Explore the world of Inductive Fault Detectors, their working principle, advancements, applications, and future prospects in our detailed guide.

Introduction to Inductive Fault Detectors

Inductive fault detectors play a critical role in our increasingly electronic and interconnected world. They serve a fundamental function in detecting and diagnosing faults in electrical systems, particularly in the realm of power transmission and distribution.

Working Principle of Inductive Fault Detectors

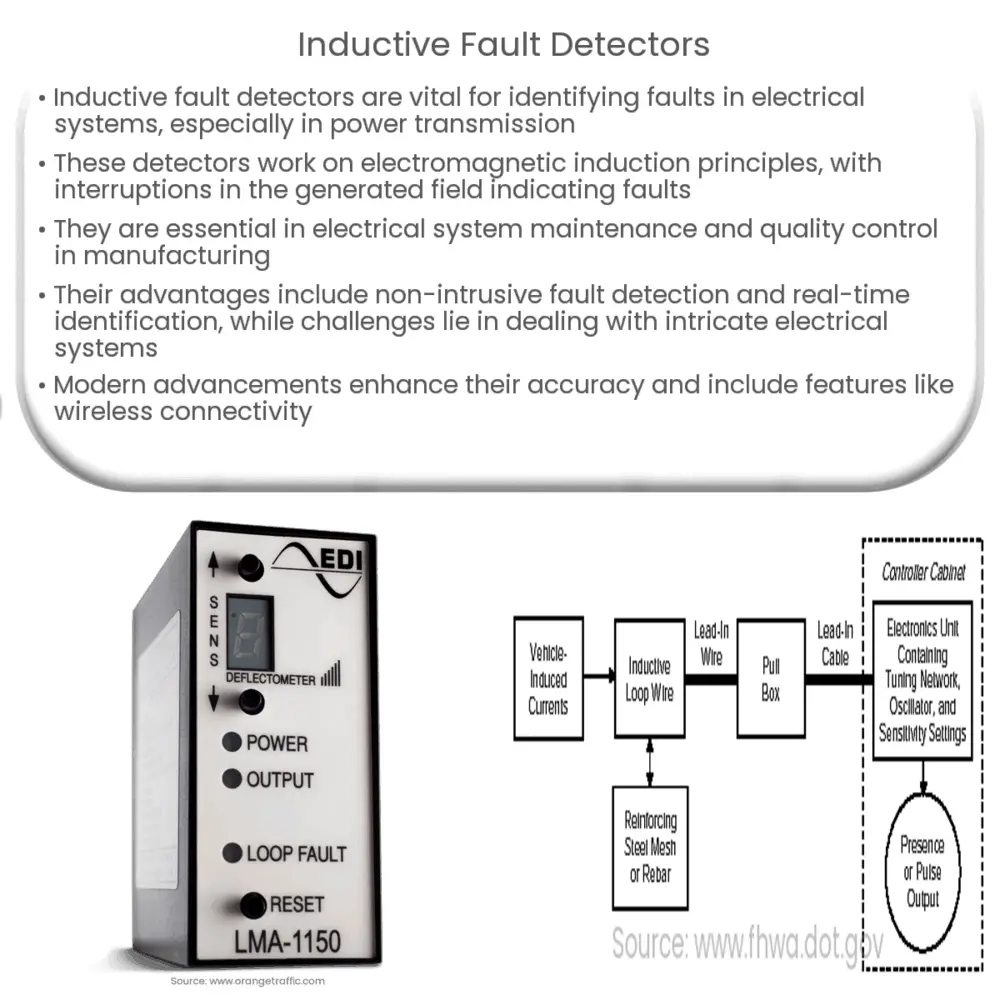

The concept behind inductive fault detection revolves around the principles of electromagnetic induction. An inductive fault detector usually consists of an inductive probe, an amplifier, and a display or indicator. The probe generates an electromagnetic field, and any interruption or anomaly in this field, typically due to faults in the electrical system, is detected and amplified.

Applications of Inductive Fault Detectors

-

The primary application of inductive fault detectors is in the maintenance and repair of electrical systems. By identifying faults early, these devices help prevent potential system failures, thereby saving time and resources.

-

Inductive fault detectors are also used extensively in quality control and testing in manufacturing industries. They ensure that the electrical components and products meet the required standards and specifications.

Advantages of Inductive Fault Detectors

-

The primary advantage of inductive fault detectors is their ability to detect faults non-intrusively, without the need for physical contact with the electrical system. This makes them particularly useful for diagnosing faults in inaccessible or dangerous locations.

-

Another significant benefit is their ability to identify faults in real-time, allowing for prompt action to be taken. This not only minimizes the risk of catastrophic system failures but also aids in preventing further damage.

Despite these advantages, inductive fault detectors also have certain limitations. These include issues with sensitivity and accuracy, particularly when dealing with complex electrical systems. However, ongoing advancements in technology and signal processing algorithms are steadily improving these aspects.

Types of Inductive Fault Detectors

Inductive fault detectors come in various types, each designed to address specific applications and environments. These range from handheld devices for field service technicians to sophisticated systems integrated into production lines. The type of detector selected largely depends on the complexity and requirements of the electrical system under investigation.

The following section will delve deeper into the functioning of these detectors, explore some of the key technological advancements in this field, and discuss in detail the future prospects and challenges faced by inductive fault detectors.

Functioning of Inductive Fault Detectors

Most inductive fault detectors function by generating an electromagnetic field through an inductive probe. When this field encounters a fault or irregularity in an electrical system, it induces a voltage that is detected and amplified by the detector. This output is then processed and displayed, giving technicians a clear indication of the fault’s location and nature.

Key Technological Advancements

-

One of the most noteworthy advancements in this field is the integration of digital technology. Modern inductive fault detectors often incorporate digital signal processing, which enhances the sensitivity and accuracy of fault detection.

-

Additionally, many advanced detectors now feature wireless connectivity, enabling real-time data transmission and remote fault diagnosis. This is particularly beneficial in large-scale or hazardous environments, where physical access might be challenging or unsafe.

Future Prospects and Challenges

-

As we move towards an increasingly electrified future, the demand for efficient and accurate fault detection technologies like inductive fault detectors is expected to rise. They will be instrumental in maintaining the reliability and safety of complex electrical systems.

-

However, several challenges need to be addressed. The primary concern is the detectors’ ability to effectively handle the complexity and variability of modern electrical systems. As systems become more intricate, the task of accurate fault detection and diagnosis becomes increasingly demanding.

Conclusion

Inductive fault detectors have proven to be an invaluable tool for ensuring the smooth operation of electrical systems across various industries. From their initial application in power transmission to their current use in diverse fields like manufacturing, aviation, and healthcare, these detectors have made a significant impact.

As technology advances, so do these detectors. With improved sensitivity, accuracy, and the incorporation of digital technologies, inductive fault detectors are becoming more capable and versatile. While they face challenges due to the evolving complexity of electrical systems, the field shows promising potential for future development. As we move forward, it is clear that inductive fault detectors will continue to play a critical role in the maintenance, safety, and efficiency of our ever-electrifying world.