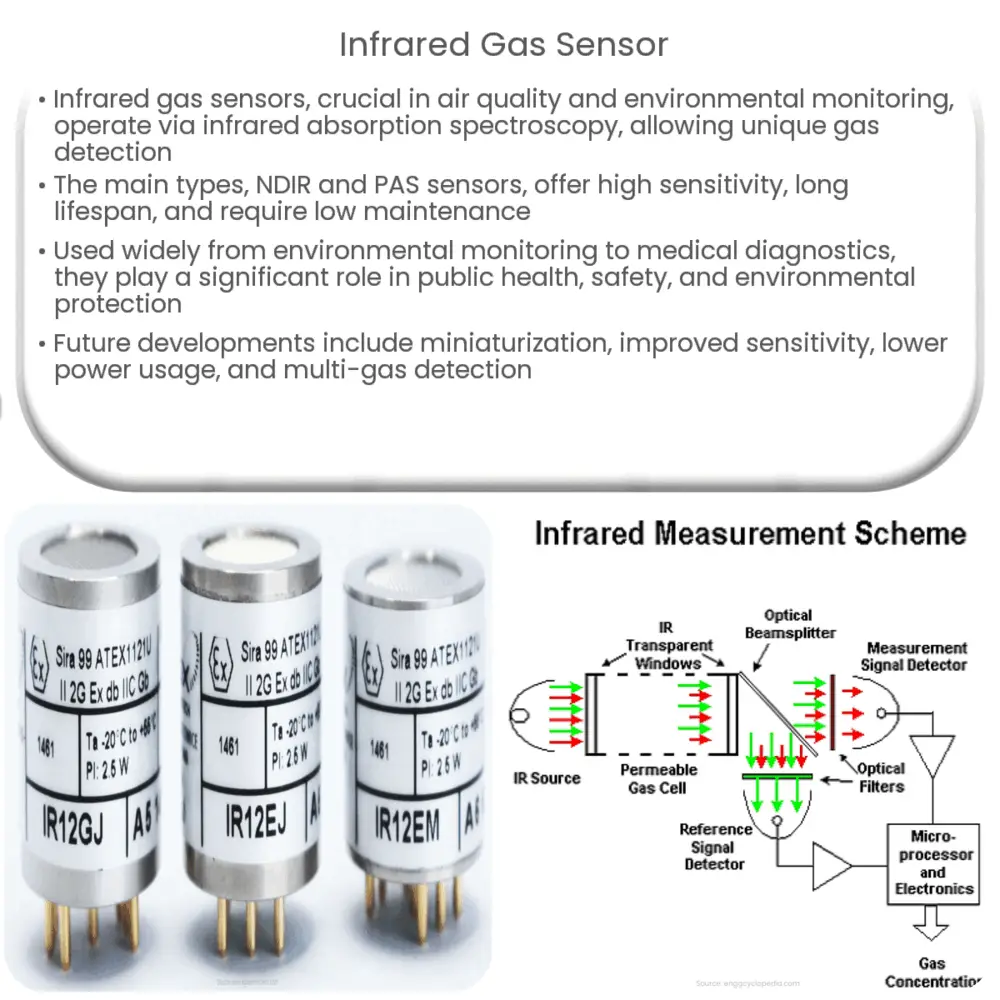

Infrared (IR) gas sensors operate on the principle of infrared absorption spectroscopy. In simple terms, molecules of different gases have unique absorption characteristics when exposed to infrared radiation. When IR light passes through a gas mixture, each gas absorbs specific wavelengths of light, creating a unique “fingerprint” that can be detected and measured by the sensor.

The two main types of infrared gas sensors are Non-Dispersive Infrared (NDIR) and Photoacoustic Spectroscopy (PAS) sensors. NDIR sensors utilize a broadband infrared source, a gas sample chamber, and an infrared detector. The IR light passes through the gas sample, and the detector measures the intensity of the transmitted light. The concentration of the target gas can be calculated by comparing the intensity of the transmitted light to a reference signal.

PAS sensors, on the other hand, are based on the photoacoustic effect. When a gas absorbs infrared radiation, it undergoes a pressure change due to the energy conversion from absorbed light to heat. The pressure change generates an acoustic signal that can be detected and measured by a sensitive microphone. The amplitude of the acoustic signal is proportional to the concentration of the target gas.

Advantages of Infrared Gas Sensors

There are several advantages to using infrared gas sensors, including:

- High sensitivity and selectivity: Infrared gas sensors can detect specific gases with high accuracy due to their unique absorption characteristics, minimizing the risk of false alarms.

- Long lifespan: Unlike other gas sensing technologies, such as electrochemical or metal oxide semiconductor sensors, infrared gas sensors have no consumable parts and experience minimal degradation over time.

- Low maintenance: Infrared gas sensors require minimal maintenance, as they are not affected by dust, humidity, or other environmental factors, and do not require periodic calibration.

- Fast response time: Infrared gas sensors can detect and measure gas concentrations rapidly, often within seconds, enabling real-time monitoring and control of gas levels.

Common Applications of Infrared Gas Sensors

Infrared gas sensors are employed in a wide range of applications, such as:

- Environmental monitoring: These sensors can be used to monitor air quality in urban areas, detecting harmful gases like carbon monoxide, nitrogen dioxide, and sulfur dioxide.

- Industrial safety: Infrared gas sensors can detect and monitor the presence of hazardous gases in industrial settings, ensuring worker safety and preventing accidents.

- Leak detection: Infrared sensors can identify gas leaks in pipelines, storage facilities, and industrial plants, allowing for prompt repairs and minimizing the risk of environmental damage or explosions.

- Automotive emissions: Infrared gas sensors are used to measure and control exhaust emissions from vehicles, helping to reduce air pollution and comply with emissions regulations.

- Medical applications: These sensors can be used to monitor and measure various gases in patients’ breath for diagnostic purposes, such as detecting asthma, diabetes, or infections.

- Greenhouse gas monitoring: Infrared sensors play a crucial role in monitoring and quantifying greenhouse gas emissions from various sources, aiding in the fight against climate change.

Future Developments in Infrared Gas Sensors

As the demand for accurate and reliable gas sensing technologies grows, researchers and manufacturers are continuously working to improve the performance and capabilities of infrared gas sensors. Some areas of focus include:

- Miniaturization: Developing smaller and more compact sensors that can be integrated into portable devices and wearables, allowing for personal monitoring and increased deployment in various environments.

- Improved sensitivity and selectivity: Enhancing the performance of infrared gas sensors to detect and differentiate between a wider range of gases, even in complex gas mixtures or at low concentrations.

- Lower power consumption: Designing sensors that require less power to operate, making them more suitable for battery-powered and energy-harvesting applications.

- Multi-gas detection: Developing sensors capable of detecting multiple gases simultaneously, simplifying monitoring and control systems while providing more comprehensive information about the monitored environment.

Conclusion

Infrared gas sensors are a vital component in numerous applications, from environmental monitoring and industrial safety to medical diagnostics and automotive emissions control. With their high sensitivity, selectivity, and long lifespan, these sensors offer significant advantages over other gas sensing technologies. As research and development continue to advance, infrared gas sensors will likely become even more versatile and essential in our efforts to protect public health, ensure safety, and mitigate environmental impacts.