Explore the world of Inductive Proximity Sensors, their working principle, types, applications, advantages, and the future outlook in our comprehensive guide.

Understanding Inductive Proximity Sensors

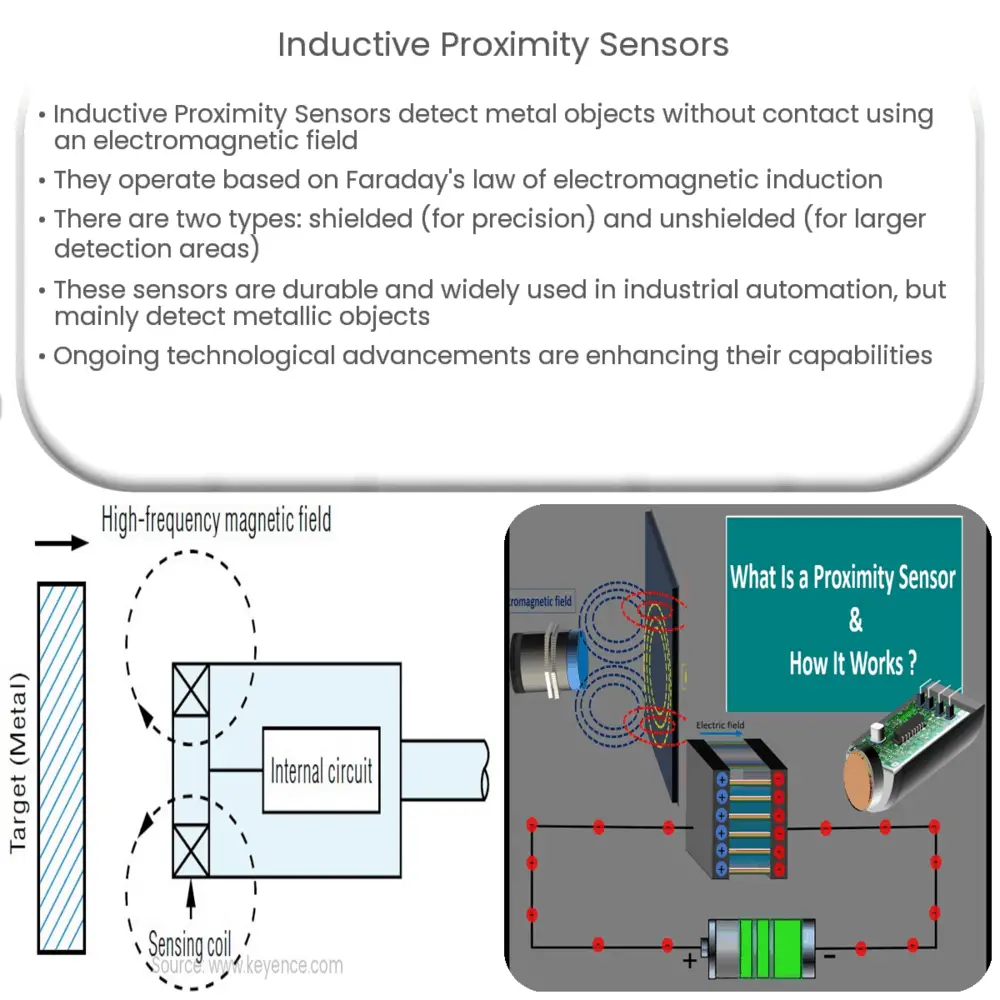

Inductive Proximity Sensors, a key technology in automation systems, are primarily used to detect metal objects without physical contact. These sensors generate an electromagnetic field via an inductor or coil in their design. When a metal object comes close enough, it disrupts this field, triggering a change in the sensor’s output.

The Basic Principle of Operation

An Inductive Proximity Sensor functions based on Faraday’s law of electromagnetic induction. The sensor includes a high-frequency oscillator that creates a constant electromagnetic field when a power supply is connected. The oscillator is made of a coil (or winding), a capacitor, and an amplifier. A metal object entering the electromagnetic field will cause eddy currents to flow on its surface, causing a loss in energy and hence a change in the sensor’s output.

Types of Inductive Proximity Sensors

Application of Inductive Proximity Sensors

Inductive Proximity Sensors have found wide-ranging applications due to their durability, reliability, and non-contact operation. They are used extensively in industrial automation for tasks such as detecting the presence of metal objects in assembly lines, counting parts, or determining the position of machine components.

The Advantages of Inductive Proximity Sensors

Challenges and Limitations

Despite their many advantages, Inductive Proximity Sensors are not without limitations. They are designed to detect metallic objects and cannot identify non-metallic materials like plastic, glass, or wood. The range of detection is also relatively short, typically a few millimeters to a couple of centimeters. Furthermore, the presence of other metallic objects in the vicinity can sometimes cause false triggering.

Advanced Developments

Technological advancements are addressing some of the limitations of traditional Inductive Proximity Sensors. For instance, ‘Factor 1’ sensors can detect all metals at the same range, reducing problems caused by different metal types. Similarly, ‘Extended Range’ sensors have significantly greater detection ranges, expanding the use cases for these sensors.

Choosing the Right Inductive Proximity Sensor

Choosing the right sensor depends on your specific needs and the demands of your application. Key factors to consider include the type of metal to be detected, the required sensing range, the environmental conditions, and the physical size of the sensor. By understanding these aspects, one can select the most suitable inductive proximity sensor.

Conclusion

Inductive Proximity Sensors play a vital role in the world of automation, providing reliable, non-contact detection of metallic objects. While they have certain limitations, ongoing technological advancements are extending their capabilities and range of applications. Their durable nature and resistance to environmental conditions make them a robust choice for many industrial settings. With a proper understanding of their working principle, types, advantages, and limitations, users can harness the power of these sensors to improve automation and increase efficiency in their processes.